Jib-telescopic material lifting device

A hoisting device and boom technology, applied in cranes and other directions, can solve problems such as large rotation space and damage, and achieve the effects of reducing overall length, reducing load-bearing pressure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

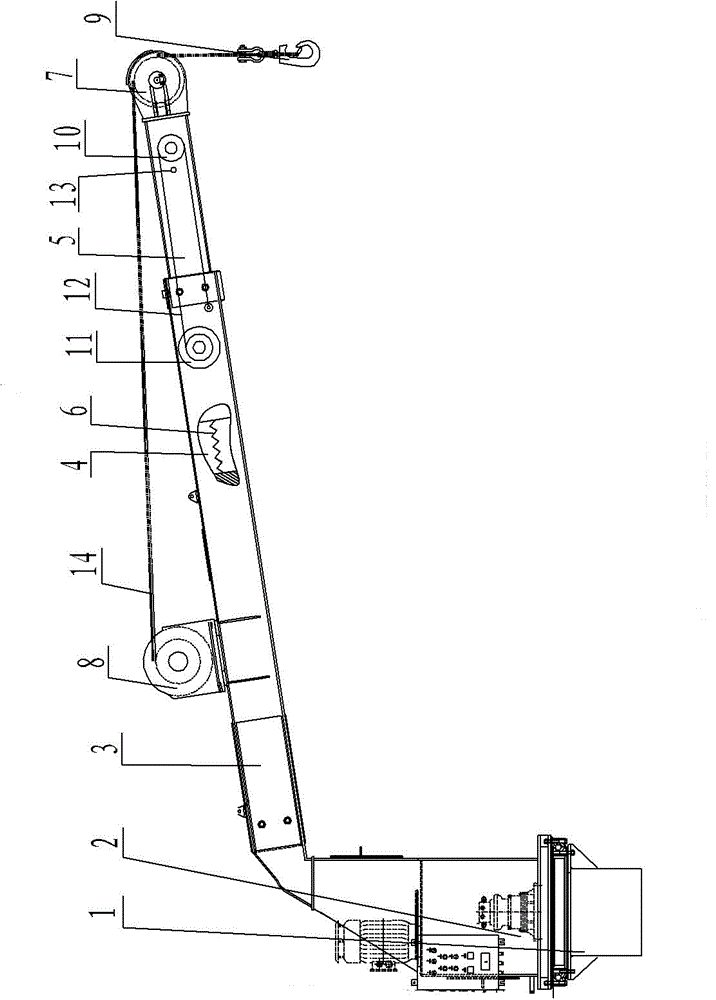

[0009] See figure 1 As shown, a material hoisting device with a telescopic boom includes a base 1, a rotatable turntable 2 is installed on the base 1, a boom 3 is fixedly installed on the turntable 2, and a guide groove 4 is provided on the head of the boom 3. A movable suspender 5 is installed in the guide groove 4, one end of the suspender 5 is connected to the inner wall of the guide groove 4 by a spring 6, the other end is exposed to the guide groove 4 and a guide wheel 7 is installed at the end, the spring 6 is in a compressed state, and the suspension The upper end of the arm 3 is equipped with a hoisting winch 8 that cooperates with the guide wheel 7, one end of the sling 14 is connected to the hoisting winch 8, and the other end passes through the guide wheel 7 to connect to the hook 9, and the side of the boom 5 is equipped with a stretching wheel 10. The stretching winch 11 that cooperates with stretching wheel 10 is installed on the side of arm 3, and one end of str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com