Nested fireproof thermal-insulation film

A nested, thin-film technology, applied in the field of nested fire-proof and heat-insulating films, can solve the problems of FFC line communication errors, no fire resistance, extrusion flow, etc., to reduce losses, increase flexibility, combine tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be further described below through specific embodiments.

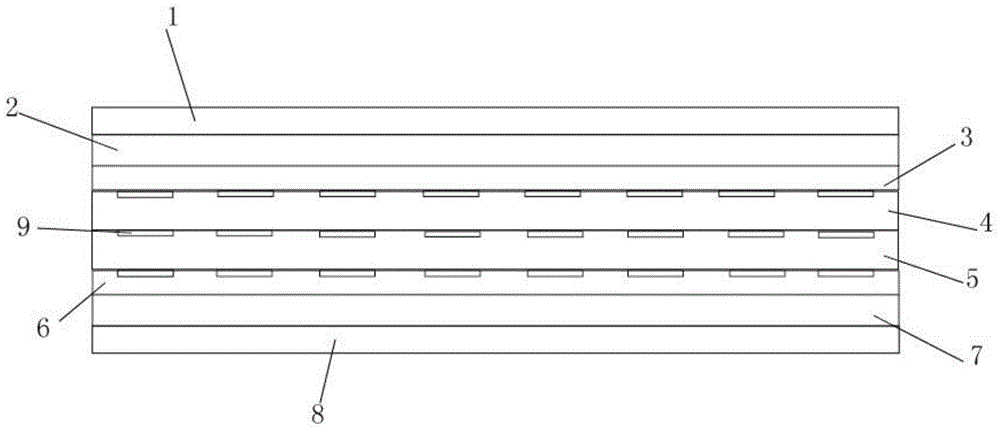

[0013] like figure 1 As shown in the figure: 1 is the first waterproof layer, 2 is the first PET layer, 3 is the first buffer layer, 4 is the fireproof hot melt adhesive layer, 5 is the flame retardant layer, 6 is the second buffer layer, 7 is the The second PET layer, 8 is the second waterproof layer, and 9 is the reinforcement groove.

[0014] The nested fireproof and heat-insulating film is composed of a first waterproof layer, a first PET layer, a first buffer layer, a fireproof hot melt adhesive layer, a flame retardant layer, a second buffer layer, a second PET layer and a second waterproof layer, The second waterproof layer is coated with a second PET layer, the second PET layer is coated with the second buffer layer, the second buffer layer is evenly provided with reinforcement grooves, and the reinforcement grooves are arranged at equal distances in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com