Mechanical cake pressing machine

A cake press machine, mechanical technology, applied in the field of mechanical cake press, can solve the problems of laborious cake pressing, etc., to achieve the effect of ensuring molding rate, ensuring reliability, and reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

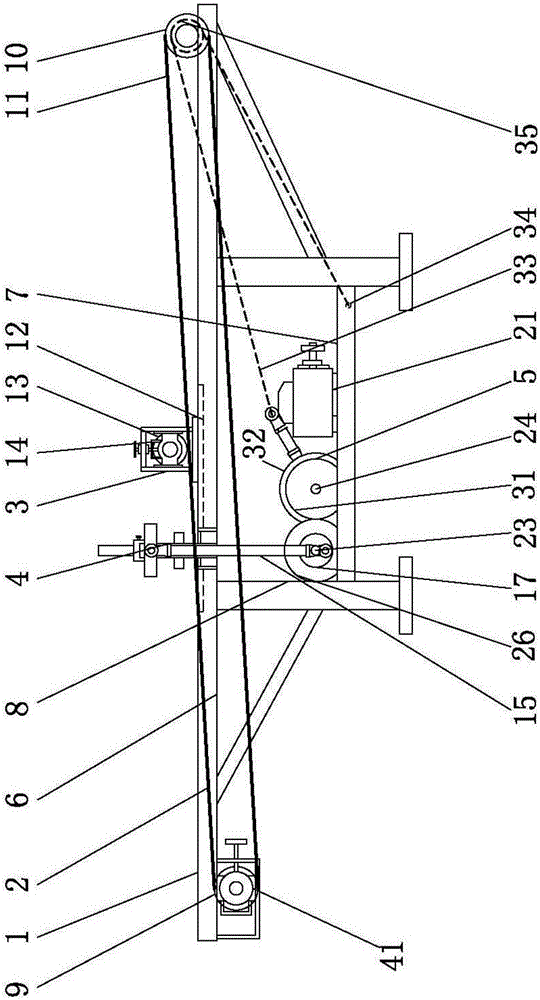

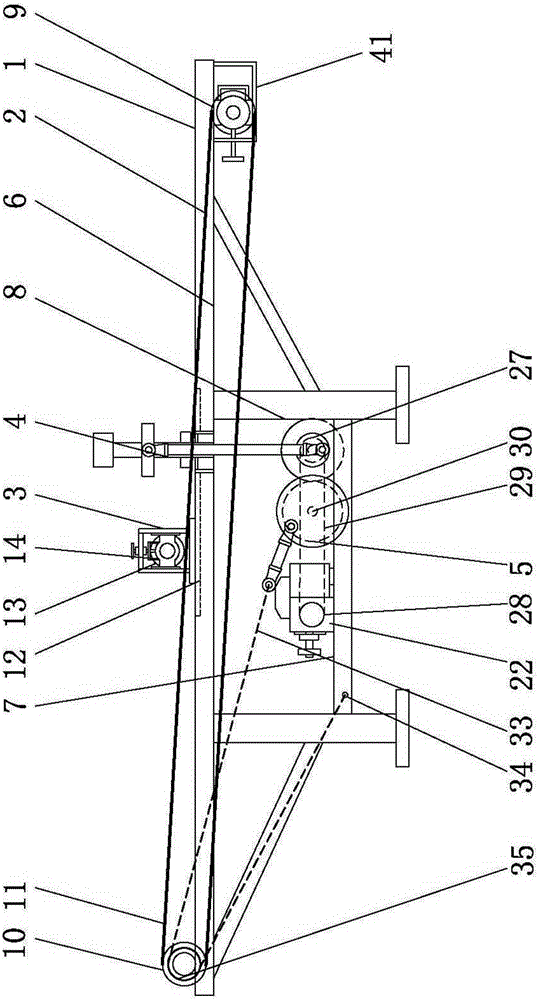

[0030] In order to solve the problem of low efficiency of manual cake pressing, such as figure 1 , figure 2 Shown: the present invention provides a mechanical cake press, including a support member 1, a conveyor belt device 2, a noodle pressing device 3, a cake pressing mechanism 4, and a transmission device 5;

[0031] Wherein, the support member 1 comprises an upper frame body 6, a lower frame body 7 and four columns 8; Arranged in parallel and installed on the lower part of the four columns 8;

[0032] The conveyor belt device 2 includes a first roller 9 installed at one end of the upper frame 6, a second roller 10 installed at the other end of the upper frame 6, and a conveyor belt 11 wrapped between the first roller 9 and the second roller 10;

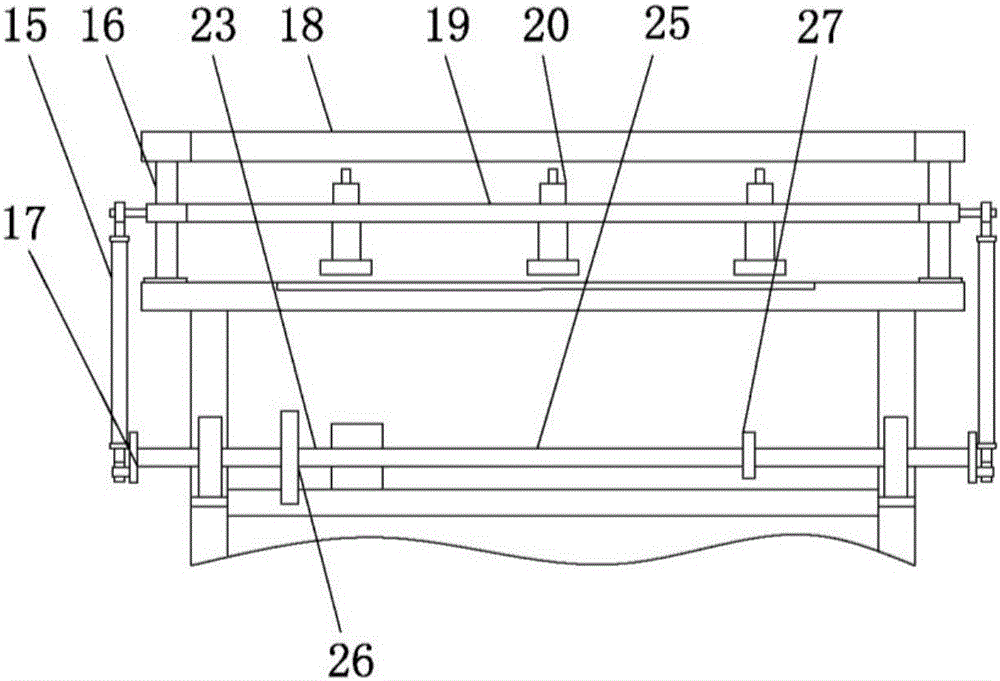

[0033] Noodle pressing device 3 and cake pressing mechanism 4 are successively arranged on the upper frame body 6 along the direction of travel of conveyor belt 11 and are all positioned above conveyor belt 11. Upper layer fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com