A laminated glass writing board

A writing board and glass technology, applied in the field of glass deep processing and vertical home appliance panel decorative glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

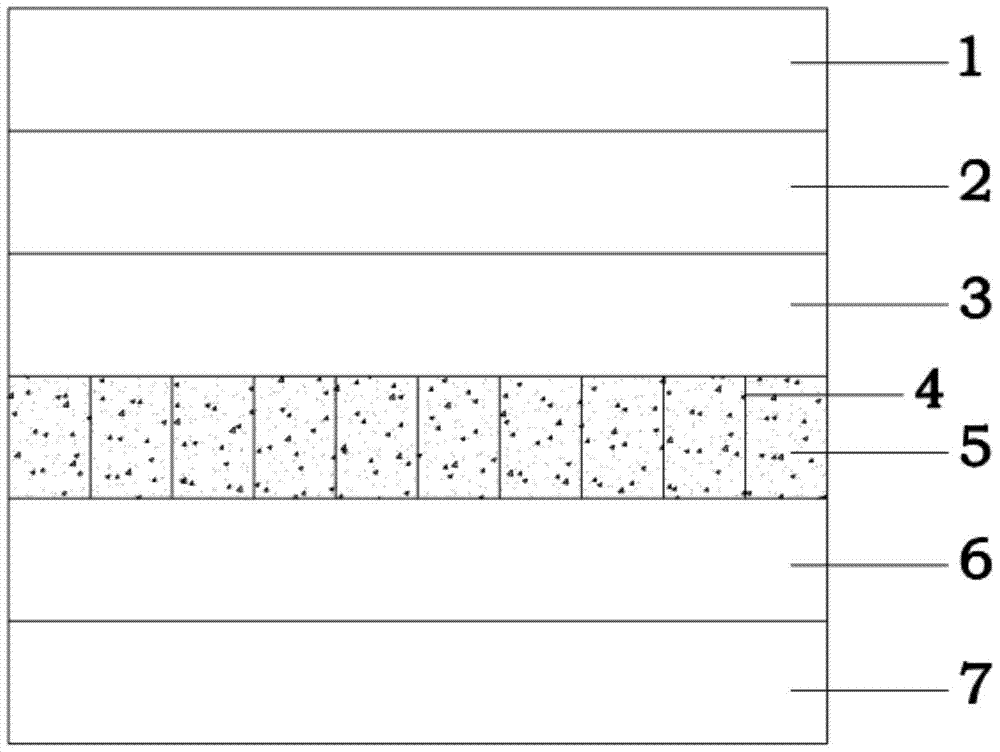

[0022] The laminated glass writing board is based on glass 1, and the upper surface of glass 1 is provided with an adhesive layer 2 of a UV adhesive layer. The lower surface is provided with a porous magnetic powder storage plate 4, and the inside of the porous magnetic powder storage plate 4 is provided with a magnetic powder 5. On the back of the porous magnetic powder storage plate 4, a lower electrically controlled magnetic soft plate 6 is arranged, and the lower electrically controlled magnetic soft plate 6 There is an illuminating panel 7 made of LEDs.

[0023] The UV adhesive layer is a mixture of varnishes coated on the glass 1 .

[0024] The upper electrically controlled magnetic plate 3 is a mixture of transparent PET material, magnetic powder and conductive layer covering the upper surface of the UV glue layer.

[0025] The porous magnetic powder storage plate 4 is a PET molding object installed on the upper electrically controlled magnetic plate 3 .

[0026] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com