Food processing method of food processer

A technology for food processing and cooking machines, applied in the field of cooking machines, can solve the problems of overflow, sticking to the bottom, sticking to the bottom, etc., and achieve the effect of fast curing and even cooking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention relates to a food processing method of a cooking machine, wherein the cooking machine has the functions of cooking porridge and making rice paste, soybean milk, corn juice, vegetable juice and thick soup.

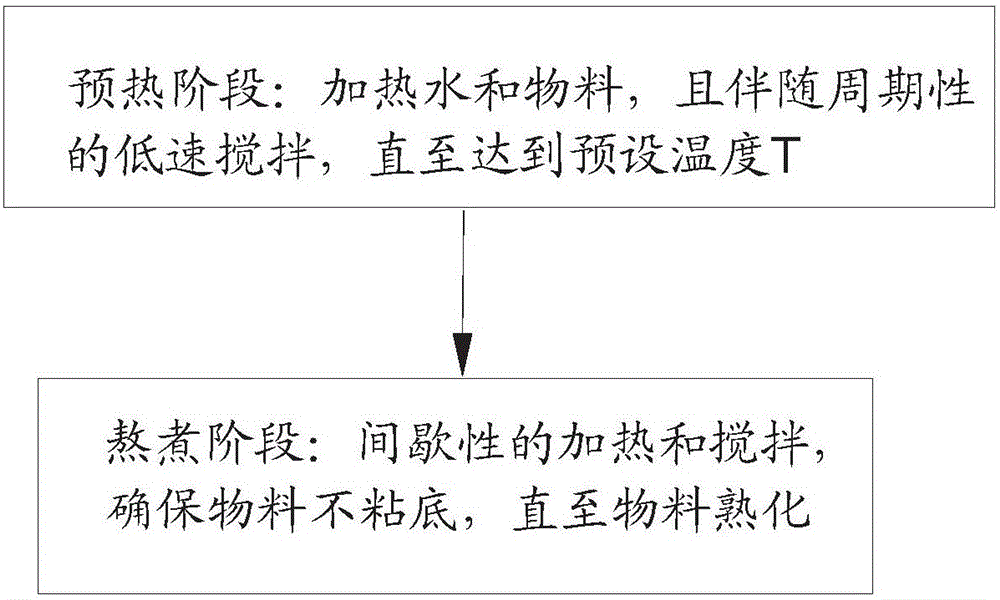

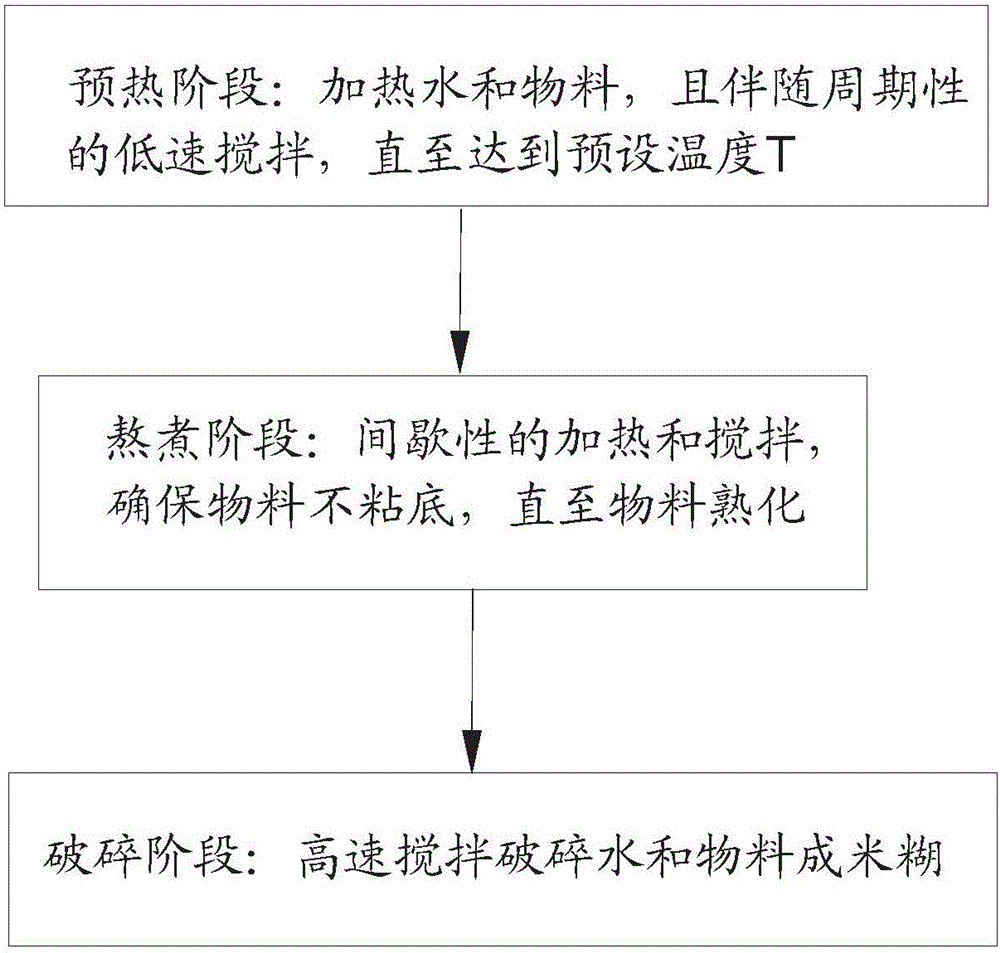

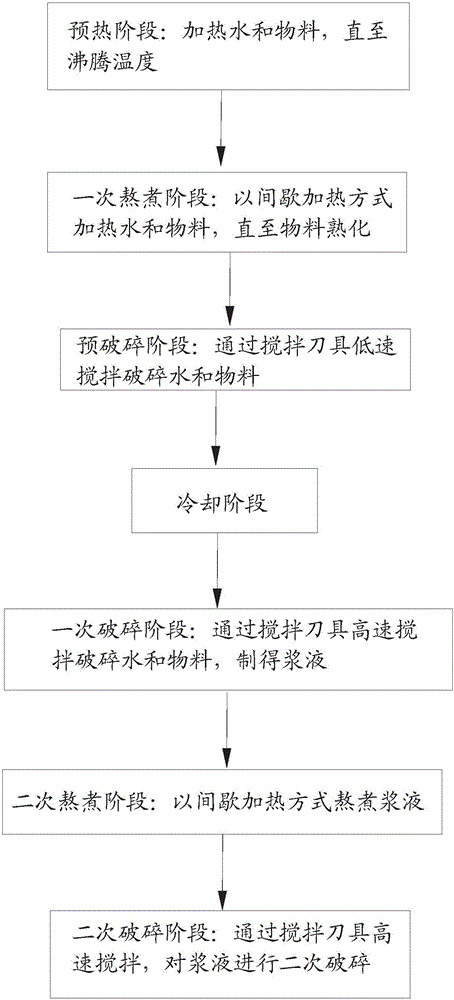

[0034] refer to figure 1 , the cooking machine includes the following working steps in the process of cooking porridge:

[0035] A1. Stir at a low speed in an intermittent cycle of 7s on and 5s off. During the process, the heating element continues to heat the water and materials at full power until the water temperature reaches 94°C to soften the materials;

[0036] A2. Heat for 3 cycles by heating for 15s and stopping for 3s, then add 1s of low-speed stirring, and then stop for 15s;

[0037] A3. Heat for 3 cycles by heating for 11s and stopping for 5s, then add 1s of low-speed stirring, and then stop for 15s;

[0038] A4. Heat for 4 cycles by heating for 9s and stopping for 10s, then add low-speed stirring for 1s, and then stop for 15s; cycle like t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com