Electrolyte negative pressure rotary absorption device

A technology for absorbing device and electrolyte, applied in circuits, electrical components, battery pack components, etc., can solve the problem of insufficient absorption of electrolyte, and achieve the effects of not easy to deteriorate, good absorption effect, and large spray radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

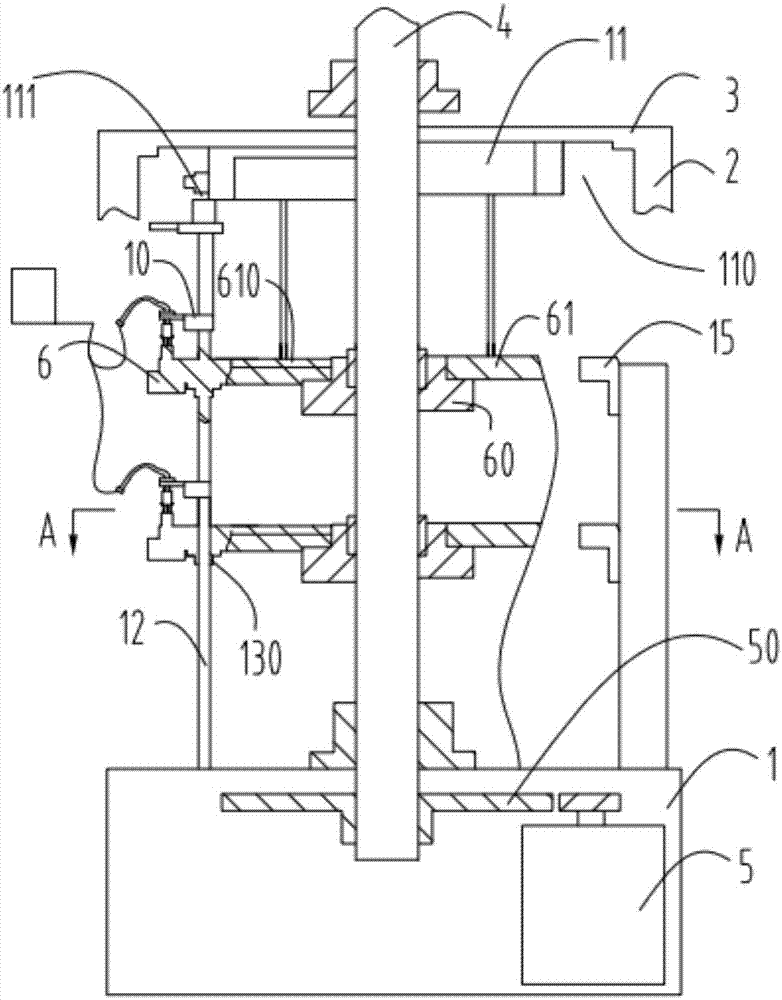

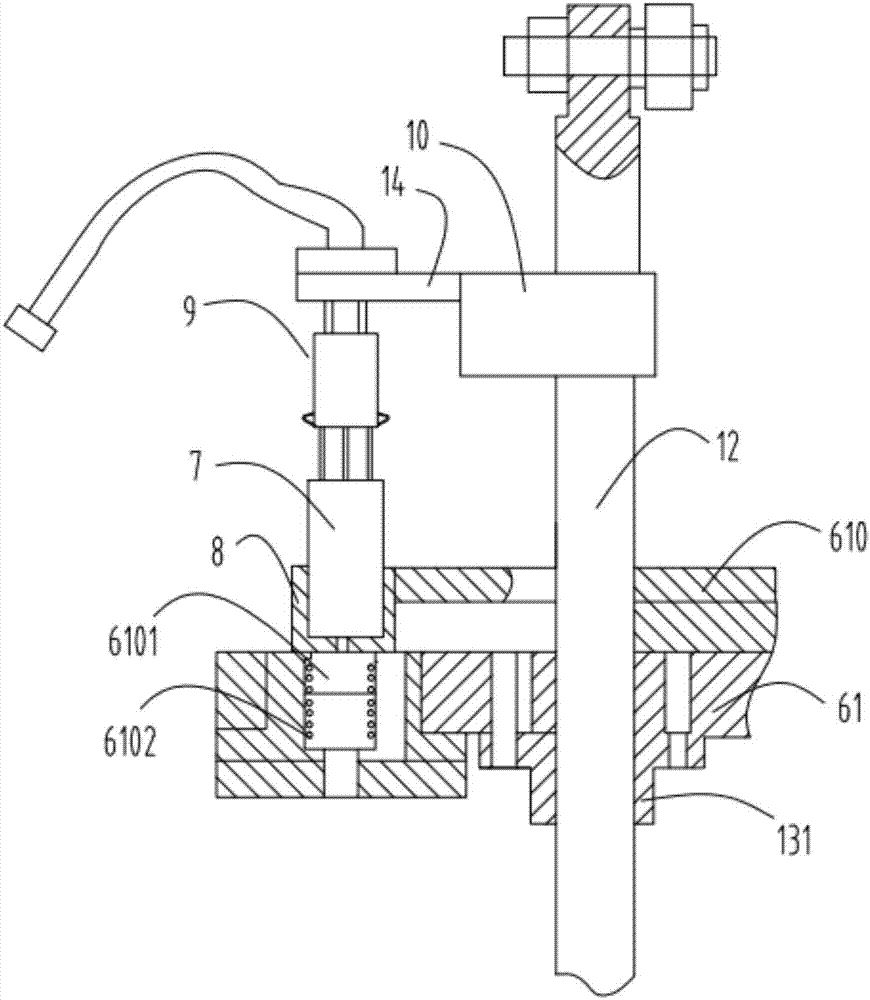

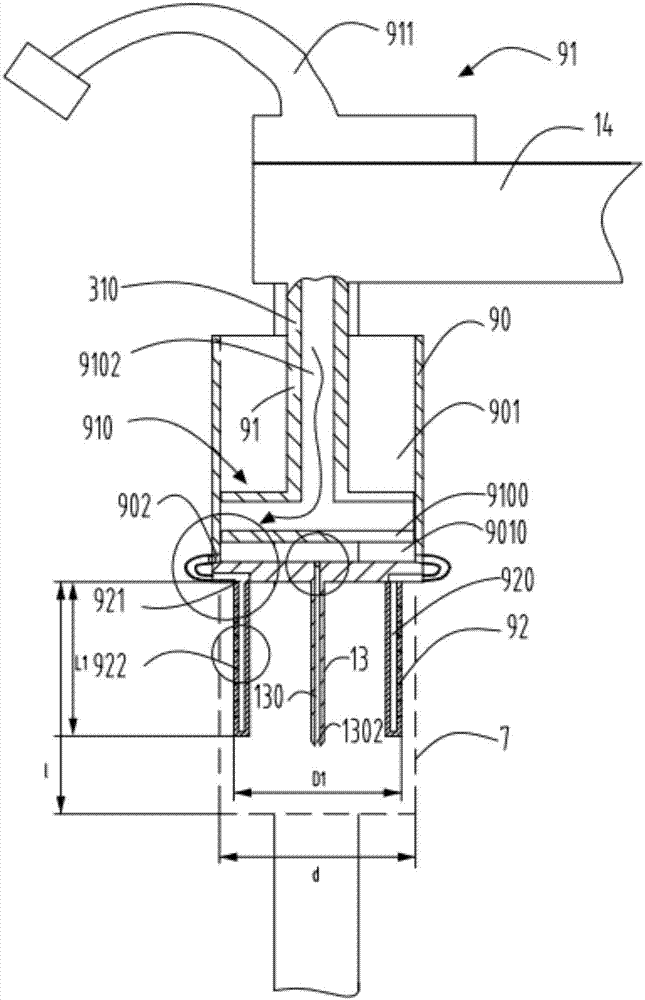

[0031] Such as figure 1 and figure 2As shown, an electrolyte negative pressure absorbing device includes a base 1, a column 2 fixed to the base, and a top plate 3 fixedly arranged on the top of the column, and a vertically installed driving shaft 4 is arranged on the base 1 and the top plate 3. The driving shaft 4 is driven by the main motor 5 to drive the gear 50 to transmit power. The driving shaft 4 is provided with a cup rotating mechanism 6, and the cup rotating mechanism 6 is evenly distributed with a plurality of cups 8 with batteries 7 installed along the circumferential direction; Including a negative pressure absorbing structure 9, the negative pressure absorbing mechanism 9 is used to inject electrolyte solution into the battery 7 after the battery 7 is in a negative pressure state; a lifting mechanism 10 that drives the negative pressure absorbing mechanism 9 to move up and down , the lifting mechanism 10 includes a first cam 11 fixed below the top plate 3, a cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com