Electro-osmosis construction method of geogrid combined with grouting ultra-soft soil

A geogrid and ultra-soft soil technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as long construction period, geogrid unable to carry large-scale mechanical operations, and reinforcement effect difficult to meet time and design requirements , to achieve a reasonable moisture content, improve the status quo of disengagement, and reduce the effect of uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

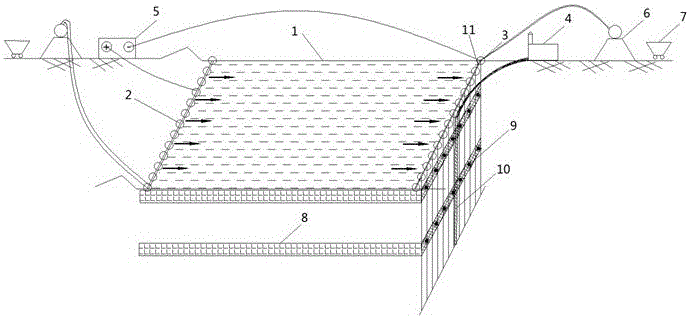

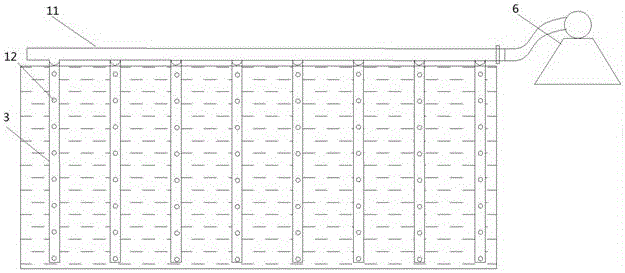

[0033] Such as figure 1 , 2 As shown, a geogrid joint grouting ultra-soft soil electroosmosis construction method, first, design the site area to be constructed according to the engineering plan, including:

[0034] (1) Use dredging engineering machinery to blow fill the silt soil at half the design height, use bamboo mesh frame geogrid 8 to reinforce the silt soil layer on the silt surface layer, and lay geotextile on the surface layer;

[0035] (2) Use dredging engineering machinery to blow fill the remaining half of the silt soil, and then use the bamboo mesh frame geogrid 8 to reinforce the silt soil layer on the silt surface layer and lay geotextiles on the surface layer;

[0036] (3) Arrange a certain number of grouted iron pipes as the anode 2 on one side of the ultra-soft soil site 1 according to the designed spacing, and arrange a certain number of grouted iron pipes as the cathode 3 on the opposite side according to the designed spacing, and the electrode spacing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com