Multichannel data collection method for pneumatic heating simulated test system

A simulation test system, data acquisition technology, applied in thermal analysis of materials, electrical program control, program control in sequence/logic controllers, etc. problem, to solve the problem of fast multi-channel data acquisition, high-speed data transmission capability, and shorten the control cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the drawings and examples.

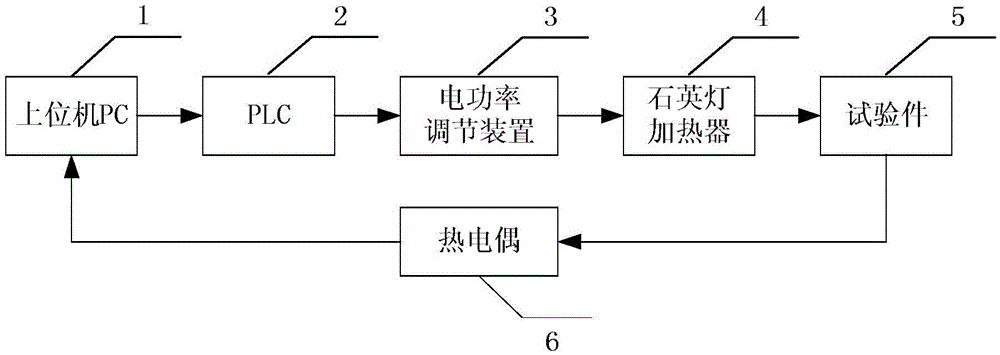

[0011] Application system structure reference of the embodiment of the present invention figure 1 , Consists of 1 host computer, 2 PLC, 3 electric power adjusting device, 4 quartz lamp heater, 5 test pieces and 6 thermocouples. The system collects test site data in real time through PLC, and outputs analog signals to control the output power in the electric power adjustment device; through the electric power adjustment device, it provides a controllable voltage to the quartz lamp heater to heat the test piece with thermal radiation.

[0012] The upper computer adopts Advantech industrial computer 610H, the main configuration is: Core E7400, memory 2GB, hard disk 160G.

[0013] The PLC adopts the B&RX20 series of B&R, which has the following characteristics: modular hardware; networking communication capability; with an interface for communication with HMI; with industrial comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com