A bridge combined construction method

A construction method and combined technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as high cost, limited construction length, and influence of bridge force, so as to reduce the probability of carbonization and improve construction accuracy , Guarantee the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

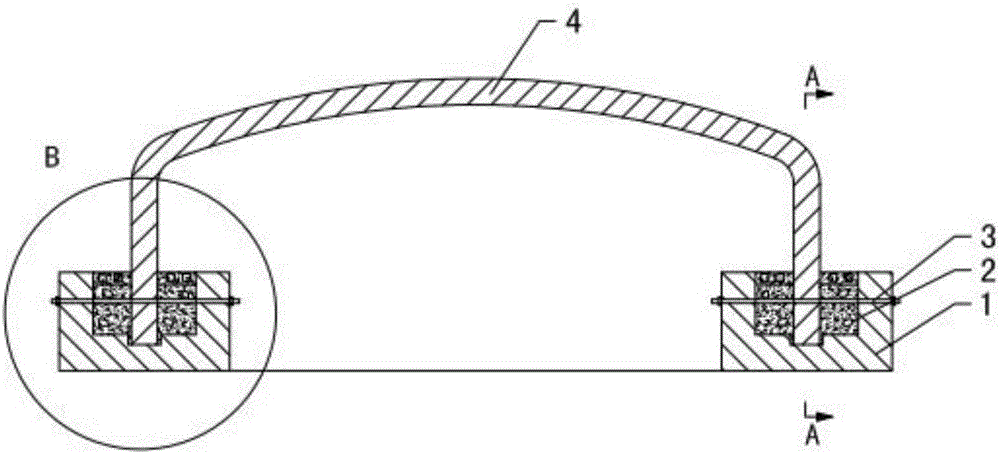

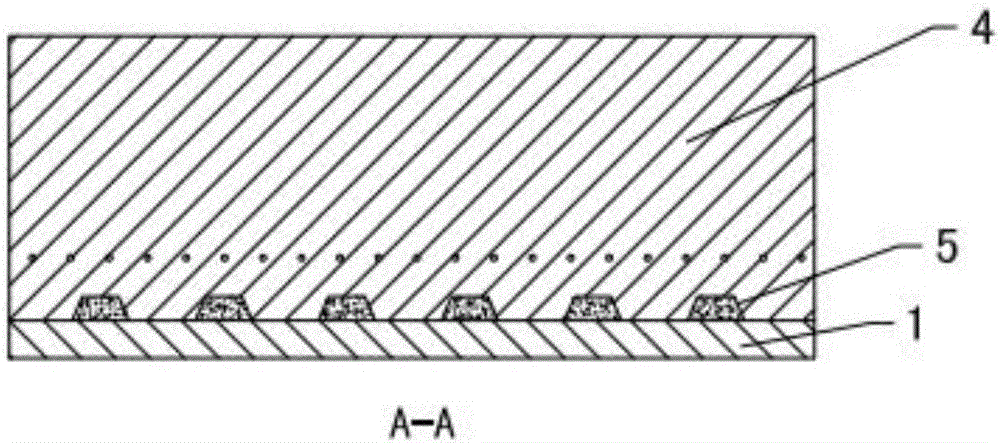

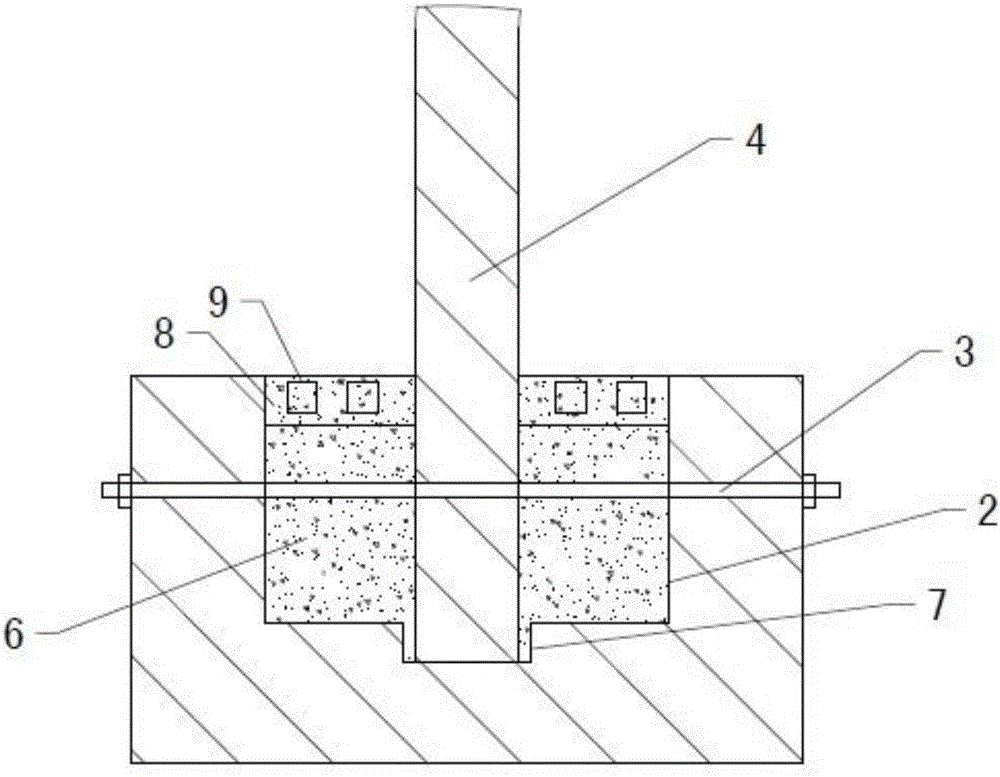

[0030] refer to Figure 1~3 , the combined bridge construction method comprises the following steps:

[0031] S1, making prefabricated parts: making the prefabricated parts of the base 1 and the bridge plate 4, the bridge plate 4 is arched, the upper side of the base 1 is provided with grooves 2 for accommodating the two ends of the bridge plate 4, and the two ends of the bridge plate 4 are provided with transverse The grout hole 5 and the bridge plate fixing hole, the base fixing holes corresponding to the bridge plate fixing holes are provided on the two side walls of the groove 2, and in the process of pouring concrete, the concrete passes through the grout hole 5 from the bridge plate 4 One side flows to the other side, and the concrete on both sides of the bridge plate 4 is connected as a whole through the grout holes 5, so that the bridge plate 4 is fixed more firmly. Furthermore, a positioning groove 7 is provided at the bottom of the groove 2, and the end of the bridg...

Embodiment 2

[0038] refer to Figure 4 , the vibrator used in this embodiment includes a housing 10 and a vibration generating device fixed in the housing 10, the side wall of the housing 10 is provided with a mortar inlet 12, the upper end of the housing 10 is provided with an exhaust port 