A measuring device for mid-infrared blazed grating diffraction efficiency

A diffraction efficiency and measurement device technology, applied in the direction of testing optical performance, etc., can solve problems such as center wavelength drift and inaccurate measurement results, and achieve the effect of reducing measurement errors, complete measurement results, and intuitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

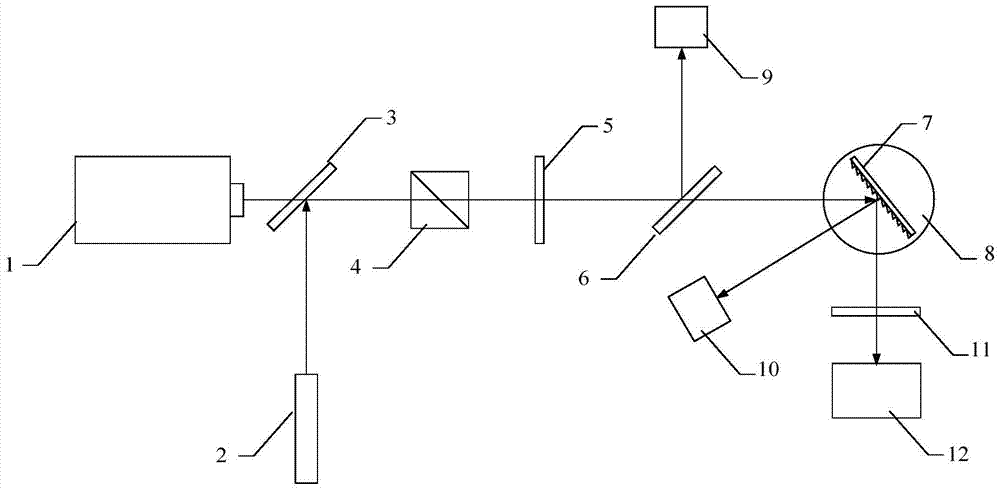

[0023] as attached figure 1 As shown, a measuring device for the diffraction efficiency of a mid-infrared grating is characterized in that the device includes: a tunable mid-infrared laser 1 and a guiding laser 2, and the light emitted by the tunable mid-infrared laser 1 and the guiding laser 2 is respectively irradiated to On both sides of the beam combiner 3, the light combined by the beam combiner 3 passes through the polarizer 4 and the half-wave plate 5 in turn, and then irradiates the polarization beam splitter 6, and the light passing through the polarization beam splitter 6 is divided into two paths, and one path of light enters the The first power meter 9 , the other path of light is diffracted by the grating 7 to be measured and divided into two paths again, one path of diffracted light is input into the spectrometer 12 through the attenuation plate 11 , and the other path of diffracted light enters the second power meter 10 .

[0024] When measuring the first-order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com