Double-sided backlight source and double-sided display device

A double-sided display device, backlight technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased energy consumption, thicker thickness, and high noise, and achieve increased energy consumption and noise, and the whole machine is light and thin. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

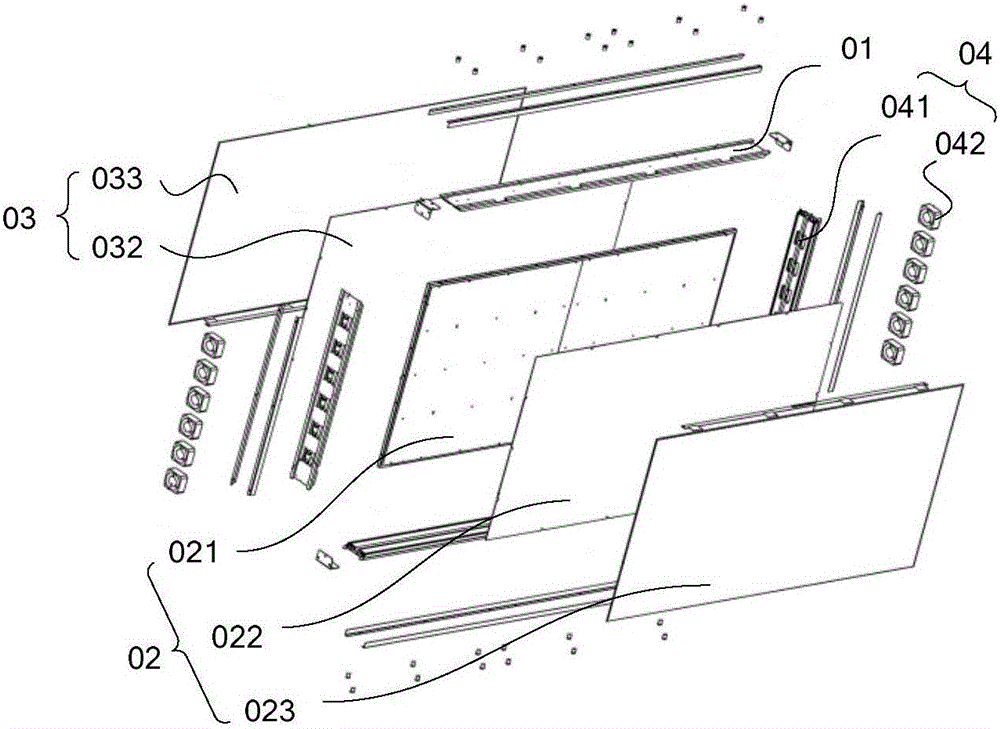

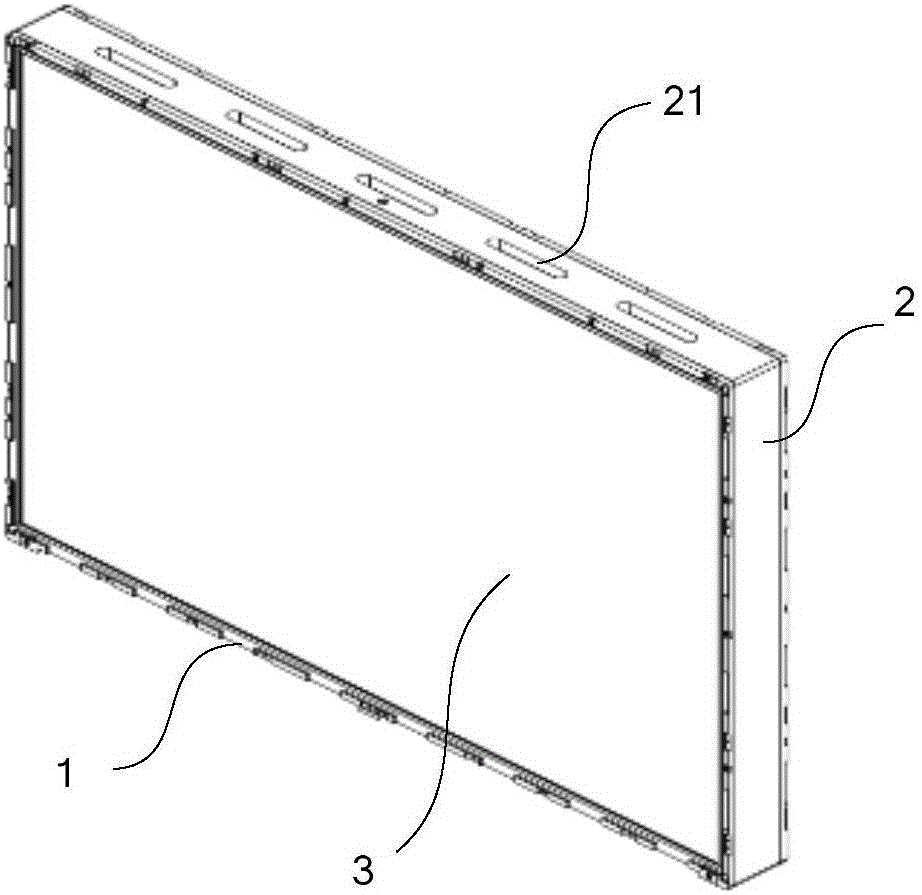

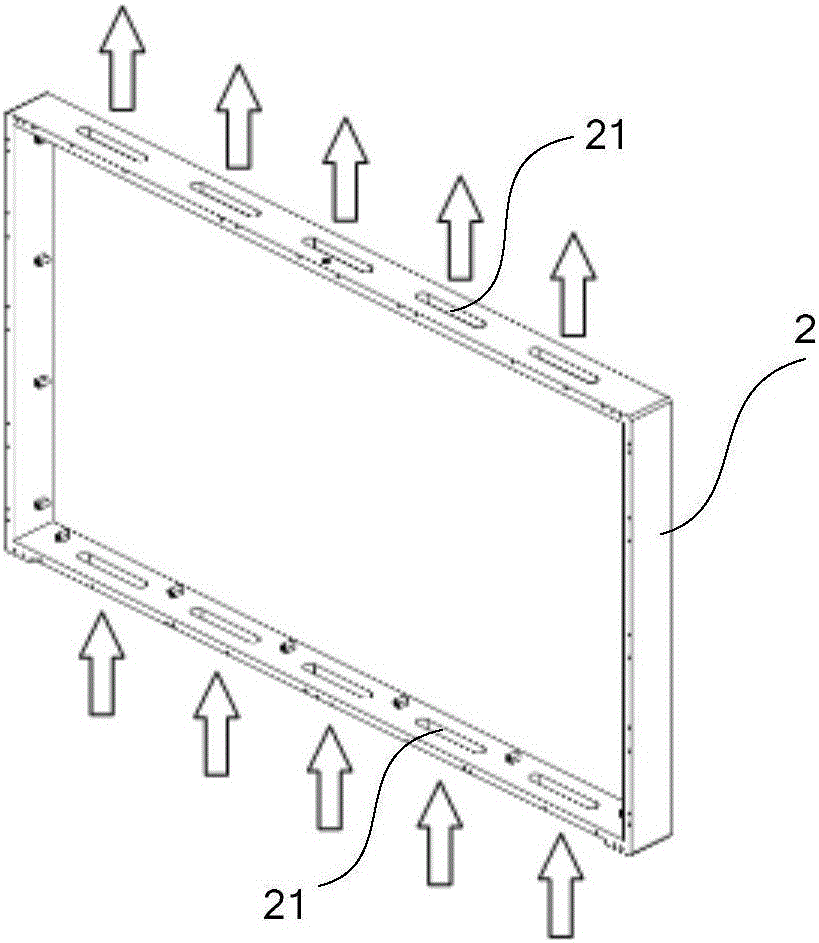

[0030] Such as Figure 4 and Figure 5 As shown, the backlight module 3 is a direct-type backlight module, and the light source 31 includes a heat sink 311 made of heat-conducting material and a first lamp board 312 and a second lamp board 313 arranged on both sides of the heat sink 311. Point light sources are distributed on the lamp board 312 and the second lamp board 313 , and the position of the ventilation hole 21 corresponds to that of the heat sink 311 . Such as Figure 5 As shown, the first lamp board 312 and the second lamp board 313 are distributed with point light sources, which are arranged on both sides of the cooling frame 311, which can respectively provide light sources for both sides of the cooling frame. A large amount of heat generated by the point light sources on the first lamp board 312 and the second lamp board 313 is dissipated through conduction and radiation, and then the heat is dissipated through the heat dissipation channel.

[0031] It should b...

Embodiment 2

[0037] Such as Figure 7 As shown, the backlight module 3 of this embodiment is a side-type backlight module, the light source 31 includes a light bar 311 ′, and the ventilation hole 21 (not shown in the figure) corresponds to the position of the light bar 311 ′. When the backlight module 3 is a side-entry type, its heat mainly comes from the light bar 311'. Therefore, in order to effectively dissipate heat from the backlight module 3, the position of the ventilation hole 21 corresponds to the position of the light bar 311', so that the light bar is in a heat dissipation position. channel.

[0038] Specifically, in order to enable the light source 31 to provide backlight for double-sided display, such as Figure 7 As shown, the backlight module 3 includes a first light guide plate 32' and a second light guide plate 33', the light incident surfaces of the first light guide plate 32' and the second light guide plate 33' are opposite to the light bar 311', The light emitting su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com