Method for operating a load connected to a motor vehicle electrical system

A technology for motor vehicles and on-board power grids, which is used in electrical components, regulating electrical variables, and output power conversion devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

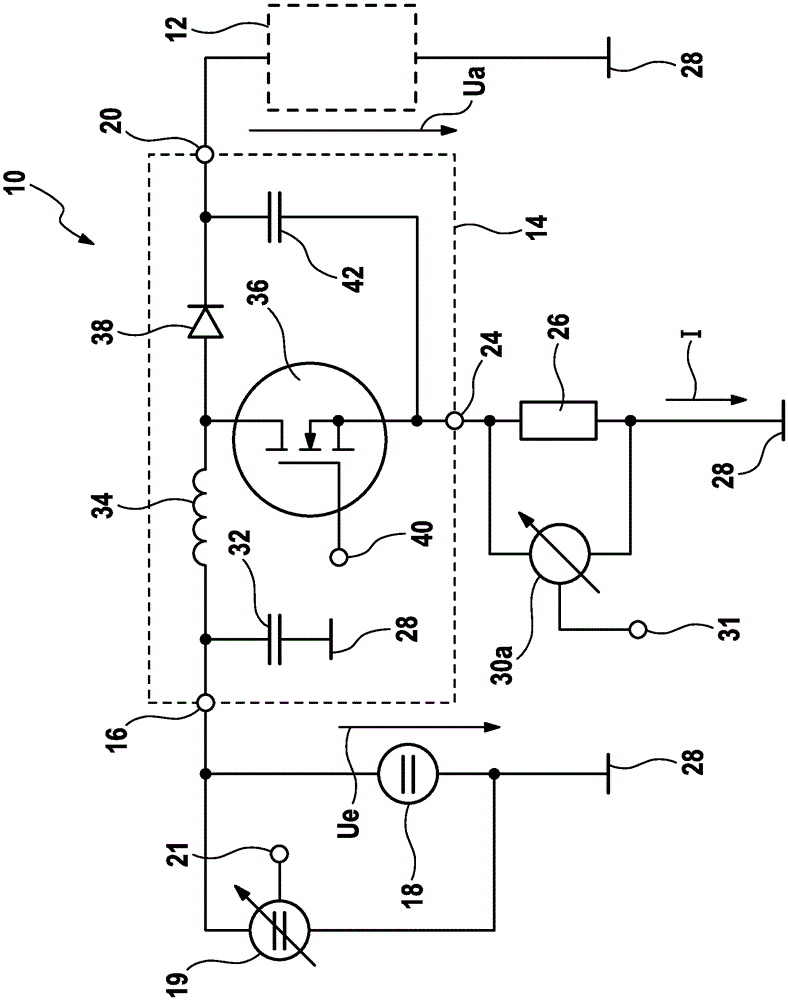

[0012] figure 1 Shown is a circuit 10 of a solenoid actuating device (not further shown) for actuating a load 12 , in particular a solenoid coil (not further shown), in particular a fuel injection valve (not shown) of an internal combustion engine (not shown) circuit diagram.

[0013] A DC voltage converter 14 (“current-controlled boost converter”, “boost converter”) is supplied with an input voltage Ue at an input 16 from a DC voltage source 18 and generates therefrom at an output 20 An output voltage Ua is at least temporarily higher than the input voltage Ue. The DC voltage source 18 is the on-board electrical system of the motor vehicle. The input voltage Ue is measured by means of a voltage measuring device 19 which sends its measurement signal to the terminal 21 .

[0014] Furthermore, the DC voltage converter 14 has a base terminal 24 in the lower region of the drawing, which is currently connected to a reference potential 28 via a current-measuring resistor 26 . Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com