Rotary drum type chemical fertilizer dryer

A drying device and fertilizer technology, applied in the direction of manure drying, drying gas arrangement, non-progressive dryer, etc., can solve the problems of drum furnace damage, uneven drying, large production volume, etc., and achieve simple and reasonable structural design and easy promotion Use, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

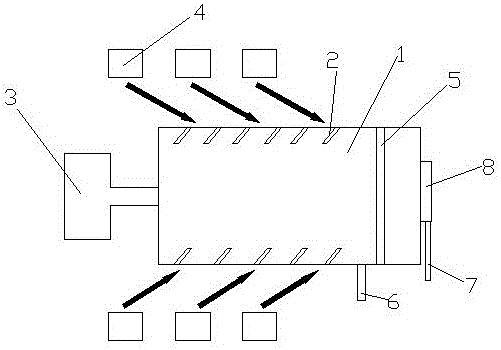

[0012] A rotary drum type fertilizer drying device, comprising a cylinder body 1, a spiral baffle 2, a motor 3, a fan 4, a filter screen 5, a discharge port 6, a water outlet 7, and a condenser 8. The cylinder body 1 is integrally connected with the The motor 3 is connected, the cylindrical body 1 is provided with the spiral baffle plate 2, a plurality of the fans 4 are arranged around the cylindrical body 1, and the lower part of the rear end of the cylindrical body 1 Set the outlet 6.

[0013] The cylinder body 1 is a cylinder body composed of multi-layer steel filter screens.

[0014] A multi-layer filter screen 5 is arranged at the rear end of the cylindrical body 1 .

[0015] The end of the cylinder body 1 is provided with a condenser 8 , and the lower end of the condenser 8 is connected to a water outlet 7 .

[0016] When the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com