Work-machine control system, work machine, hydraulic-shovel control system, and work-machine control method

A work machine and control system technology, which is applied to the control system of work machines, the control system of work machines, hydraulic excavators and the control fields of work machines, can solve problems such as increased operator burden, and achieve the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Modes (embodiments) for carrying out the present invention will be described in detail with reference to the drawings.

[0043]

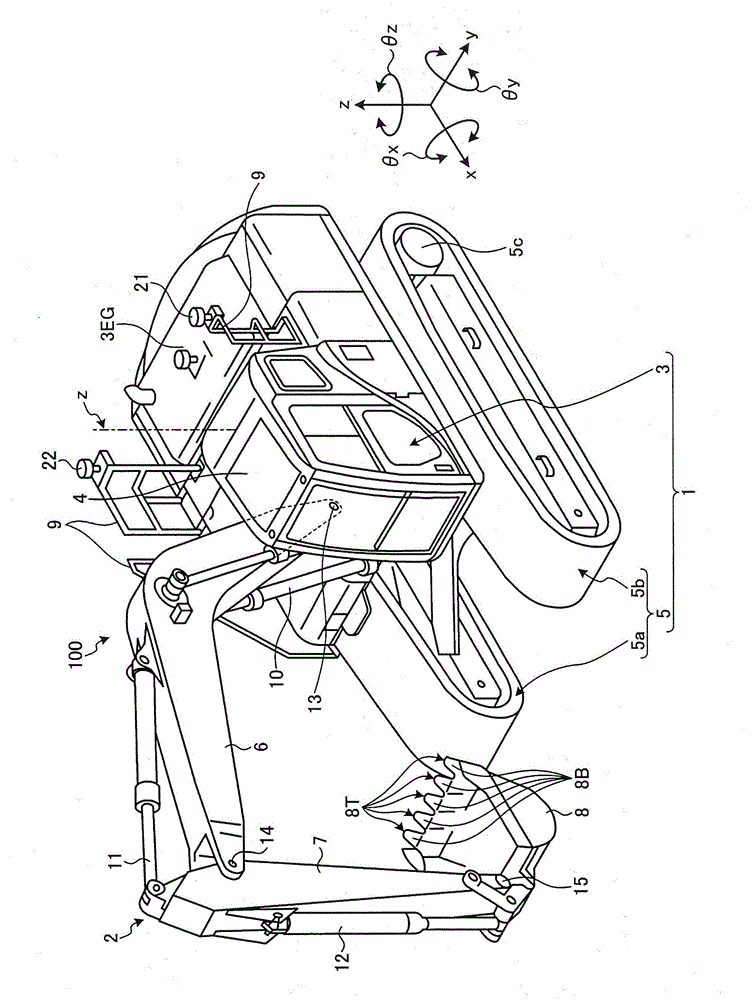

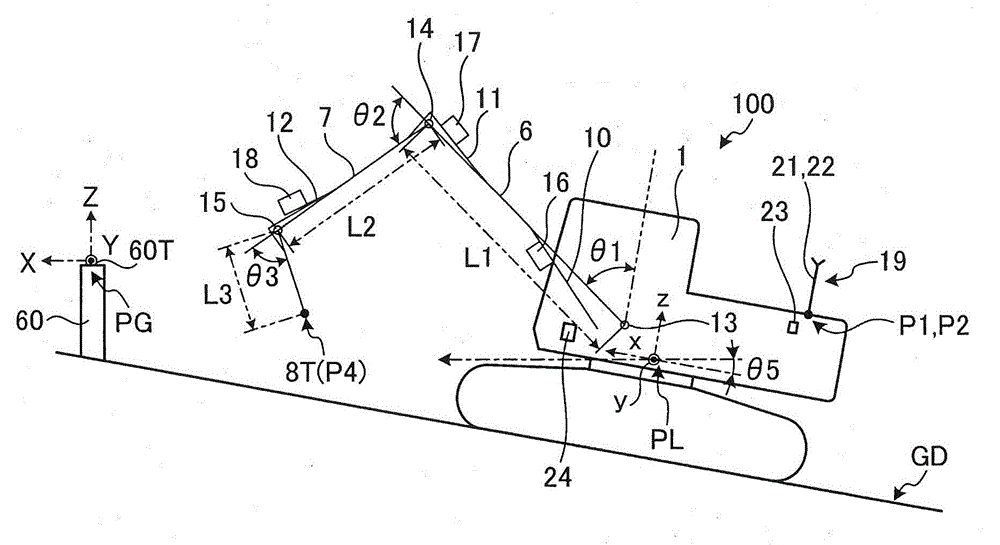

[0044] figure 1 It is a perspective view of the working machine of the embodiment. figure 2 It is a block diagram showing the configuration of the hydraulic system 300 and the control system 200 of the hydraulic excavator 100 . A hydraulic excavator 100 as a working machine has a vehicle body 1 and a work implement 2 as a main body. The vehicle body 1 has an upper revolving body 3 as a revolving body and a traveling device 5 as a traveling body. The revolving super structure 3 accommodates devices such as an engine and a hydraulic pump as a power generating device inside the machine room 3EG. The machine room 3EG is disposed on one end side of the upper revolving structure 3 .

[0045] In the embodiment, the hydraulic excavator 100 uses an internal combustion engine such as a diesel engine as an engine as a power generation device, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com