Heat-conducting battery box

A battery box and heat-conducting adhesive technology, which is applied in the use/maintenance of primary batteries, secondary batteries, battery pack components, etc., can solve the problems of poor thermal conductivity and easy dust falling, so as to increase the ability to resist external shocks and Heat dissipation effect, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

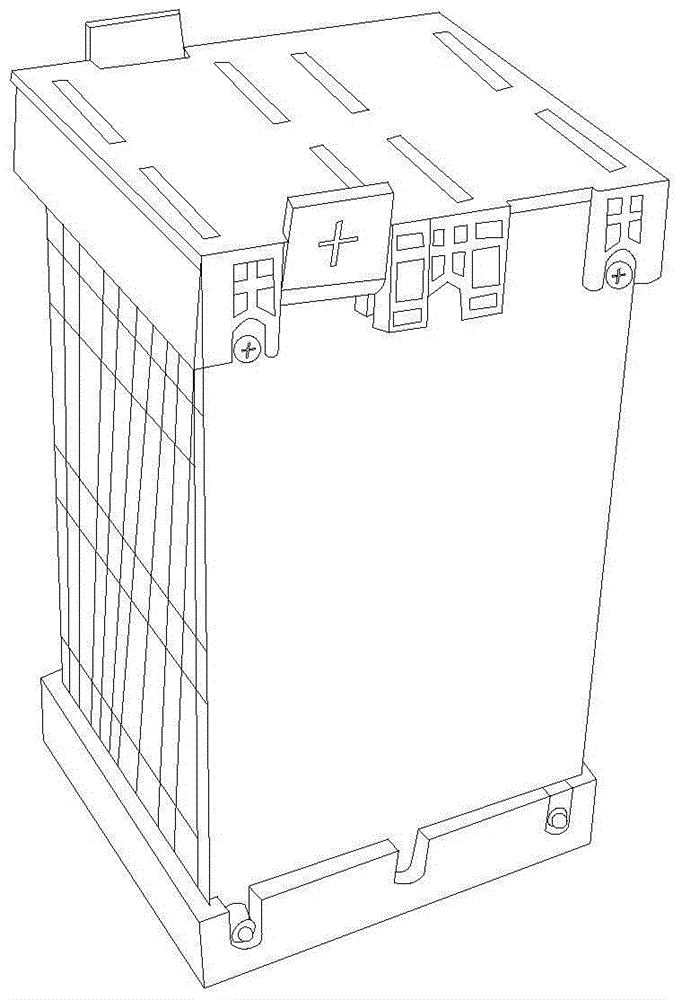

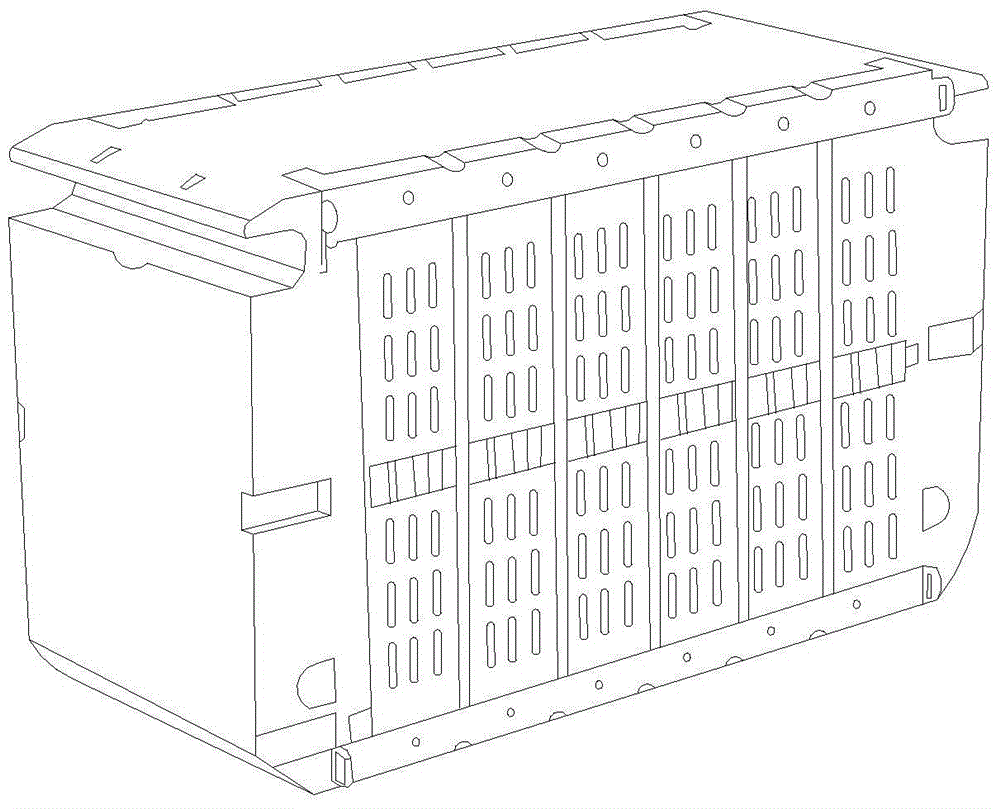

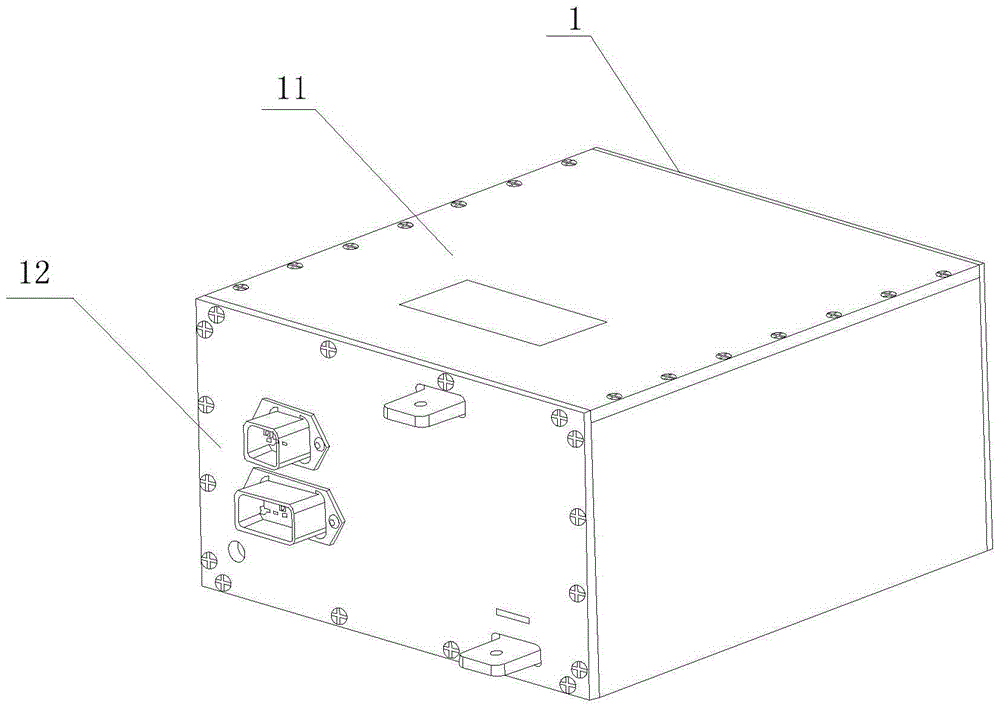

[0043] image 3 Schematic diagram of the structure of the thermally conductive battery box provided by the embodiment of the present invention; Figure 4 based on image 3 Schematic diagram of the structure of the bottom panel of the thermally conductive battery box shown; Figure 5 based on image 3 The schematic diagram of the internal structure of the thermally conductive battery box shown; Image 6 based on image 3 The schematic diagram of the structure of the heat conducting plate of the heat conducting battery box shown; Figure 7 based on Figure 5 A partial enlarged view of the thermally conductive battery box shown; Figure 3-7 As shown, the heat-conducting battery box provided in this embodiment includes a battery box body 1, a plurality of rows of heat-conducting plates 2 are arranged inside the battery box body 1, and batteries 5 are arranged on the heat-conducting plates 2. One, can make the both sides of electric core 5 be close to heat conduction plate 2...

Embodiment 2

[0059] The heat-conducting battery box provided in this embodiment includes a battery box body 1, a plurality of rows of heat-conducting plates 2 are arranged inside the battery box body 1, and batteries 5 are arranged on the heat-conducting plates 2. Since there are multiple heat-conducting plates 2 and batteries 5, it can be Make both sides of the battery cell 5 close to the heat conducting plate 2, so as to improve the heat dissipation efficiency of the battery cell 5;

[0060] The battery box body 1 is a fully enclosed box, which effectively prevents the entry of dust and other fine particles in the air, and also increases the box's ability to resist external shocks; at the same time, all the gaps in the battery box body 1 are filled with heat-conducting glue, so that The heat generated by the battery is dissipated in the fastest way;

[0061] The heat conduction plate 2 includes a separator 21 and a bottom plate 22. The bottom plate 22 is vertically arranged with the sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com