Pneumatic scissors and selvage folding device used in medium width loom

A technology of folding edge device and scissors, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of difficult installation and debugging, affecting production efficiency, inconvenient assembly and debugging, etc., and achieves a compact and light overall structure and improved reed width The effects of versatility, ease of installation and commissioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

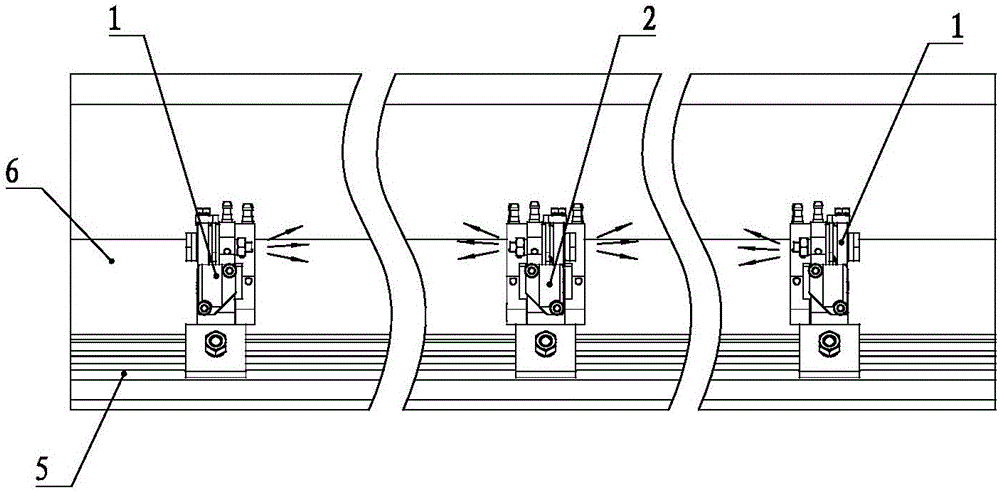

[0031] Such as figure 1 As shown, a pneumatic scissors and tuck-in device applied to a middle-width loom includes two end units respectively arranged on the left and right ends of the sley and an intermediate unit between the two end units, and the two The above-mentioned end units have the same structure and are symmetrically arranged. For the end units, only the end unit at the right end is taken as an example, and its structure will be described in conjunction with the accompanying drawings.

