Oil quantity detection device for oil disc of sewing machine and sewing machine

A detection device and sewing machine technology, which is applied to sewing machine components, sewing equipment, lubrication/cooling devices, etc., can solve problems such as excessive refueling, neglect, and oil leakage, so as to improve detection accuracy and avoid oil leakage , The effect of consistent motion trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

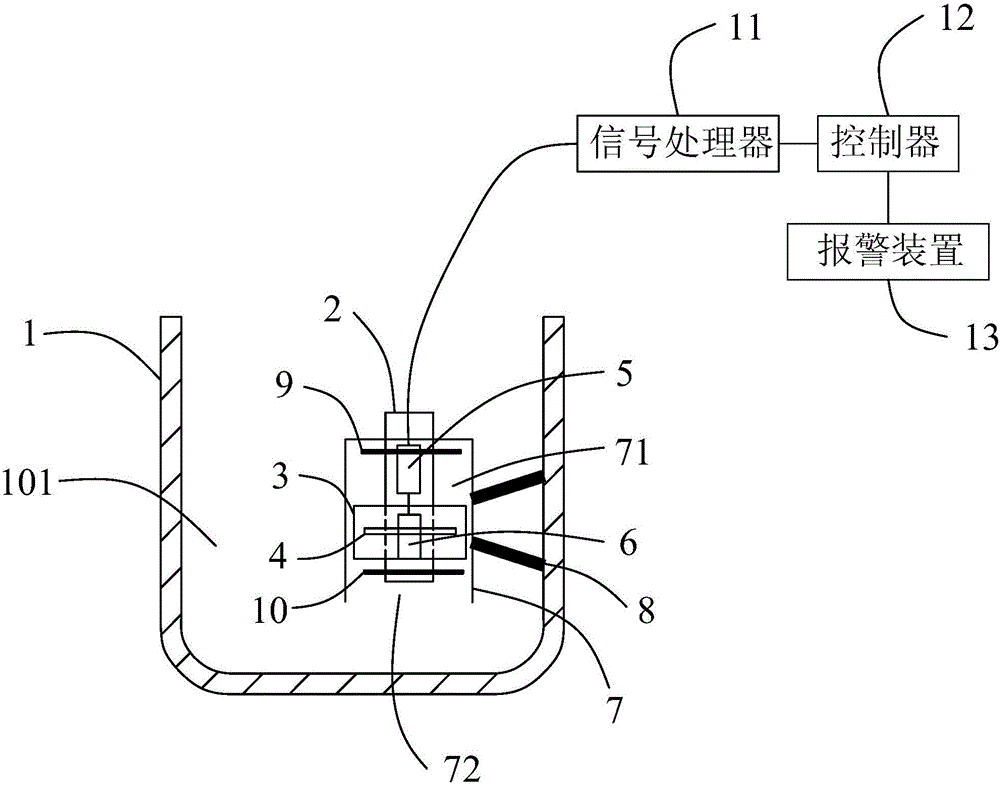

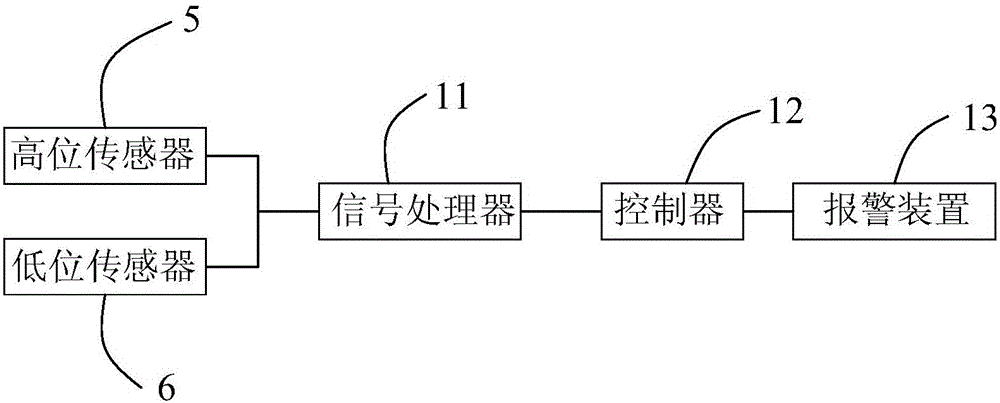

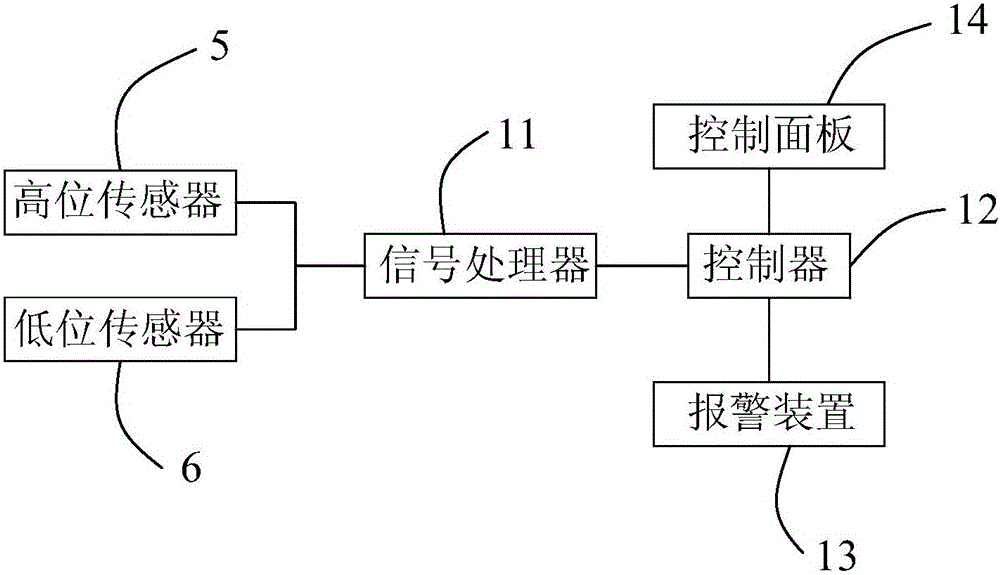

[0057] Embodiment one, as figure 1 As shown, the casing 7 only includes an inverted U-shaped casing body 73, the interior of the casing body 73 forms the inner chamber 71, the opening at the lower end of the casing body 73 forms the oil through hole 72, and the casing body 73 The lower end of the lower end of the oil pan 1 is not in contact with the lower end surface of the oil pan 1 , and the space formed between the two allows the oil to flow into the inner cavity 71 from the oil through hole 72 . The side of the casing body 73 is fixedly connected with the oil pan 1 through at least one fixed connecting rod 8, the fixed connecting rod 8 and the casing 7, the fixed connecting rod 8 and the oil pan 1 can be fixed by screws or welded. . Part of the pillar 2 on which the high sensor 5 and the low sensor 6 are installed is also accommodated in the inner cavity 71 of the casing 7, and the float 3 is sleeved on the pillar 2 and slides up and down along the pillar 2, so the suppor...

Embodiment 2

