Wheel-beam combined type car frame

A technology of wheel beam frame and frame, which is applied in vehicle parts, substructure, transportation and packaging, etc., can solve the problem of not realizing a new bridge-free structure, and failing to realize electrification, light weight, intelligence, etc. problem, to achieve the effect of low cost, improved utilization of interior space, and lower floor height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

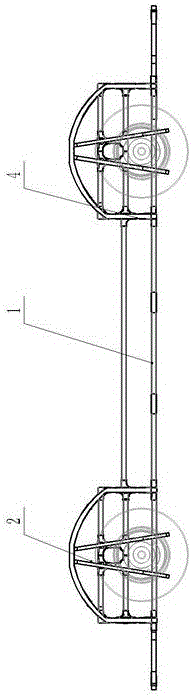

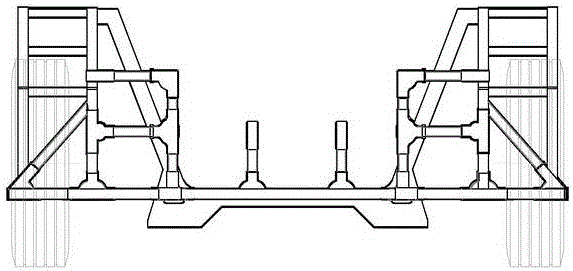

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, this embodiment is composed of longitudinal main beam 1, wheel beam frame 2, cross beam 3 and connector 4, between longitudinal main beam 1 and wheel beam frame 2, between wheel beam frame 2 and cross beam 3 and longitudinal The main girder 1 and the cross girder 3 are plugged together by the connector 4, are connected to each other, are independent, can be assembled and adjusted at will, have sufficient strength and rigidity, and are completely independent and interchangeable.

[0029] The longitudinal main girder 1 is a support member arranged longitudinally and symmetrically throughout the length, and the longitudinal main girder 1 is located on the inner sides of the wheels on both sides of the vehicle frame, and plays a main supporting role for the whole vehicle frame.

[0030] Such as Figure 5 As shown, the wheel beam frame 2 is composed of two bridges 21, two bridge subframes 22, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com