Flat film layer spray orifice structure and ink-jet printer

A thin film layer and nozzle hole technology, applied in the field of inkjet printers, can solve problems such as clogging, alignment error, nozzle hole pollution, etc., and achieve the effect of not easy to damage, easy to manufacture, and strong damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be more clearly defined.

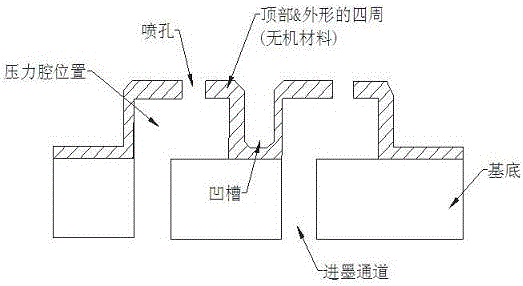

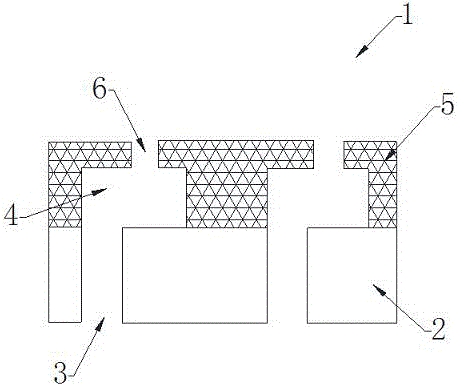

[0023] Such as image 3 As shown, a flat orifice film layer structure 1 includes a substrate 2. A plurality of ink inlet channels 3 are provided on the substrate 2, and the surface of the substrate 2 is flatly covered with a film layer 5. A number of pressure cavities 4 are arranged inside the film layer 5, and the pressure cavities 4 and the ink inlet channels 3 are in one-to-one correspondence and communicate with each other. The surface of the film layer 5 is also provided with a number of nozzle holes 6. The nozzle holes 6 Correspond to the pressure chamber 4 one by one and communicate with each other.

[0024] Such as Figure 4 As shown, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com