Special vehicle backboard overturn mechanism

A technology of special vehicles and overturning mechanisms, which is applied in the direction of freight vehicles, motor vehicles, and article transport vehicles, etc., which can solve the problems of inconvenient use, waste of physical strength and manpower, and easy danger, so as to avoid danger and improve work efficiency. Efficiency and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

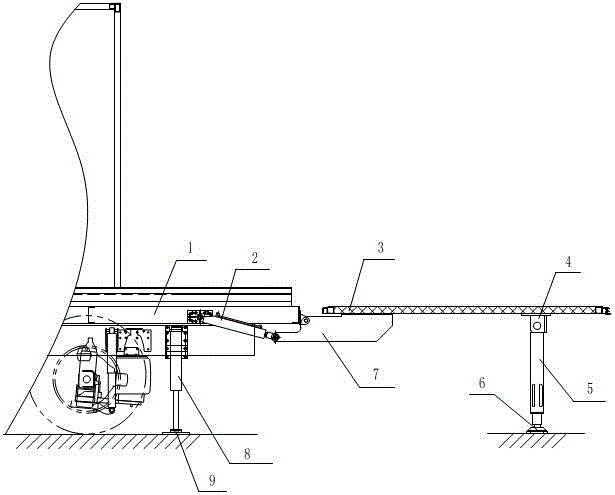

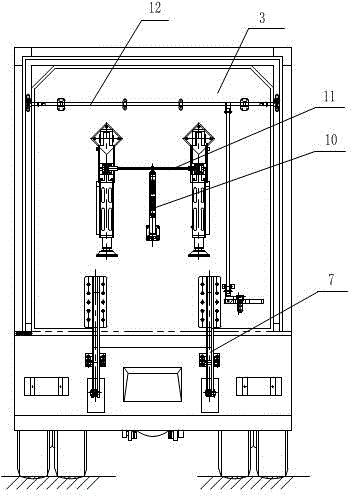

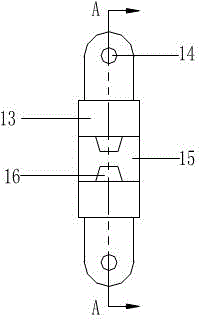

[0016] like figure 1 reconcile figure 2 Shown is a rear plate turning mechanism for a special vehicle, including a turning plate 3 installed on the sub-frame 1, the turning plate 3 is provided with a turning arm 7, and the middle of the turning arm 7 is connected to the auxiliary vehicle The frame 1 is connected in rotation, the sub-frame 1 is provided with an overturning oil cylinder 2, the head of the overturning oil cylinder 2 is connected with one end of the overturning crank arm 7, and the overturning plate 3 is provided with electric support legs, so The electric support leg includes a fixed seat 4 fixed on the flip plate 3, a support rod 5 that can rotate on the fixed seat 4, and a universal foot 6 at the bottom of the support rod 5; A hydraulic support leg is provided, and the hydraulic support leg includes a hydraulic cylinder 8 fixed on the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com