Bend secondary flow net type or film type liquid purifier

A liquid purification and purifier technology, applied in the field of purifiers, can solve the problems of inability to separate solid particles, frequent filter replacement, easy blockage, etc., and achieve the effects of avoiding blockage, low cost, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

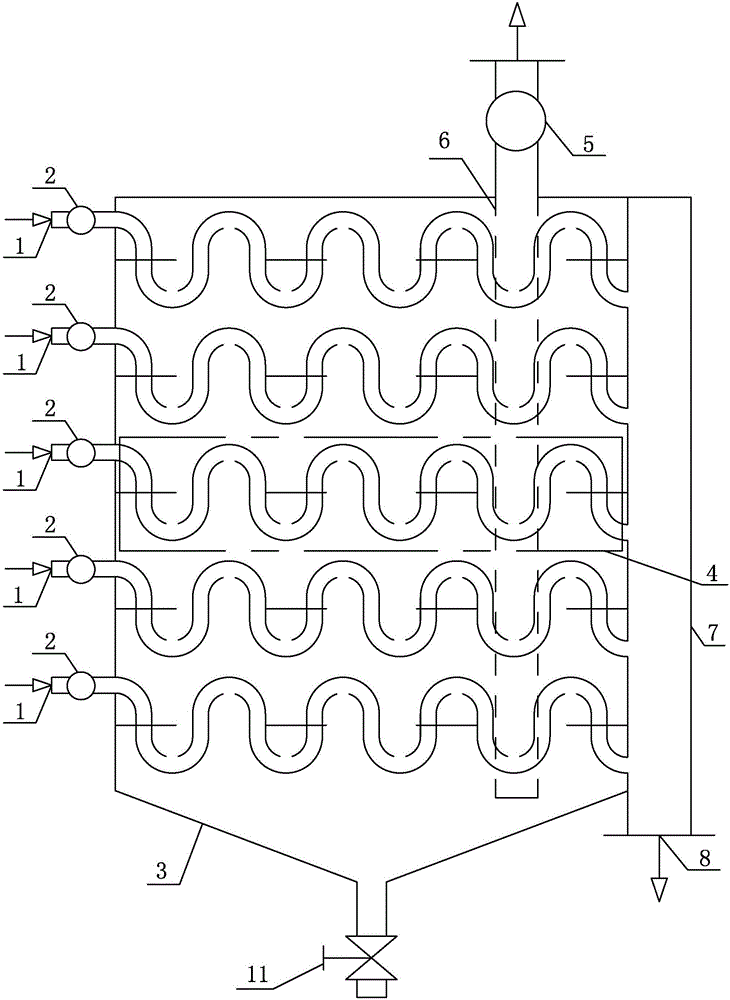

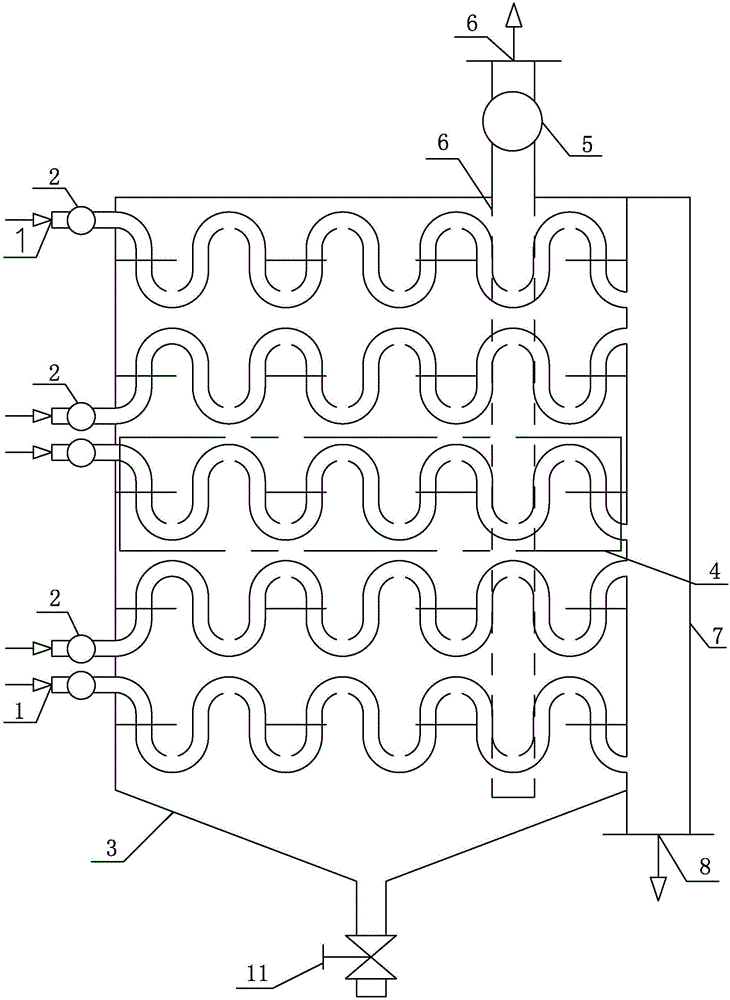

[0012] Specific implementation mode one: combine Figure 1-Figure 5 Illustrate, a kind of bent pipe secondary flow net type or membrane type liquid purifier of this embodiment, it comprises inlet water pump 2, liquid purification chamber 3, static liquid drainage pump 5, static liquid drain pipe 6, blowdown pipe 7 and multiple A secondary flow-net or membrane filter tube 4;

[0013] The outer wall of the liquid purification chamber 3 is arranged with an inlet water pump 2, a static liquid drainage pump 5 and a sewage pipe 7; one end of the sewage pipe 9 is closed and the other end is open, and one end of the static liquid drainage pipe 6 extends into the bottom of the liquid purification chamber 3 , the other end of the static liquid drainage pipe 6 is installed with a static liquid drainage pump 5;

