Back pea gravel blow filling grouting construction method for single-shield hard rock roadheader after installing TBM pipe piece

A technology of a hard rock roadheader and a construction method, which is applied to shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of segment floating, large shrinkage rate, blocking shield, etc., and achieve the effect of avoiding pipe blockage and slurry return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

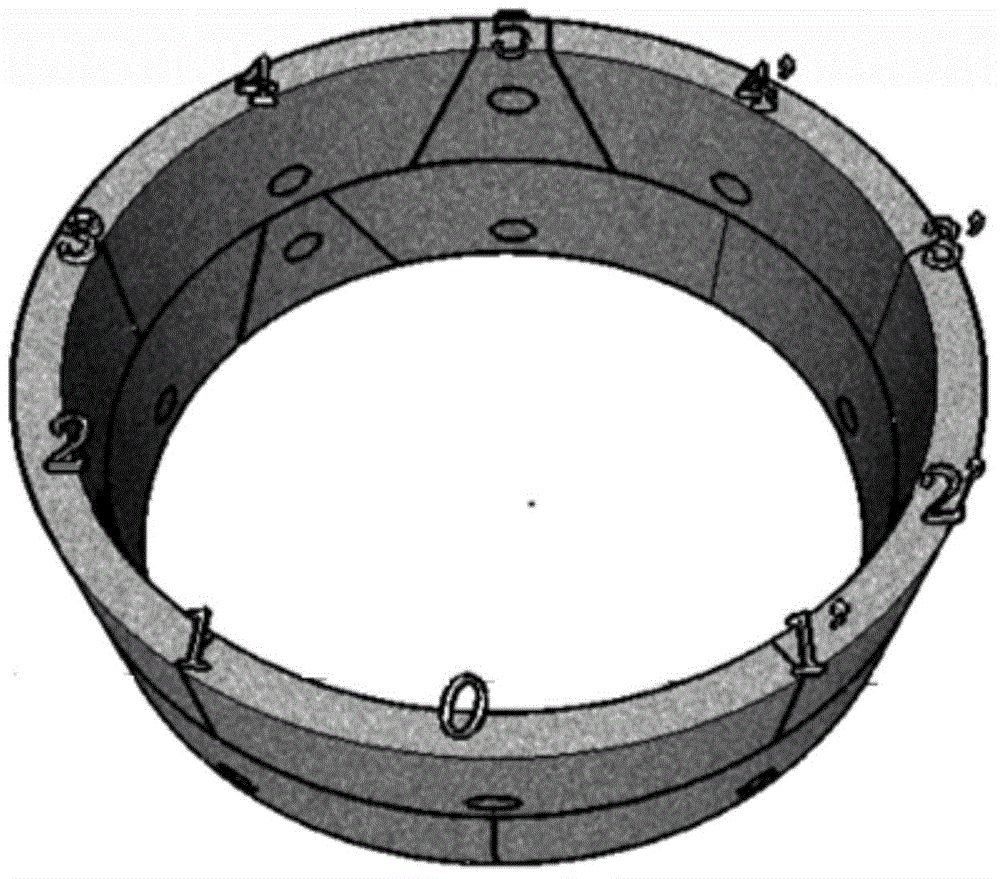

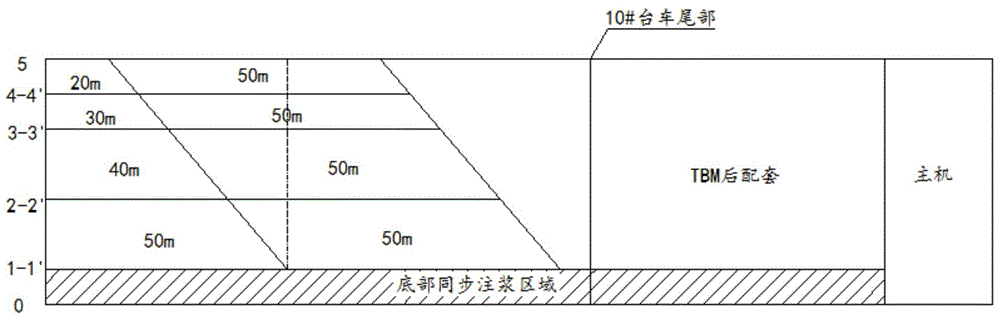

[0016] A construction method for dredging and grouting construction of pea-gravel behind the back of a single-shield hard rock tunneling machine TBM segment after installation, comprising the following steps:

[0017] 1. Do a good job of measurement acceptance and index detection for materials such as cement, pea gravel, and sand entering the site. The construction test mix ratio must be tested in the early stage, and the construction shall be carried out according to the construction mix ratio approved by the supervision engineer.

[0018] 2. Carry out performance tests on bean gravel dredging and grouting equipment, benches, etc., especially the air compressor and bean gravel jetting machine should be tested for wind pressure and air volume to meet the capacity of bean gravel dredging and filling; grouting pumps should be tested for water pressure , Check whether the status of the instrument is normal; the accuracy of the automatic control system of the high-speed pulping ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com