A 500m long rail train

A technology for long rail trains and rails, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of small space occupation and achieve the effects of convenient operation and maintenance, simple equipment structure and fast conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

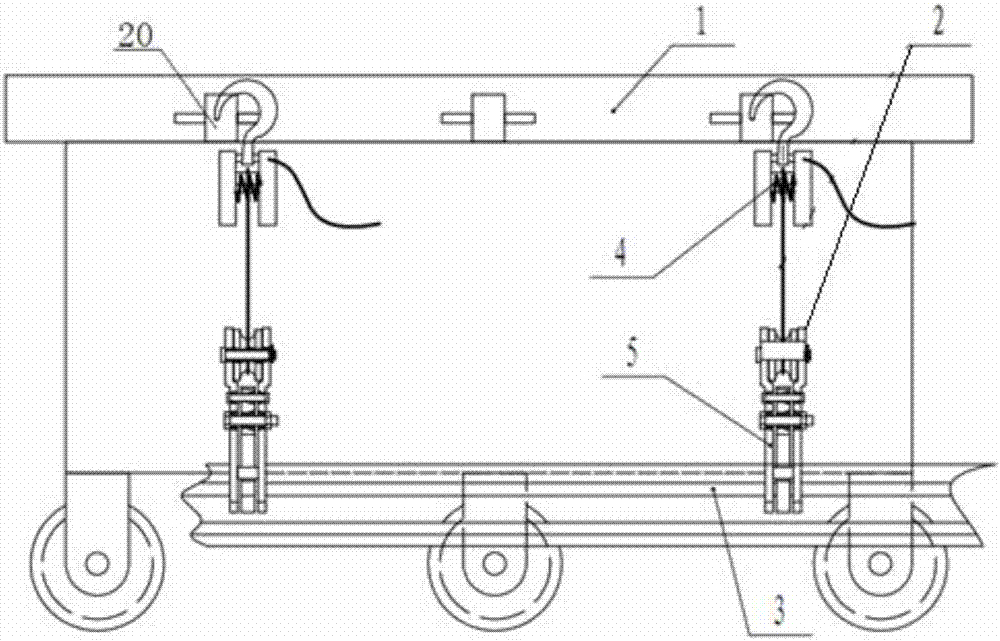

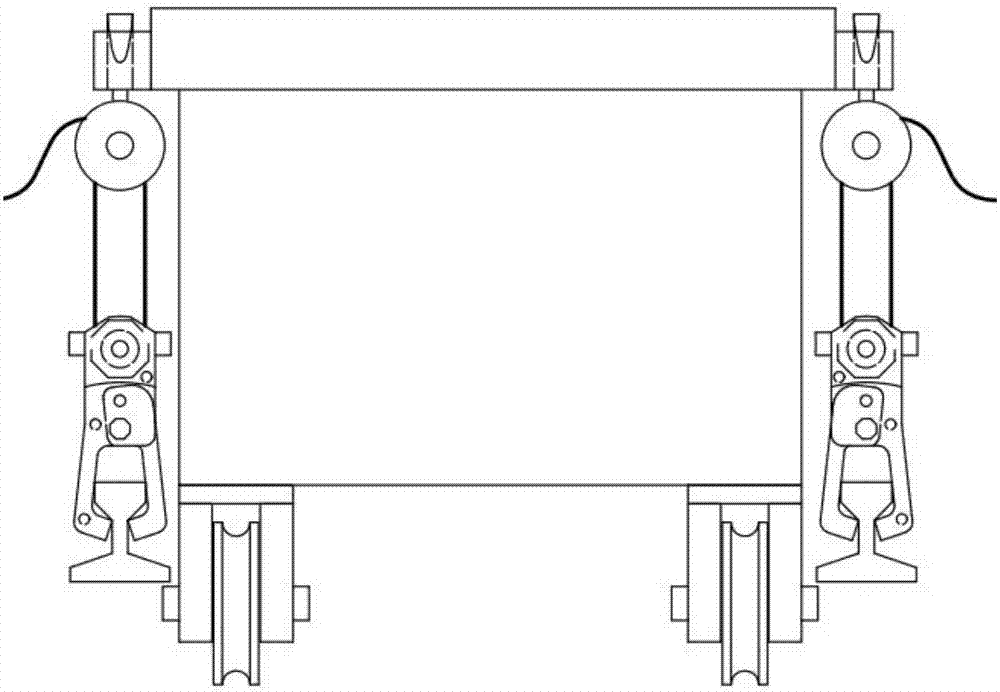

[0020] Embodiment 1: as Figure 1~Figure 5 As shown, a 500m long rail train includes a flatbed car 1, and each flatbed car is provided with four 2T chain hoist rail clip hooks for suspending the rail on the car sealing frame 20 on the longitudinal side of the flatbed car center, and transports a total of 148 500m long rails. 2T chain hoist rail clip hook, the 2T chain hoist rail clip hook 2 includes a chain hoist 4 and a clip hook 5 connected to the bottom end of the chain hoist 4, and the flatbed car adopts a railway N-type flatbed car. The four 2T chain hoist rail clamp hooks on the rails drive the hoist chains to lift the clamp hooks through the manual hoist, and hang the 500-meter-long rail on the flatbed truck to realize long-length rail transportation. The equipment has a simple structure and is easy to operate and maintain. , using the flatbed car that should be used for the paving frame, the purchase and manufacturing costs and maintenance costs are low, the conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com