Nail-free seamless one-time forming paper corner frame and manufacturing method thereof

A forming paper, seamless technology, applied in the direction of cardboard items, etc., can solve the problems of high production cost, many processes, and prone to accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

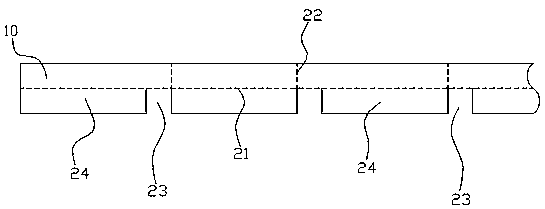

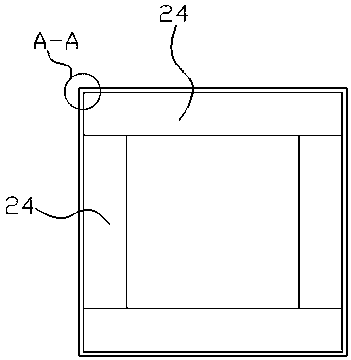

[0031] Example 1: Please see Figure 1 ~ Figure 3 , a nail-free seamless one-time molding paper corner frame, including cardboard 10, the cardboard 10 adopts strip-shaped bobbin paper; the nail-free seamless one-time molding paper corner frame is made of the cardboard 10 spiral Stacking and winding to form a multi-layer structure; the cardboard 10 is coated with an adhesive, and two adjacent layers of cardboard 10 are staggered and bonded to each other through the adhesive.

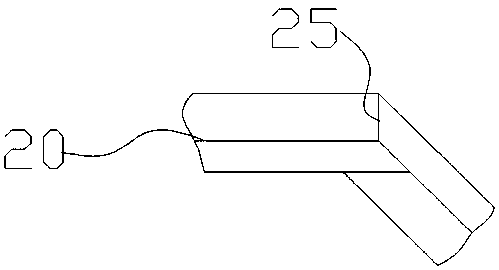

[0032] The cardboard 10 has an indentation 20, and the indentation 20 includes a horizontal indentation 21 and a vertical indentation 22; any side of the horizontal indentation 21 is provided with several punching holes 23, and between the punching holes 23 There is a certain distance; the side with the punching hole 23 is folded along the horizontal indentation 21 to form a folded edge 24, and the cardboard 10 is folded along the vertical indentation 22 to form a folded corner 25, along the The angle fo...

Embodiment 2

[0034] Example 2: Please see figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, a nail-free seamless one-time molding paper corner frame includes cardboard 10, and the cardboard 10 adopts strip-shaped bobbin paper; the nail-free seamless one-time molding paper corner frame is made of the cardboard 10 are spirally stacked and wound to form a multi-layer structure; the cardboard 10 is coated with an adhesive, and two adjacent layers of cardboard 10 are staggered and bonded to each other through the adhesive.

[0035] The cardboard 10 has an indentation 20, and the indentation 20 includes a horizontal indentation 21 and a vertical indentation 22; any side of the horizontal indentation 21 is provided with several punching holes 23, and between the punching holes 23 There is a certain distance; the side with the punching hole 23 is folded along the horizontal indentation 21 to form a folded edge 24, and the cardboard 10 is folded along the vertical indentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com