A hood type demister

A technology of mist eliminators and air caps, which is applied in the field of flue gas purification, can solve the problems that the structural design strength of the absorption tower cannot meet the load requirements of the electrostatic precipitator, the operation power consumption is large, and the construction cost is high, and the dust removal and mist removal effect is good. , The effect of good operation and low flushing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

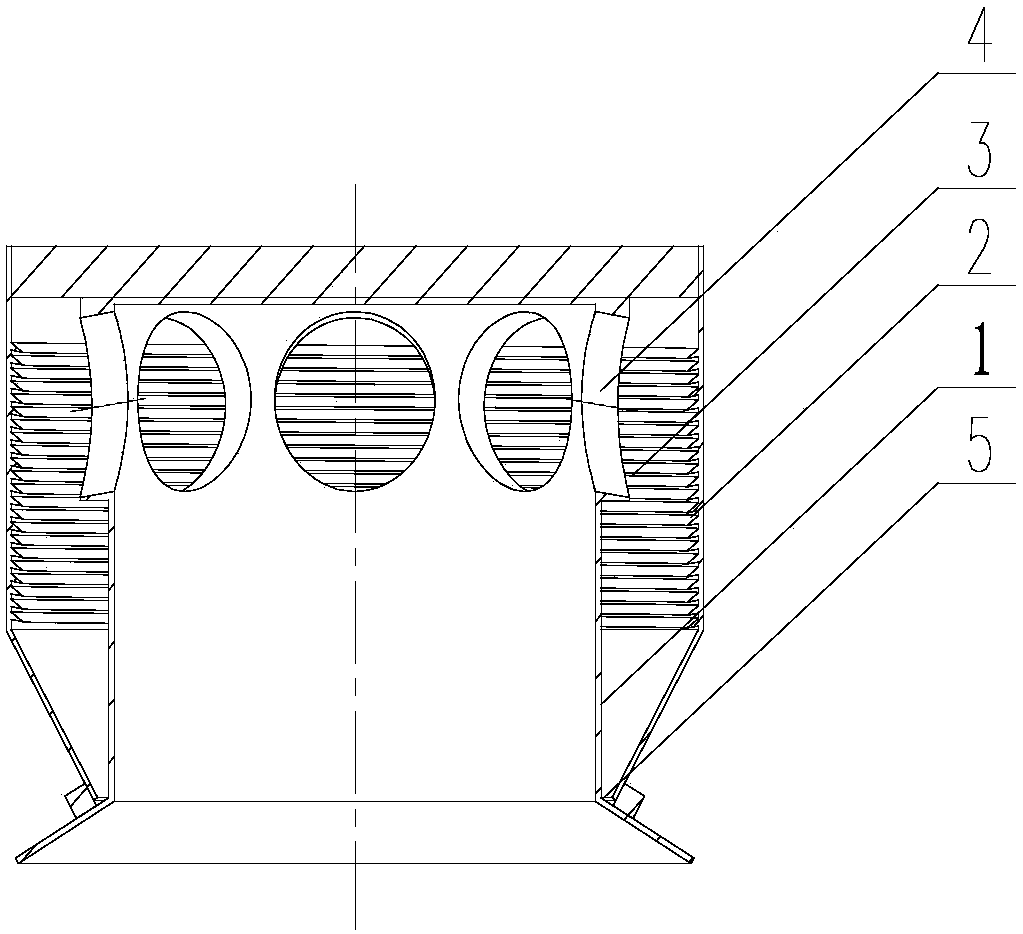

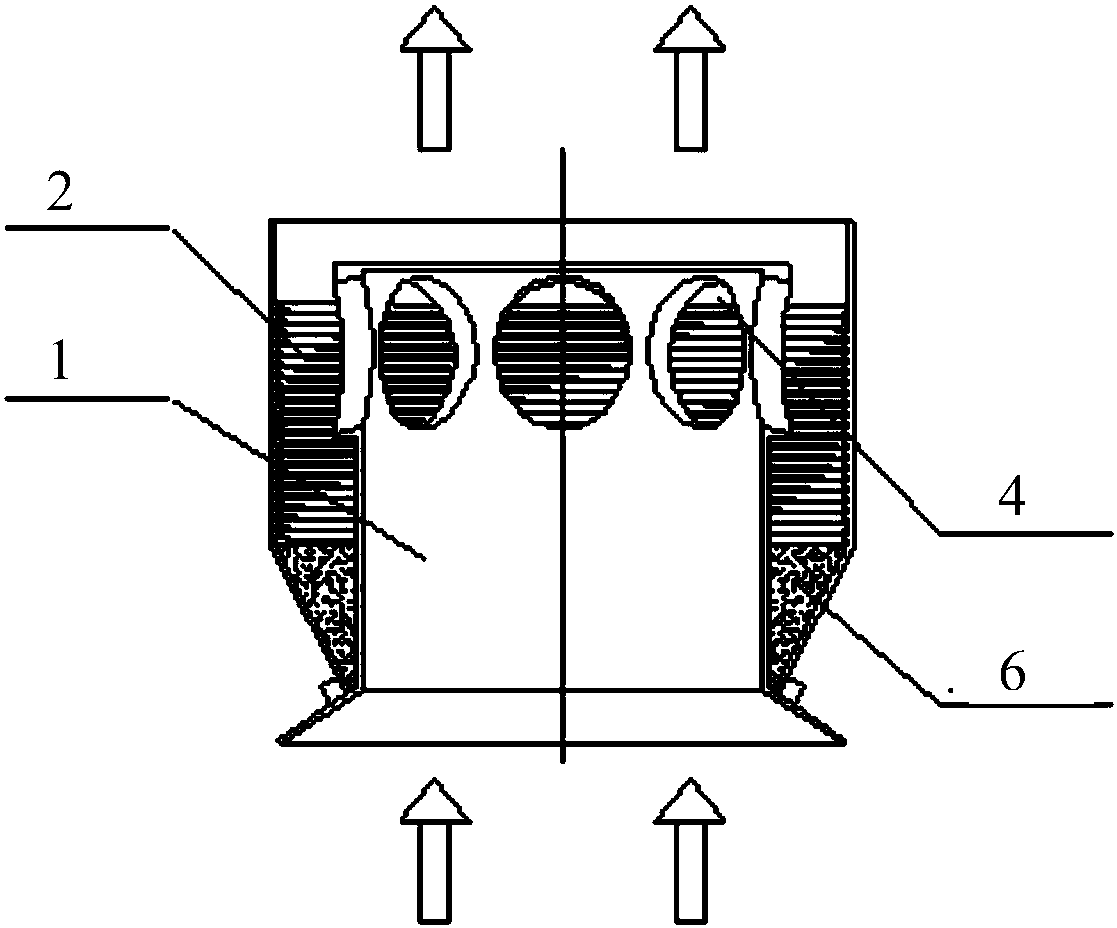

[0044] Such as figure 1 , figure 2 As shown, a hood type demister includes an inner guide cylinder 1, an outer guide cylinder 2, a spiral guide groove 3 and a guide hole 4. In order to create a flow state of high-speed rotating motion for the smoke passing through the device, a guide hole 4 is provided in the guide tube 1, and a smoke flow that moves obliquely downward at a high speed is formed through the guide hole 4; the guide The orifice 4 is a part on the guide tube in the dedusting and demisting device, and is a circular part with a certain thickness and height. A spiral guide groove 3 is provided on the inner wall of the outer guide cylinder 2 as required.

[0045] In order to discharge the collected liquid, a discharge ring hole 5 is set between the inner guide tube and the outer guide tube. The discharge ring hole is a smooth and even opening arranged at the lower part of the outer guide tube and tangent to the inner wall of the inner guide tube.

[0046] Specifi...

Embodiment 2

[0049] Embodiment 2, a hood-type demister is a flue gas flow-through part of a dedusting and demisting device, and is a vertically placed circular cylinder with a smooth inner wall and one end closed. Installed in the desulfurization absorption tower, the saturated flue gas containing a large number of mist droplets passes from bottom to top. Separation; wherein, the inner guide tube is placed vertically, and the guide holes are evenly distributed on the inner guide tube at a certain inclined angle; the outer guide tube is a circular tube with a spiral guide groove embedded in the inner wall .

[0050] Further, the determination of the diameter and height of the inner and outer guide tubes and the number of guide holes can be adjusted according to the outlet droplet control index that needs to be met.

[0051] Further, the diversion holes at the inclination angle of the inner diversion cylinder meet the actual speed of the gas rotation after diversion ≥ 8m / s.

[0052] The gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com