[0014] There are multiple secondary flow-net or membrane filter tubes 4 arranged in the liquid purification chamber 3, and each secondary flow-net or membrane filter tube 4 is a...

specific Embodiment approach 2

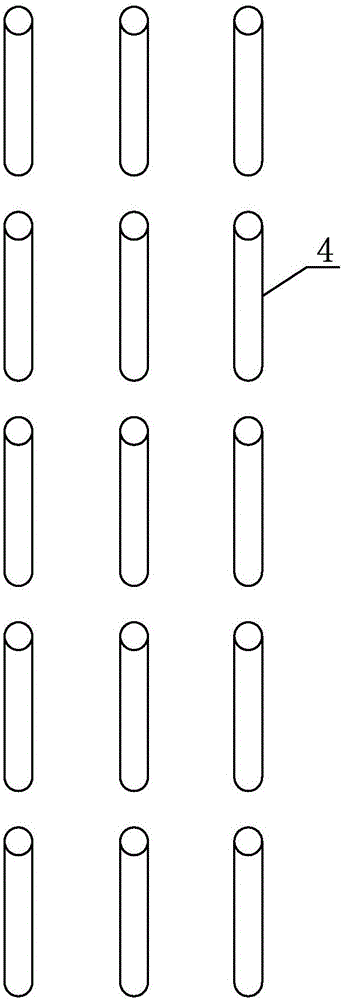

[0016] Specific implementation mode two: combination figure 1 and figure 2 Note that each secondary flow-net or membrane filter tube 4 in this embodiment is arranged horizontally, and multiple secondary flow-net or membrane filter tubes 4 are arranged in a row. With such an arrangement, the structure is simple and the design is reasonable, which can meet the actual separation requirements of gas and solid particles. The quantity of secondary flow net type or membrane filter pipe 4 is preferably 5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 To illustrate, in this embodiment, a plurality of secondary flow-net type or membrane filter tubes 4 arranged in a row are arranged in an array of troughs or crests. With such an arrangement, the structure is simple, the design layout is reasonable, and it can meet the actual separation requirements of gas and solid particles. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com