A self-dust-proof structure of an optical fiber connector

A technology of optical fiber connector and dust-proof structure, which is applied in the coupling of optical waveguide and other directions, and can solve problems such as inability to guarantee the docking effect and pollution of optical fiber pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

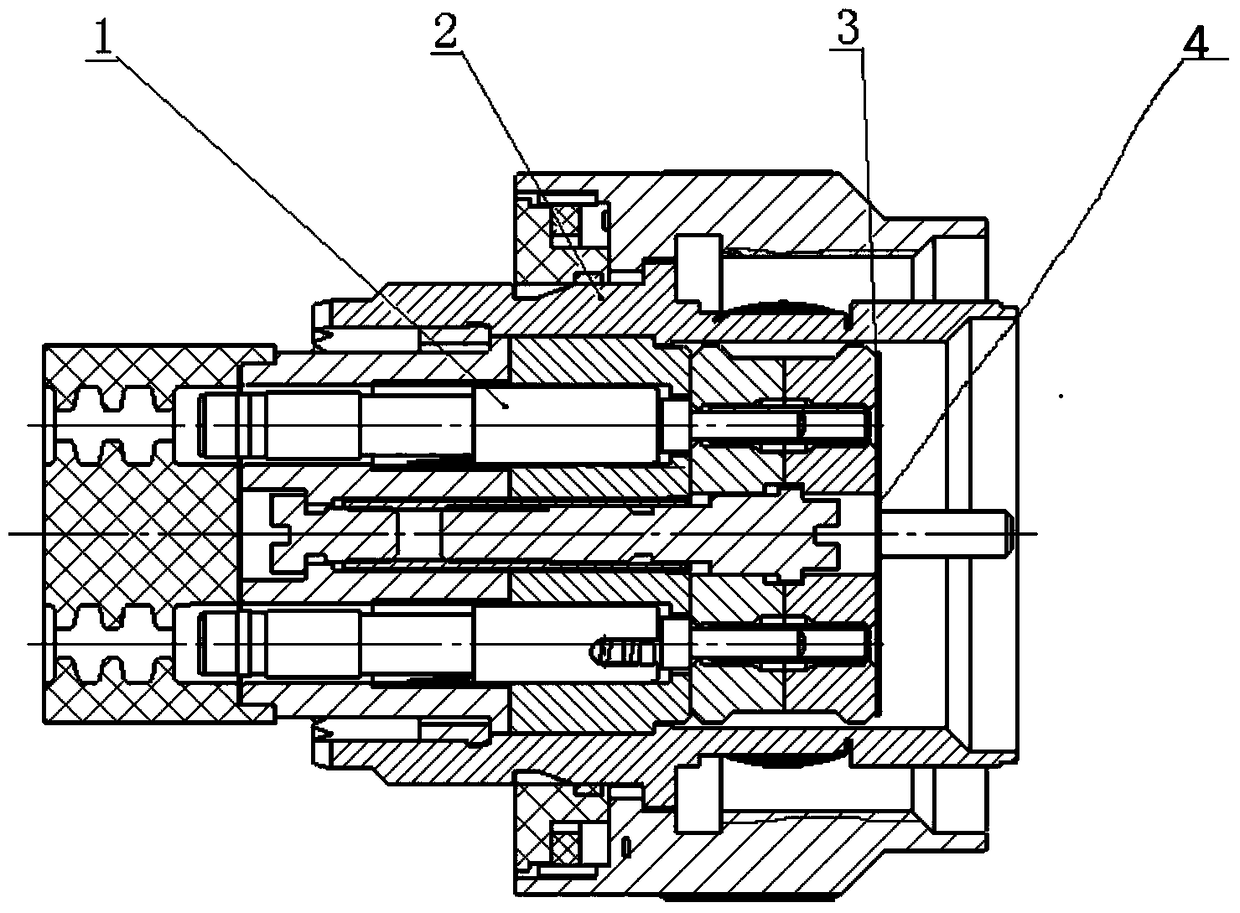

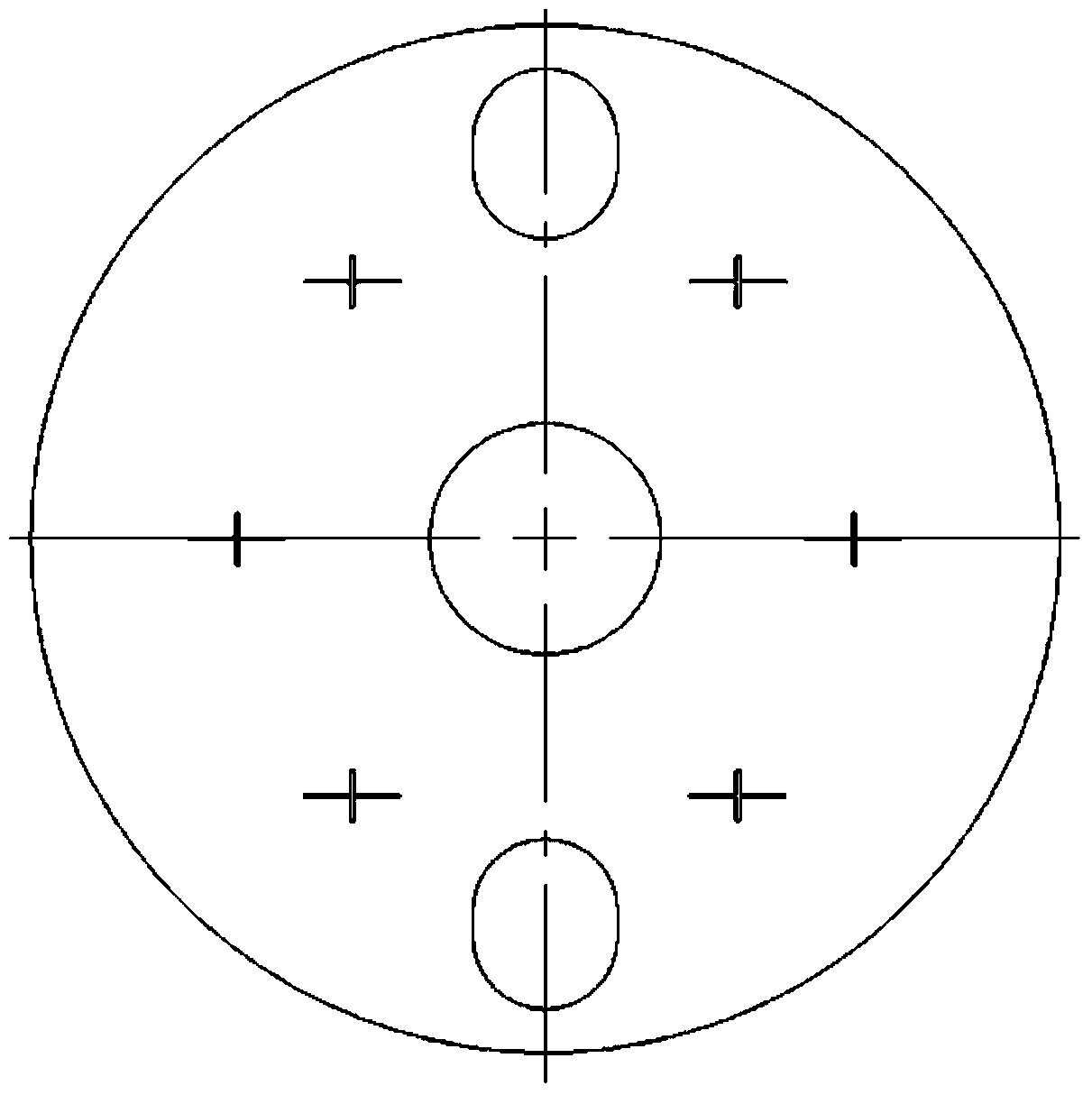

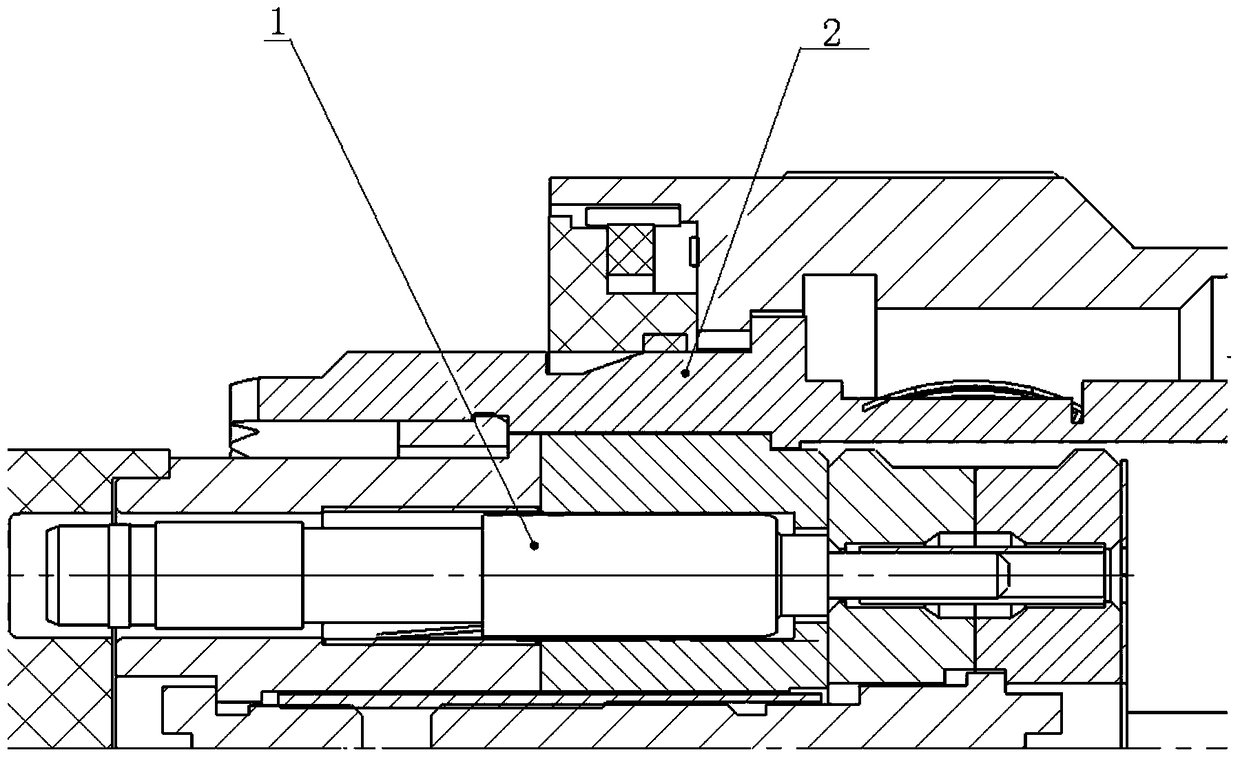

[0015] The self-dustproof structure of the optical fiber connector is composed as follows: an optical fiber ferrule 1, an optical fiber plug 2 and a dustproof non-woven fabric 3; the optical fiber ferrule 1 is installed in the optical fiber plug 2, and the dustproof nonwoven fabric 3 is made of The rubber 4 is bonded to the end of the optical fiber plug 2, and the dust-proof non-woven fabric 3 is provided with a cross hole structure, and the hole position coordinates of the cross hole structure are consistent with the jack hole position coordinates of the optical fiber plug 2. The size of the cross hole structure is the same as the outer diameter of the optical fiber ferrule 1, and the cross hole structure is a closed hole.

[0016] The dust-proof non-woven fabric 3 is provided with a cross hole structure at the same position as the positioning pin, the size of the cross hole structure is the same as the outer diameter of the positioning pin, and the cross hole structure is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com