Device and construction method for controlling verticality and azimuth of rectangular corbel piles

A verticality and corbel technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve waste, prefabricated rectangular corbel pile structure pressing process cannot meet verticality accuracy requirements, drilling grouting obstruction, etc. problem, to achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] refer to Figure 6-8 As shown, the existing prefabricated rectangular corbel piles include a prefabricated rectangular corbel pile main body 11, the top of the prefabricated rectangular corbel pile main body 11 has a pile position control point 14, and the symmetrical two surfaces of the prefabricated rectangular corbel pile main body are respectively installed Ribs 13 are provided, and corbels 12 are respectively installed on the other two symmetrical surfaces.

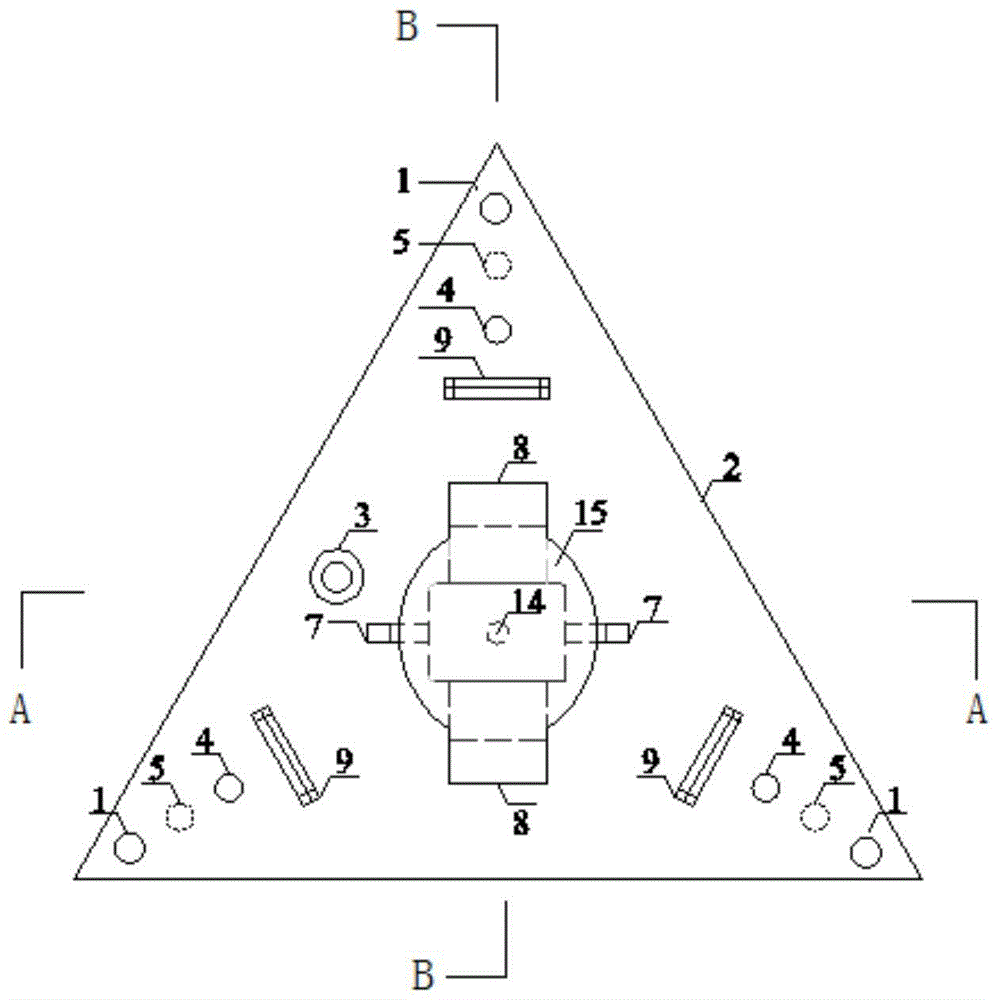

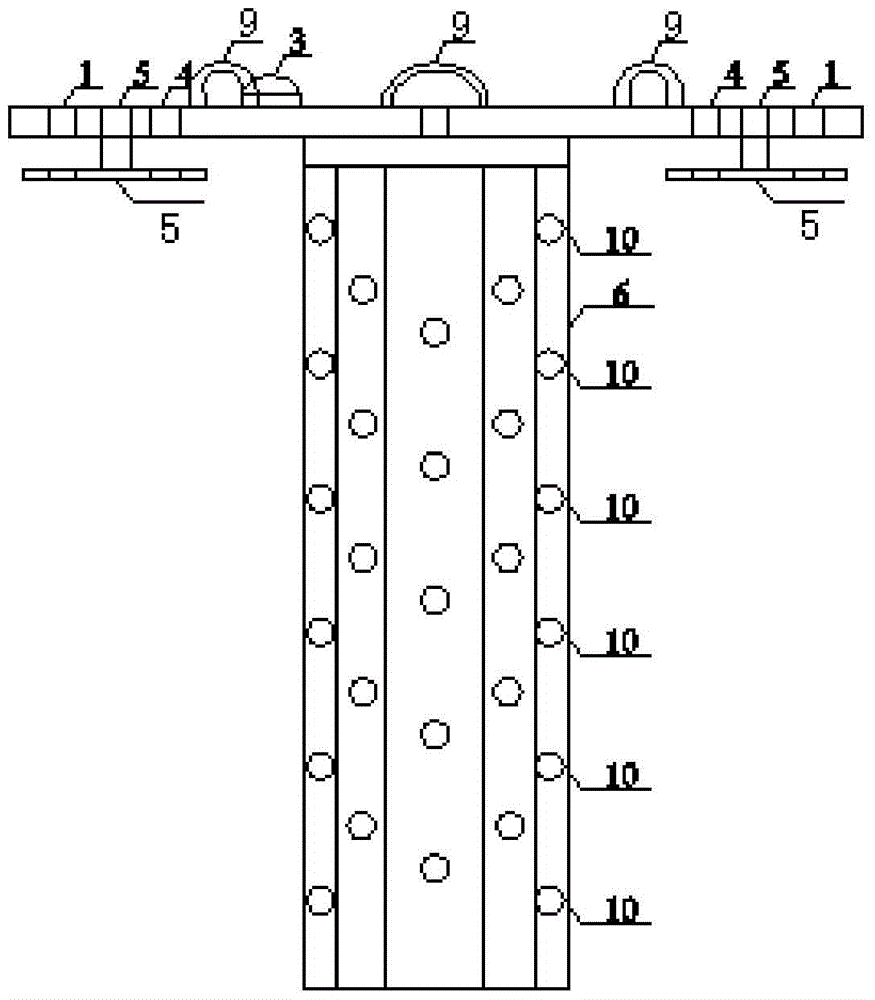

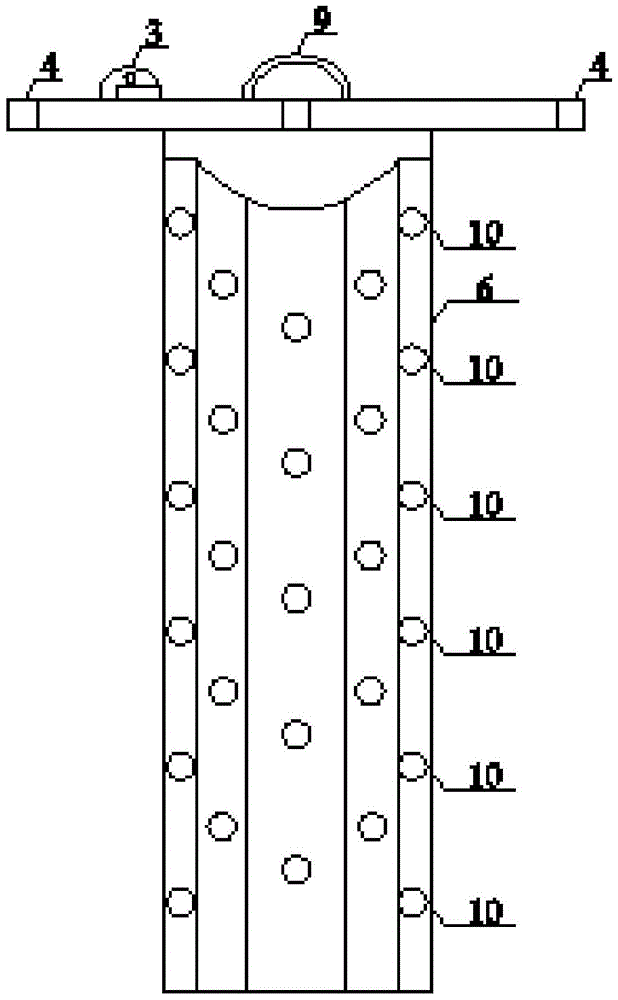

[0049] In order to solve the problems encountered in the construction process of the existing prefabricated rectangular corbel piles, the present invention provides a device for controlling the verticality and azimuth of the rectangular corbel piles. The structure of the device is as follows Figure 1-5 Shown: including the main body support 2, the main body support 2 has a central hole 15, and the lower side of the main body support 2 is fixedly connected with the pile tube 6;

[0050] The other upper side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com