Egg-milk pulp essence and preparation method thereof

A custard flavor base material and technology of custard flavor base, applied in food ingredients as thickeners, food ingredients as odor improvers, food science, etc., can solve the problems of custard flavor stimulation, poor high temperature stability, etc. Realistic custard flavor, good viscosity and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

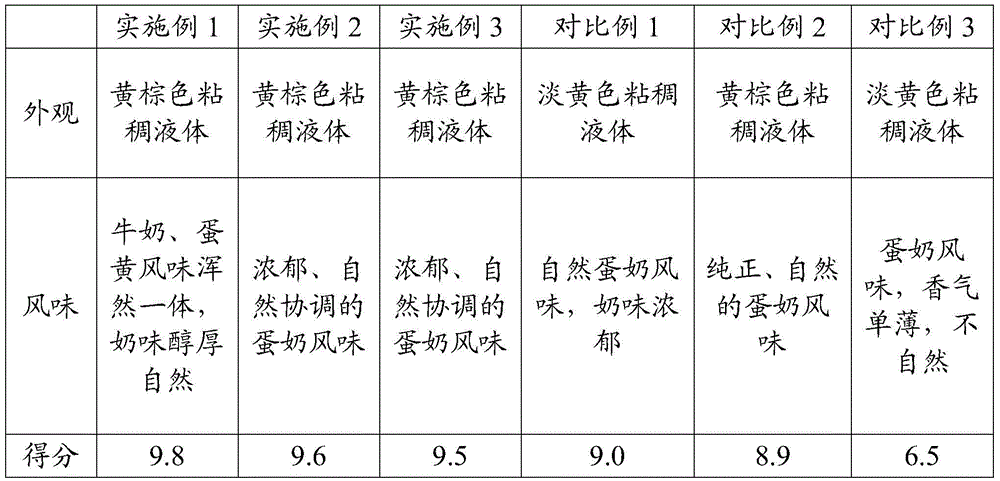

Examples

preparation example Construction

[0041] The preparation of the milk flavor essence base material used in the embodiment is as follows:

[0042] Milk flavor base material is prepared from reaction substrate and immobilized lipase, add 100U immobilized lipase SY-E100 per gram of reaction substrate;

[0043] The reaction substrate includes the following raw materials in weight percentage: 20% of anhydrous milk fat, 10% of δ-laurolactone, 3% of 95wt% ethanol solution, 6% of deionized water, and 61% of propylene glycol.

[0044] The preparation method comprises the following steps:

[0045] Heat the anhydrous milk fat to 50°C, after the anhydrous milk fat is completely dissolved, add lactone, 95wt% ethanol solution, deionized water and propylene glycol, stir for 15 minutes to mix evenly, add immobilized lipase SY-E100, and stir at a constant temperature of 50°C React for 48 hours, filter with a 100-mesh filter cloth, and the filtrate is the milk flavor base material.

[0046] The preparation of the custard essen...

Embodiment 1

[0051] A custard essence prepared from the following raw materials in percentage by weight:

[0052] Custard flavor base 12%, mono- and diglycerin oleate 0.3%, propylene glycol fatty acid ester 0.5%, milk flavor base material 20%, egg milk flavor base material 10%, sodium carboxymethylcellulose 0.3%, sucrose Fatty acid ester (HLB=15) 0.3%, water 56.6%.

[0053] The preparation method comprises the following steps:

[0054] 1) Weigh the custard base, mono- and diglycerin oleate, and propylene glycol fatty acid ester into a clean stainless steel tank according to the proportion, mix, stir and heat to 65-70°C to keep warm, and it becomes the oil phase;

[0055] 2) Weigh the milk flavor base material, egg milk flavor base material, water, sucrose fatty acid ester and thickener according to the proportion, mix, stir and heat to 65-70°C and keep it warm to form the water phase;

[0056] 3) While stirring, slowly pour the oil phase into the water phase, and then emulsify at 6000 rp...

Embodiment 2

[0058] A custard essence prepared from the following raw materials in percentage by weight:

[0059] Custard flavor base 11%, mono- and diglycerin oleate 0.3%, propylene glycol fatty acid ester 0.5%, milk flavor base material 17.5%, egg milk flavor base material 12.5%, sodium carboxymethylcellulose 0.4%, sucrose Fatty acid ester (HLB=15) 0.2%, water 57.6%.

[0060] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com