Device and method for detecting large-scale reproducible concrete cavity of steel pipe

A technology for recycled concrete and void detection, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve problems such as internal voids, detection, and impact on structural performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

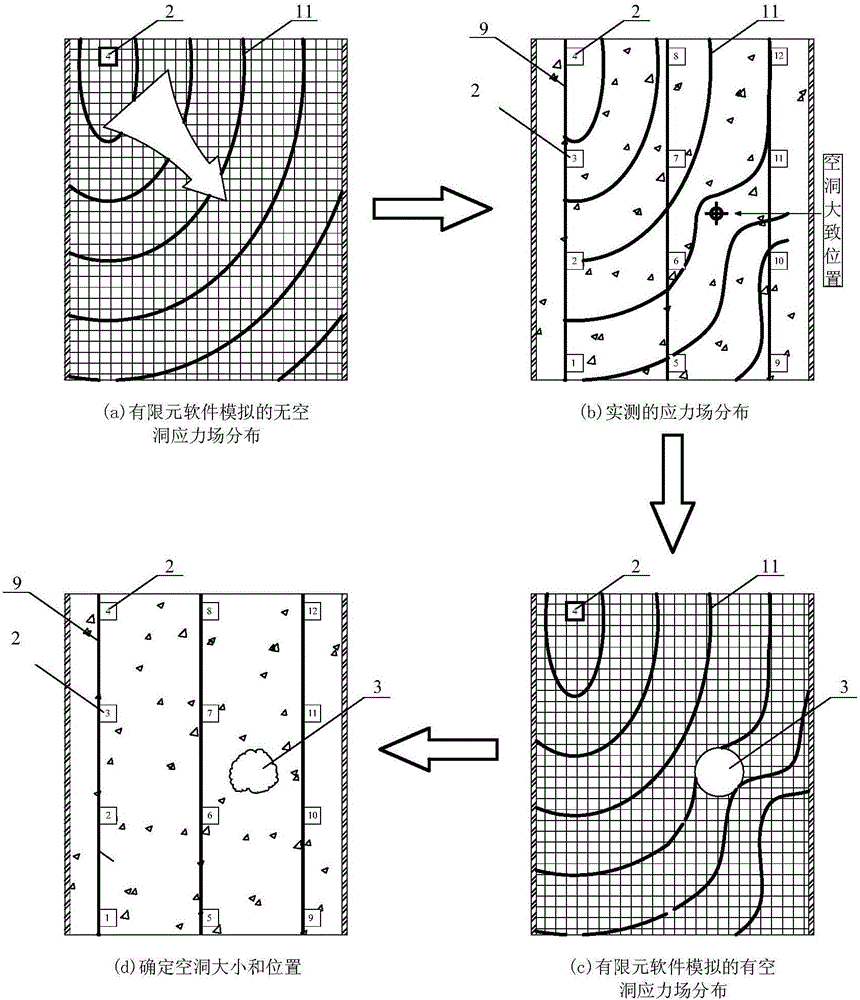

Method used

Image

Examples

Embodiment

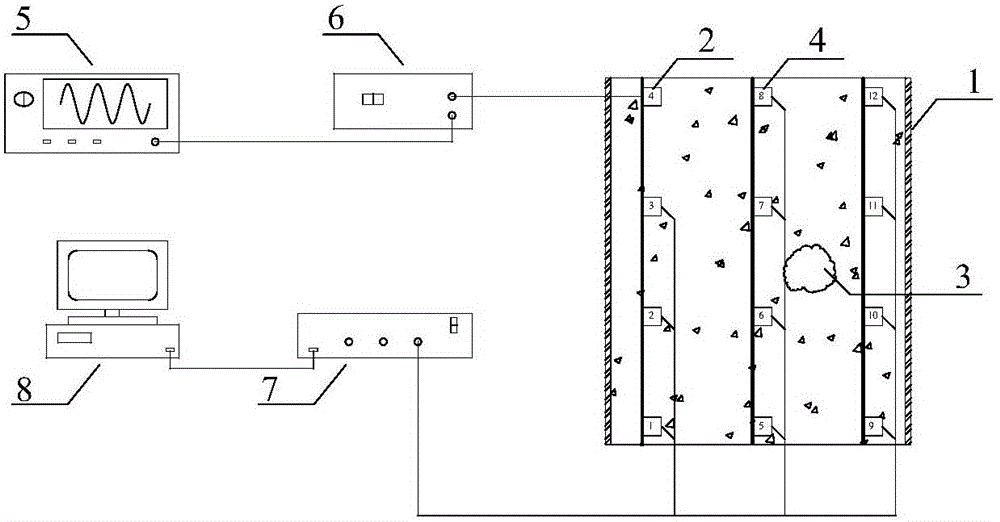

[0028] Such as figure 1 As shown, a steel pipe large-scale renewable concrete cavity detection device, including:

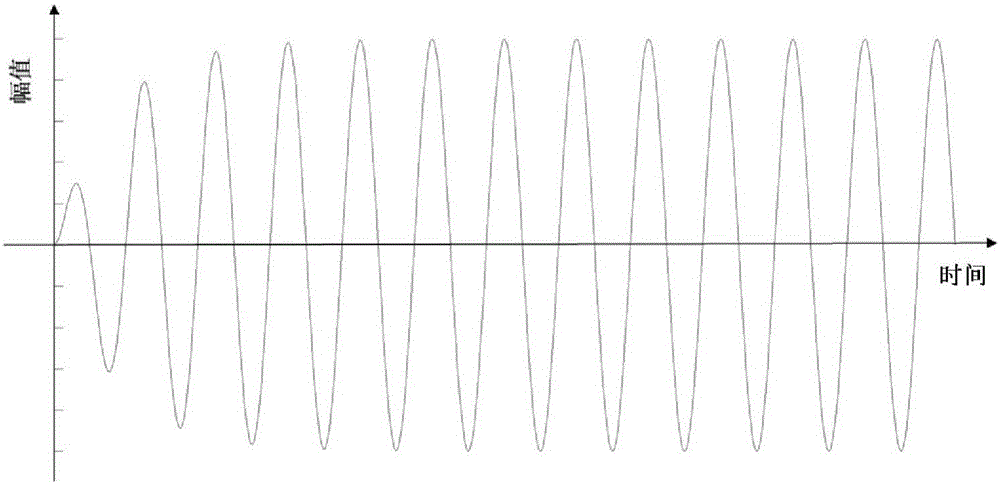

[0029] A sensor array, an arbitrary waveform function generator 5, a power amplifier 6, a data acquisition instrument 7, and a data analysis system 8 are arranged inside the large-scale renewable concrete member of the steel pipe (located on a two-dimensional plane) to form a network space detection area. The spacing of the array is 200-400mm, including the driving sensor 2 and the receiving sensor 4, the driving sensor 2 and the receiving sensor 4 are all made of piezoelectric intelligent aggregate, and the arbitrary waveform function generator 5 emits the set waveform function After the transmission signal is amplified by the power amplifier 6, it is transmitted to the driving sensor 2, and the signal is received by the receiving sensor 4 after passing through the large-scale renewable concrete medium of the steel pipe, and the received signal response is colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com