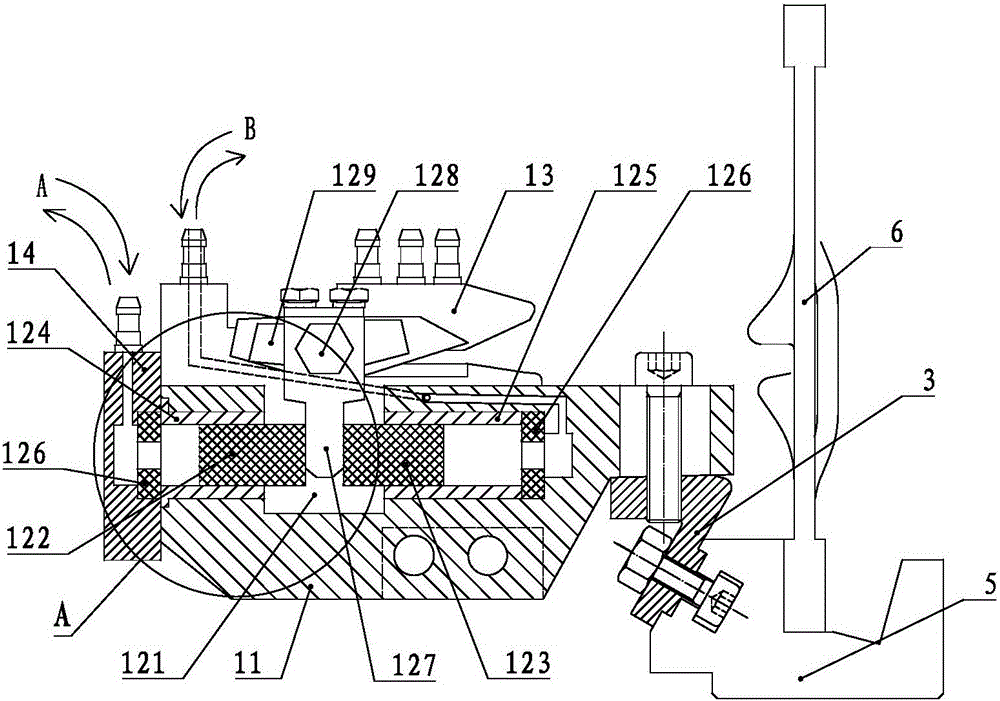

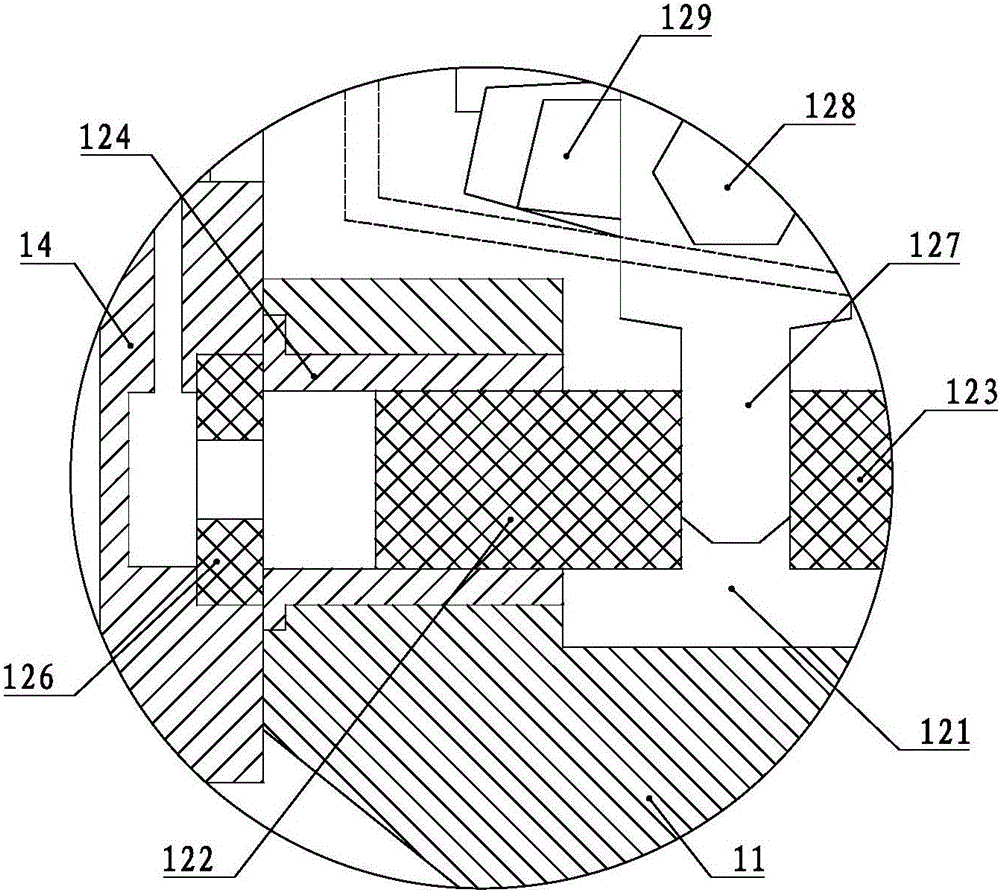

[0032] Such as Figure 4 As shown, the end unit located at the right end of the sley includes a first scissors seat 11 and a first scissors module arranged on the outside of the first scissors seat 11 (with the opposite side of the two end units as the inner side, the same below). and first fold into the block. Such as figure 2 As shown, the first scissors seat 11 is slidingly connected with the sley 5 through the scissors seat fixing block 3, and the scissors seat fixing block 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com