Method for measuring balance weight and operating parameters of trainer based on reflective type photoelectric sensor

A photoelectric sensor and operating parameter technology, applied in the direction of motion accessories, etc., can solve the problems of exceeding, cumbersome installation, high production and installation requirements, etc., and achieve the effect of convenient use, low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

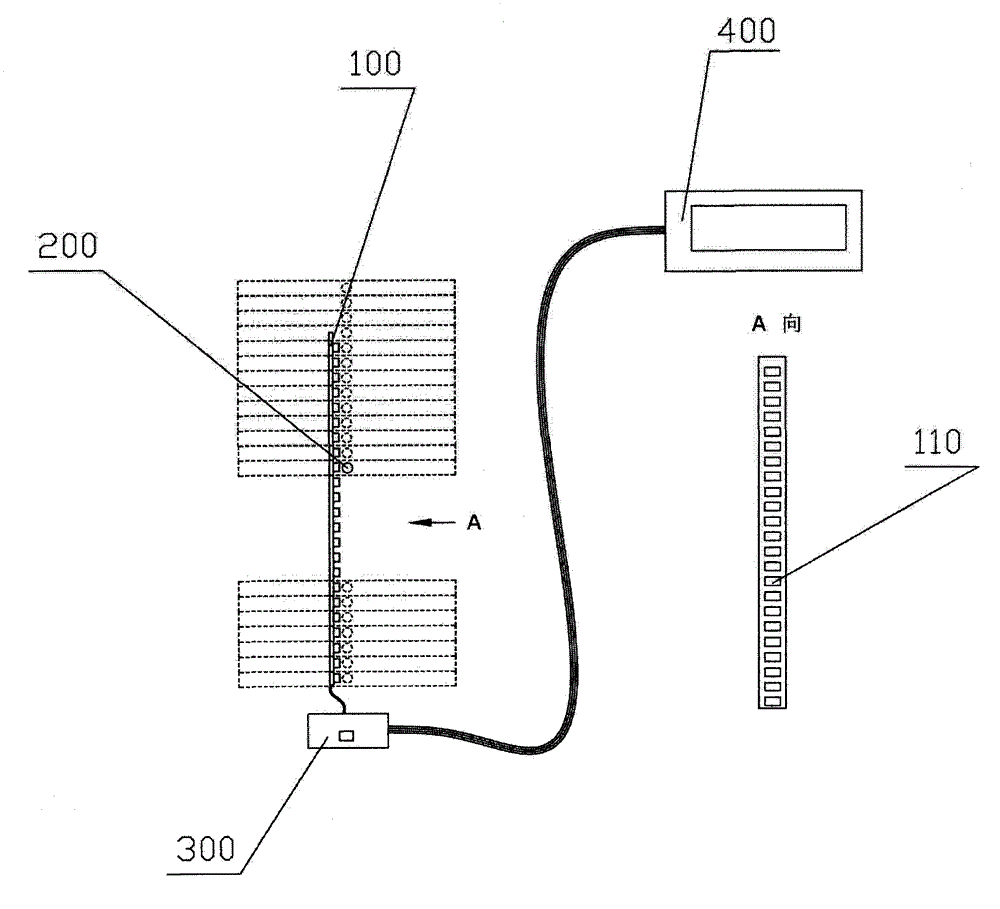

[0010] In order to facilitate further cognition and understanding of the features, purposes and functions of the present invention, the following will be combined with the description attached figure 1 Detailed structure and design concept of the present invention are described, and detailed statement is as follows:

[0011] as attached figure 1 100 refers to reflective photoelectric sensor measuring unit, reflective photoelectric sensor measuring unit 100 vertical counterweight plug 200, parallel counterweights are installed, on the side of counterweight latch 200 tail; when the trainer starts training, first Adjust the position of the counterweight pin 200, insert the counterweight pin 200 into the weight, and the end of the pin is parallel to the reflective photoelectric sensor. The weight moves up and down. When the end of the counterweight pin is perpendicular to the reflective photoelectric sensor, the reflective photoelectric sensor generates an electrical signal. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com