Tread comprising a directional tread pattern

A tread and pattern block technology, which is applied in the direction of tire tread/tread pattern, transportation and packaging, tire parts, etc., can solve problems such as hindering water flow, and achieve the effect of improving lateral grip and increasing slenderness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

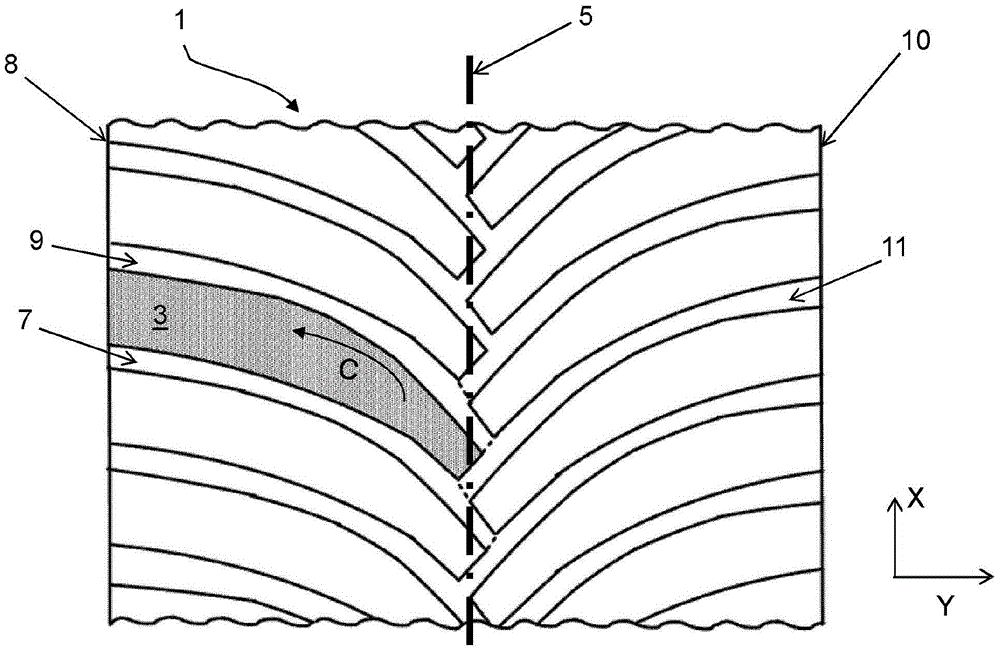

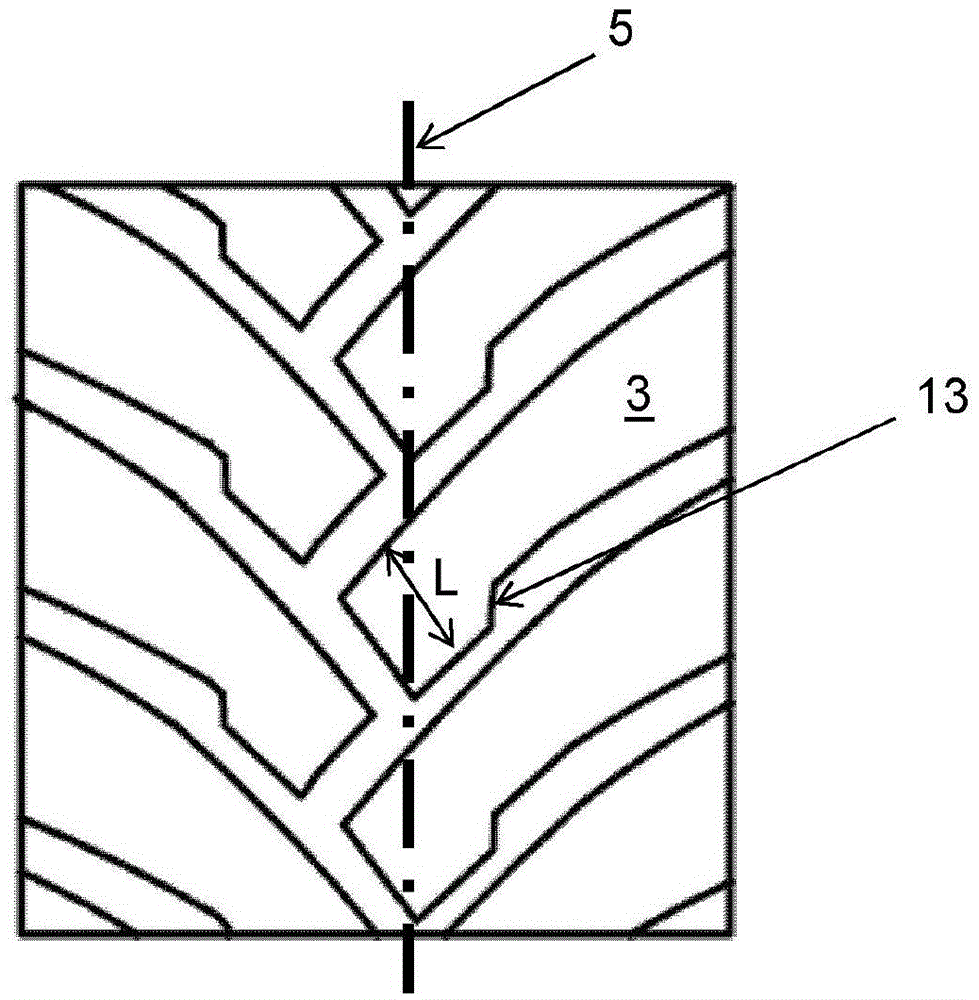

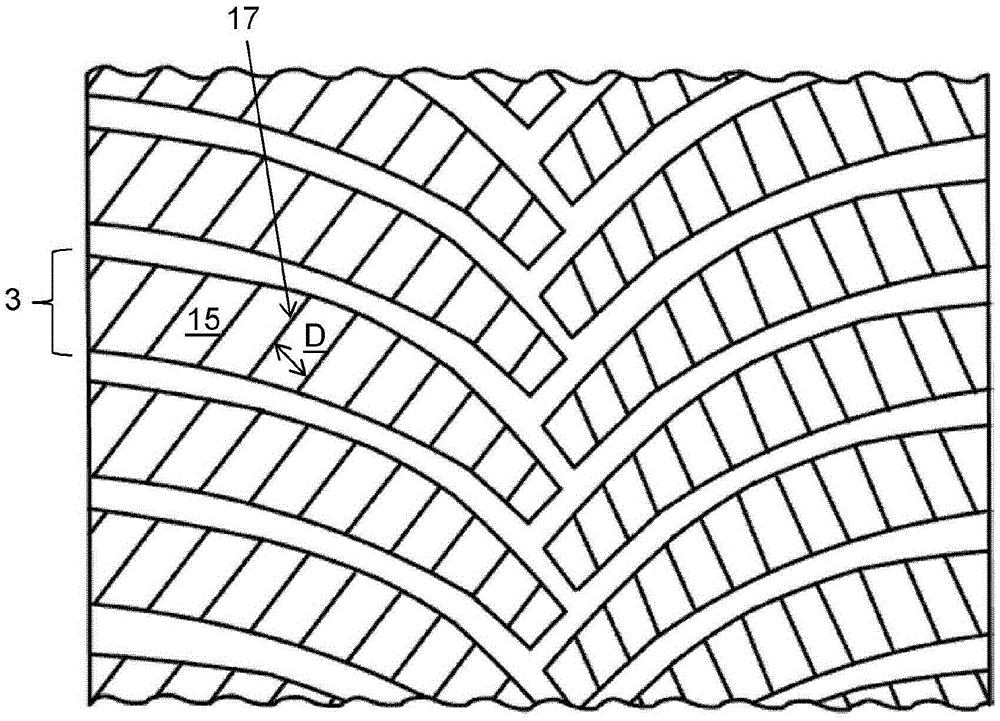

[0036] figure 1 A partial view of a tread 1 according to a first embodiment of the invention is schematically depicted.

[0037] The tread 1 comprises a plurality of rubber blocks 3, one of which has here been painted gray to make the invention easier to understand. Said blocks are formed on each side of a median plane 5 which divides the tread 1 into two parts. Here, each block 3 extends continuously towards the outside of the tread at the median plane 5 , ie said block is not divided in the direction of the outside of the tread by circumferential grooves and / or offset grooves. More particularly, each block is delimited by a first groove 7 , a second groove 9 and a third groove 11 . A first groove 7 extends at the median plane 5 towards the first edge 8 of the tread and a second groove 9 also extends at the median plane 5 towards this same first edge 8 but with an offset in the circumferential direction . The first groove 7 and the second groove 9 have the same curvature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com