Cable placement frame

A technology for placing racks and cables, which is applied in the direction of pipe supports, electrical components, pipes/pipe joints/fittings, etc., which can solve the problems of large space occupation, unfavorable laying, easy to scatter cables, etc., and achieve simple structure, beautiful appearance and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

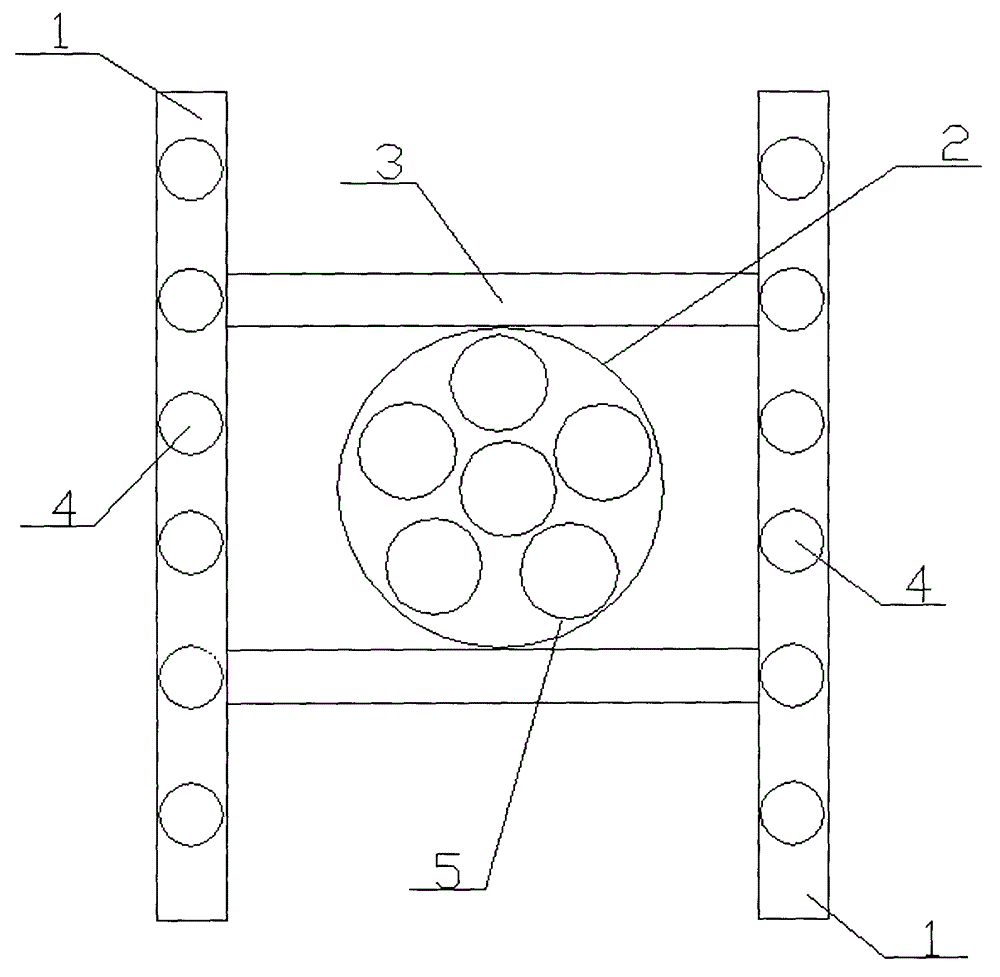

[0017] A cable placement frame provided in this embodiment has a structure such as figure 1 As shown, including the placement frame body 1 and the placement frame arranged on the placement frame body 1, the placement frame body 1 is two wooden poles arranged in parallel, six first threaded holes 4 are provided on the wooden pole, and the first screw thread The holes 4 are evenly distributed on the wooden pole, and there are also square through holes on the inner side of the wooden pole. The placement frame is composed of a fixed sleeve 2 and a fixed bracket 3 fixedly connected to the upper and lower ends of the fixed sleeve 2. The two ends of the fixed bracket 3 extend There are fixed projections, and the placement frame is inserted on the placement frame body 1 through the fixed projections at both ends of the fixed bracket 3. The fixed projections are provided with a second threaded hole that matches the first threaded hole 4 on the wooden pole. The sleeve 2 has a circular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com