Simple pile head breakdown aided construction method

A construction method and pile head technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as low efficiency, high labor intensity, and difficult chisel removal, and achieve huge economic benefits, less supporting equipment, and reduced The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

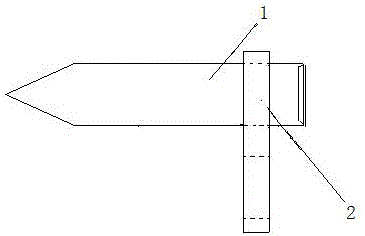

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention is as figure 1 The flow chart is shown.

[0036] The specific steps of a kind of simple pile head breaking auxiliary construction method of the present embodiment are as follows:

[0037] (1) Control the initial setting time of concrete in the later stage

[0038]When the underwater concrete is poured normally, the initial setting time has little to do with the length of the pile or the pouring time, because the concrete at the lower part of the conduit mouth can be solidified in advance, which has a positive effect on the overall pouring quality, especially the stability of the reinforcement cage. It may be necessary to carry out treatment such as tube suspension, and the initial setting time should be 2 to 3 hours.

[0039] (2) Determine the initial setting time of the initial poured concrete

[0040] According to the principle of the conduit method, the underwater concrete poured in the initial stage is just the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com