Structure and Construction Method of Hollow Slab Wide Bridge with Batch Transverse Stretch Strengthening Hinge Joints

A technology of transverse stretching and hollow slabs, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as deflection and reverse arching on wide bridges with hollow slabs, effective prestress cannot be guaranteed, and bonding force of joint surfaces cannot be guaranteed. , to achieve the effect of overcoming the transverse prestress tension and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

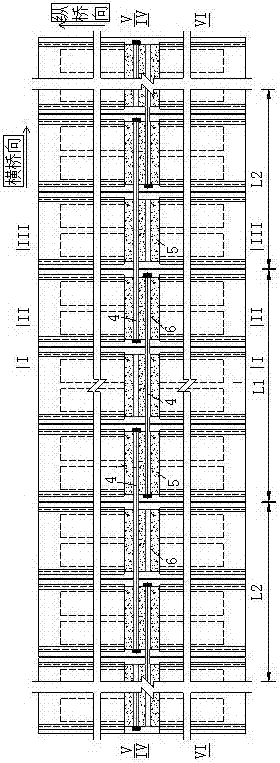

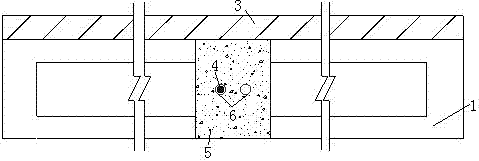

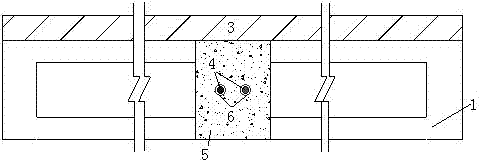

[0031] refer to Figure 1 to Figure 7

[0032] A wide bridge structure of hollow slabs reinforced with transverse stretching in batches, including prefabricated hollow slabs 1 arranged in parallel along the direction of the transverse bridge, and hinged joints 2 are arranged between two adjacent prefabricated hollow slabs, located between the prefabricated hollow slabs and A bridge deck pavement layer 3 is poured above the hinge joint, and prestressed steel tendons 4 are stretched transversely in batches inside the prefabricated hollow slab.

[0033] In this embodiment, when the span of the prefabricated hollow slab is 6m-10m, a diaphragm structure 5 is provided on the mid-span section of each prefabricated hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com