Mining model of sub-stage rock-drilling and flat-bottom mining followed by filling

A technology of backfill mining and mine backfilling, which is applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve problems such as difficulty in understanding, and achieve the effects of improving efficiency, controlling sudden disasters, and simplifying ground pressure management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

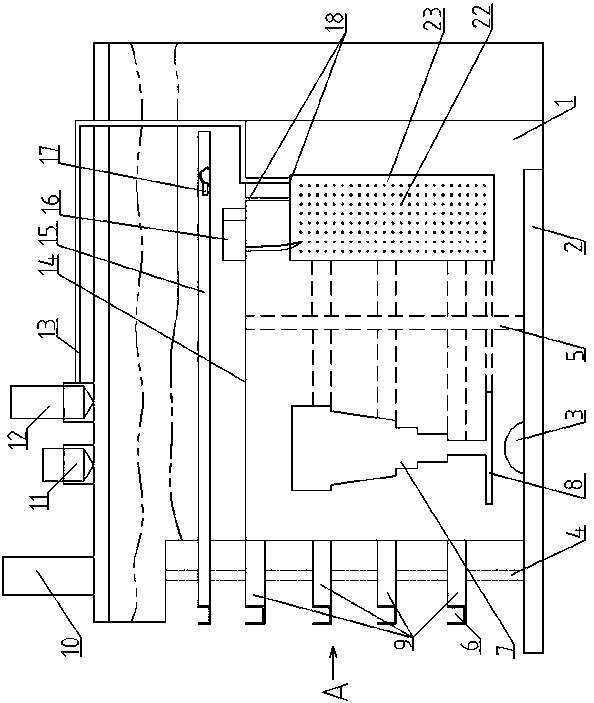

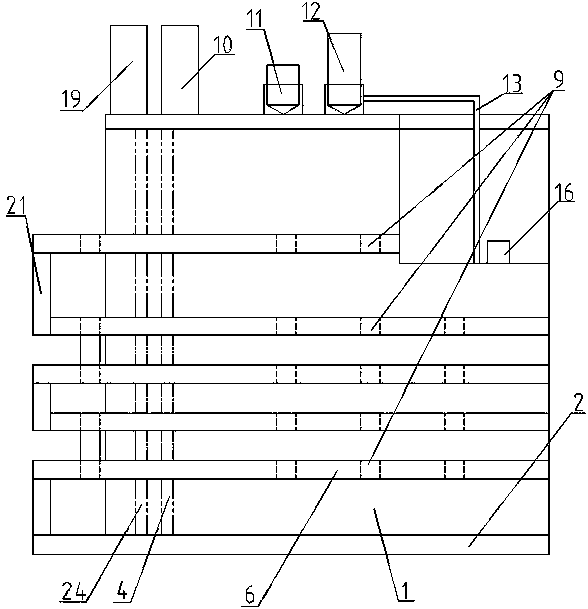

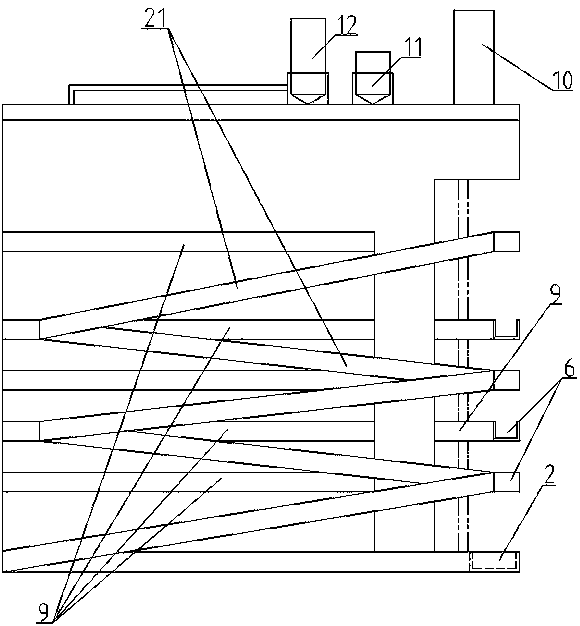

[0022] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0023] A kind of segmented rock drilling flat bottom mining model followed by filling mining, see the appendix figure 1 to attach image 3 , in the figure: model body 1, stage transportation roadway 2, mine entrance and exit intersection 3, main shaft 4, ventilation pedestrian patio 5, segmented transport roadway 6, ore layer being mined 7, bottom roadway 8, segmental rock drilling roadway 9 , main well machine room 10, cement silo 11, full tailings silo 12, filling pipeline 13, artificial platform 14, excavation roadway 15, main control element 16, rock drilling equipment 17, filling borehole 18, auxiliary well machine room 19, upper To the fan-shaped blast hole 20, the slope roadway 21, the photoelectric demonstration lamp 22, the mine room 23 to be filled, and the auxiliary shaft 24.

[0024] This embodiment consists of an aboveground part and an undergroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com