Stage-type driving system for vacuum pipeline train

A technology of vacuum pipes and drive systems, applied in railway car body parts and other directions, can solve the problems of small environmental damage, high maintenance cost, low cost, etc., and achieve the effect of reducing construction cost, reducing mechanical friction resistance, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

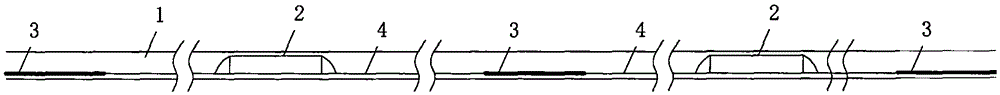

[0012] Embodiments of the present invention are described with reference to the accompanying drawings, below in conjunction with figure 1 The present invention will be specifically described. A staged driving system for a vacuum pipeline train, comprising a vacuum pipeline 1, a high-speed train 2, a driving track 3, and a cruising track 4. The high-speed train 2 runs on the staged track in the vacuum pipeline 1, and the internal arrangement of the vacuum pipeline 1 There is a stage track, and the stage track is composed of a drive track 3 and a cruise track 4. The drive track 3 and the cruise track 4 are alternately arranged in the entire vacuum pipeline 1, and the two starting ends of the stage track are arranged as the drive track 3.

[0013] The driving track 3 does not completely cover the entire vacuum pipeline 1 along the line. The driving track 3 adopts the magnetic levitation linear motor drive technology and the wheel-rail drive technology. The driving track 3 provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com