17, and the lower end is provided with There are mortar outlets 15 . The mortar in the concrete enters the casing 10 through the mortar inlet 12, and the mortar undergoes gas-liquid separation in the casing 10. The mortar is discharged from the mortar outlet 15, and the air contained in the mortar is discharged upward from the exhaust port 17. One is to reduce the air in the mortar. Voids, prevent carbonation, and the second is to improve the strength of concrete.

[0039] Concrete, vibration generator comprises eccentric cylinder 13 and motor 16, and eccentric cylinder 13 is vertically arranged, and the wall thickness of both sides of eccentric cylinder 13 is different, and motor 16 is fixed on the up...

Embodiment 3

[0042] The combined bridge construction method comprises the following steps:

[0043] S1, making prefabricated parts: making the prefabricated parts of the base 1 and the bridge plate 4, the bridge plate 4 is arched, the upper side of the base 1 is provided with grooves 2 for accommodating the two ends of the bridge plate 4, and the two ends of the bridge plate 4 are provided with transverse The slurry passing hole 5 and the fixing hole of the bridge plate, the two side walls of the groove 2 are provided with base fixing holes corresponding to the fixing holes of the bridge plate.

[0044] S2, install the prefabricated parts: fix the base 1 at a predetermined position, hoist the bridge plate 4 to two adjacent bases 1, insert the end of the bridge plate 4 into the groove 2, and pass the fixing part 3 through the fixing hole of the bridge plate and the base fixing hole, and the two ends of the fixing part 3 are fixedly connected with the base 1.

[0045] S3, pouring concrete: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com