Absorbing core body

An absorbent core and absorbent core technology, applied in medical science, bandages, etc., can solve the problems of deformation of non-woven fabric coating, increase of absorbent resin, and inconvenience of carrying, so as to prevent gel blocking, increase air permeability, The effect of good wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

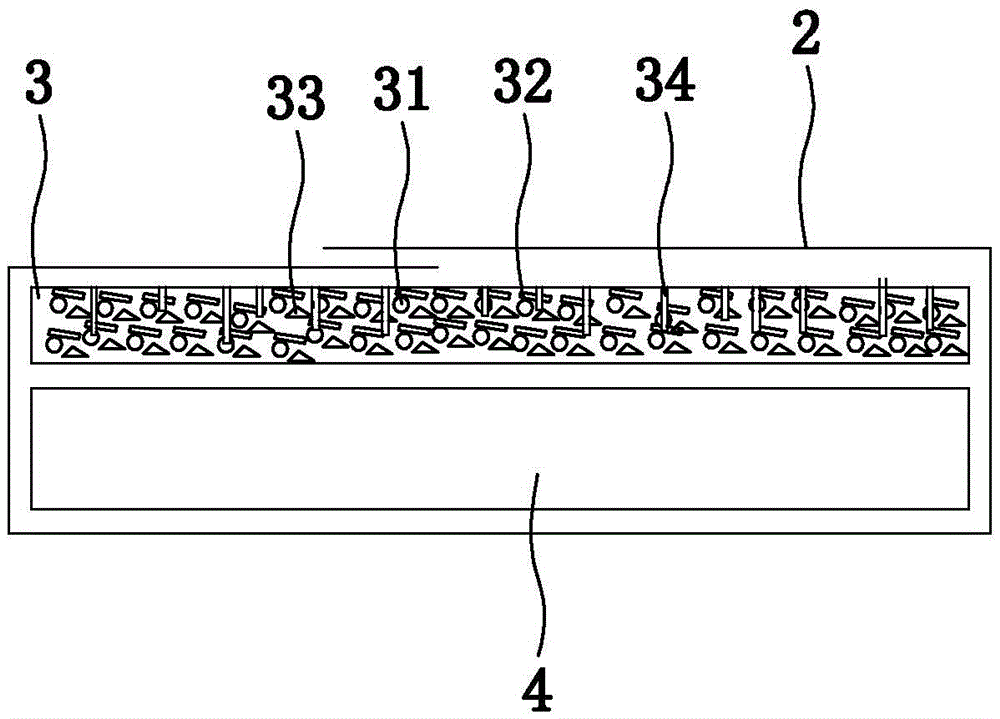

[0010] figure 1 As shown, an absorbent core body includes an absorbent core body 1 and a coating layer 2 with liquid-permeable properties. A layer of composite paper 3 is attached to the absorbent core body 1. The absorbent core body 1 is wrapped with the composite paper 3. Wrapped in the coating layer 2, the composite paper is formed by mixing 30 parts by weight of polymer water-absorbing resin particles 31, 50 parts by weight of non-woven fabric fragments 32, and 10 parts by weight of plastic film fragments 33. A plurality of non-penetrating holes 34 are provided in the thickness direction of the composite paper 3 . The length of the non-woven fabric fragment 32 is less than 5 mm and greater than 3 mm, and the length of the plastic film fragment 33 is less than 4 mm and greater than 2 mm.

[0011] The above-mentioned composite pap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com