[0058] Embodiment two, such as Figure 5 As shown, the casing 7 includes an inverted U-shaped casing body 73 and a connecting portion 74 extending straight outward from the lower end of the casing body 73, and the oil hole 72 is opened in the casing body 73 (that is, the casing 7), the connecting portion 74 is welded and fixed to the lower end surface of the oil pan 1 or fixed by fasteners, so that the casing 7 and the oil pan 1 are fixedly connected. The pillar 2 on which the high sensor 5 and the low sensor 6 are installed is also accommodated in the inner chamber 71 of the casing 7, and the float 3 is sleeved on the pillar 2 and slides up and down along the pillar 2, so the pillar 2 is opposite to the up and down of the float 3. The floating plays a guiding role, thereby effectively improving the stability of the float 3 floating up and down, thereby improving the detection accuracy of the oil quantity detection. At the same time, the lower end surface of the pillar 2 and ...

Embodiment 3

[0059] Embodiment three, as Image 6 As shown, the casing 7 includes an inverted U-shaped casing body 73 and a connecting portion 74 extending straight outward from the lower end of the casing body 73, and the oil hole 72 is opened in the casing body 73 (that is, the casing 7), the connecting portion 74 is welded and fixed to the lower end surface of the oil pan 1 or fixed by fasteners, so that the casing 7 and the oil pan 1 are fixedly connected. The pillar 2 on which the high position sensor 5 and the low position sensor 6 are installed is located outside the housing body 73 , and the lower end surface of the pillar 2 is welded or riveted or screwed to the upper end surface of the connecting portion 74 . The signal lines used to connect the high level sensor 5 and the signal processor 11, and the low level sensor 6 and the signal processor 11 go out from the lower end of the oil pan 1 downward, and are routed from the outside of the oil pan 1, so that it is convenient to do ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com