Intelligent electric wire winding device

A wire winding device and electric power technology, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of waste of manpower, low intelligence, uneven winding, etc., to prevent excessive winding or Effect of prevention of vacancy, full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] as attached figure 1 to attach figure 2 shown

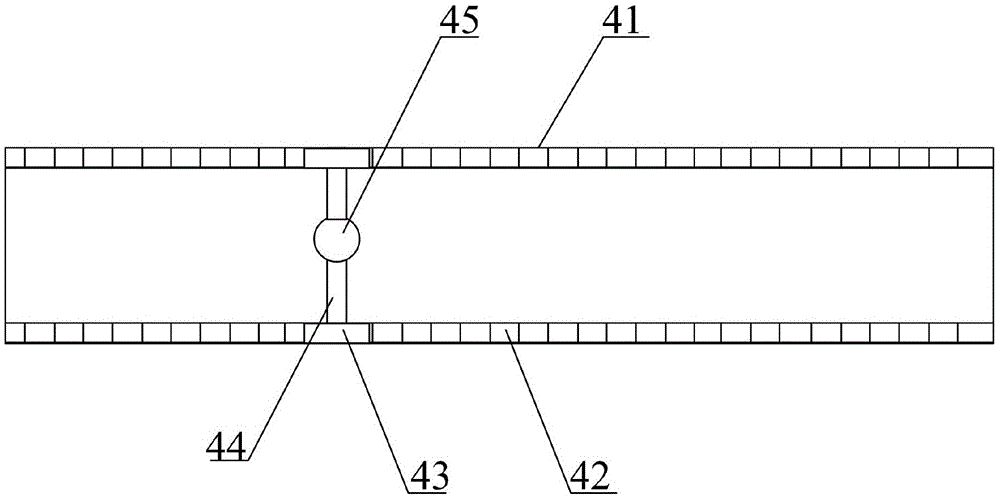

[0023] The invention provides an intelligent electric wire winding device, which includes a base 1, a baffle plate 2, a wire reel roller 3, a wire winder 4, a rotating shaft 5, a conveyor belt 6, a motor 7, a reducer 8, a controller 9 and rollers 10. The baffle plate 2 is fixedly installed on both sides of the upper part of the base 1 to support the wire reel roller 3; the wire winder 4 is arranged at the front end of the wire reel roller 3; the rotating shaft 5 It is coaxially connected with the reel turning roller 3, and is connected with the reducer 8 through the conveyor belt 6; the reducer 8 is connected with the motor 7; the controller 9 is installed on the upper part of the reducer 8; the wire winder 4 includes a mounting frame 41, a slide rail 42, a slider 43, a connector 44 and a wire hole 45, the slide rail 42 is installed on the mounting frame 41; a slide block 43 is installed in the slide rail; The connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com