Automatic control plant cultivation greenhouse

A technology for plants and greenhouses, applied in the field of automatic control of plant cultivation greenhouses, can solve the problems of high technical factors, lack of water for plants, complex seedling equipment, etc., and achieves the effect of saving electric energy resources, ensuring the planting environment, and meeting the needs of plant growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

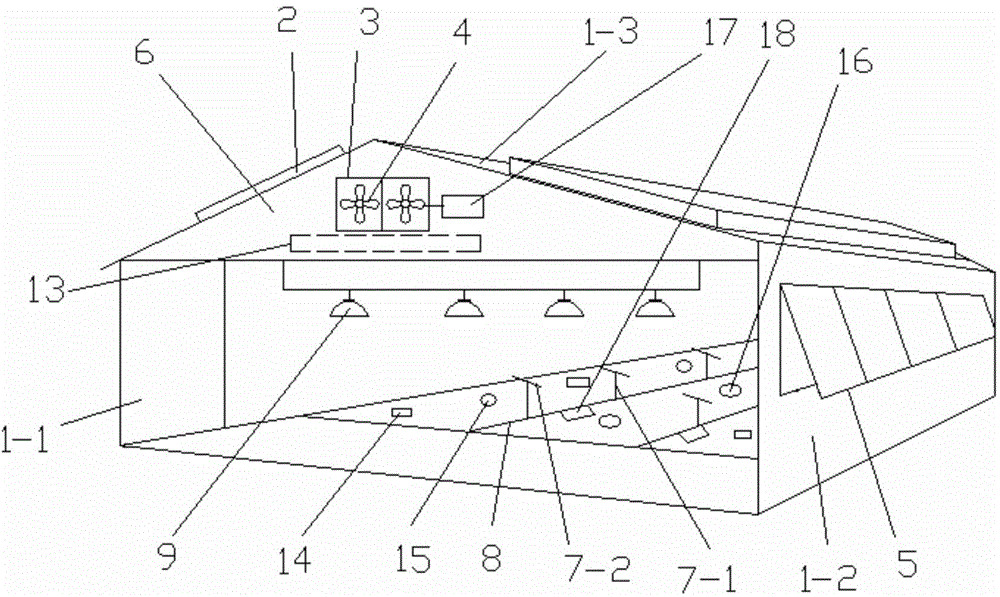

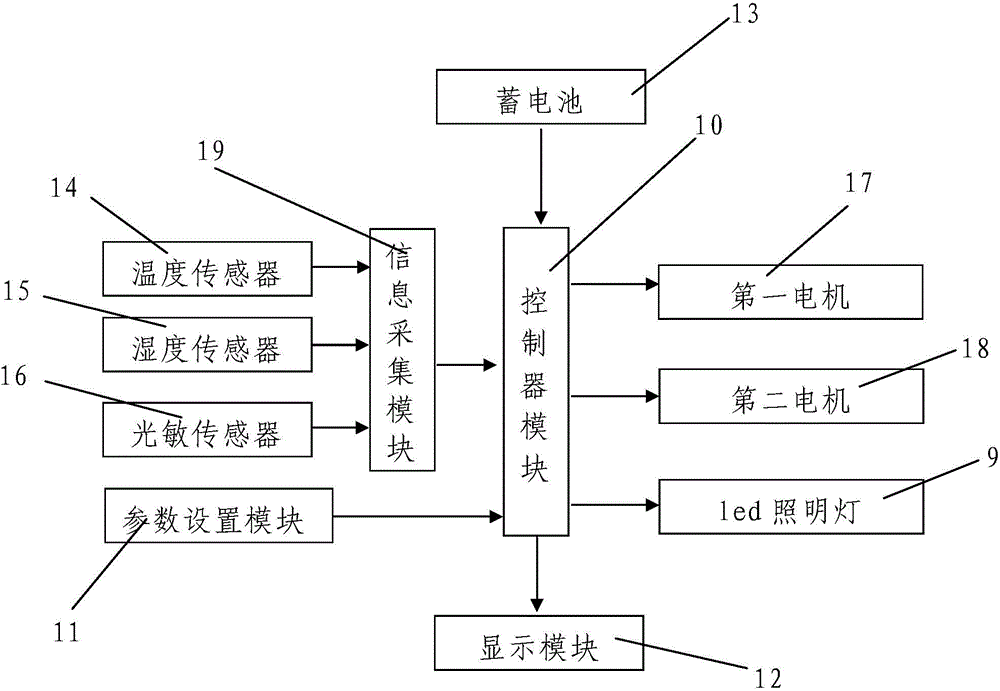

[0022] Such as figure 1 and figure 2 As shown, the plant cultivation greenhouse of the present invention includes a left support 1-1 and a right support 1-2 arranged in parallel on the ground, and the tops of the left support 1-1 and the right support 1-2 pass through the roof 1-3 connection, the roof 1-3 is provided with a solar panel 2, the ground between the left support 1-1 and the right support 1-2 is provided with a plurality of pipes 8 at intervals, and the plurality of pipes 8 are A plurality of branch pipes 7-1 are evenly spaced, and humidification nozzles 7-2 are installed at the ends of the branch pipes 7-1, electric windows 5 are provided on the right bracket 1-2, and a window 5 is provided under the roof 1-3. A connecting plate 6 is arranged between the left support 1-1 and the right support 1-2, and the connecting plate 6 is connected with the left support 1-1, the right support 1-2 and the ceiling 1-3, and the connecting plate 6 is provided with a skylight 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com