Method for preparing alloy pre-stretched plates

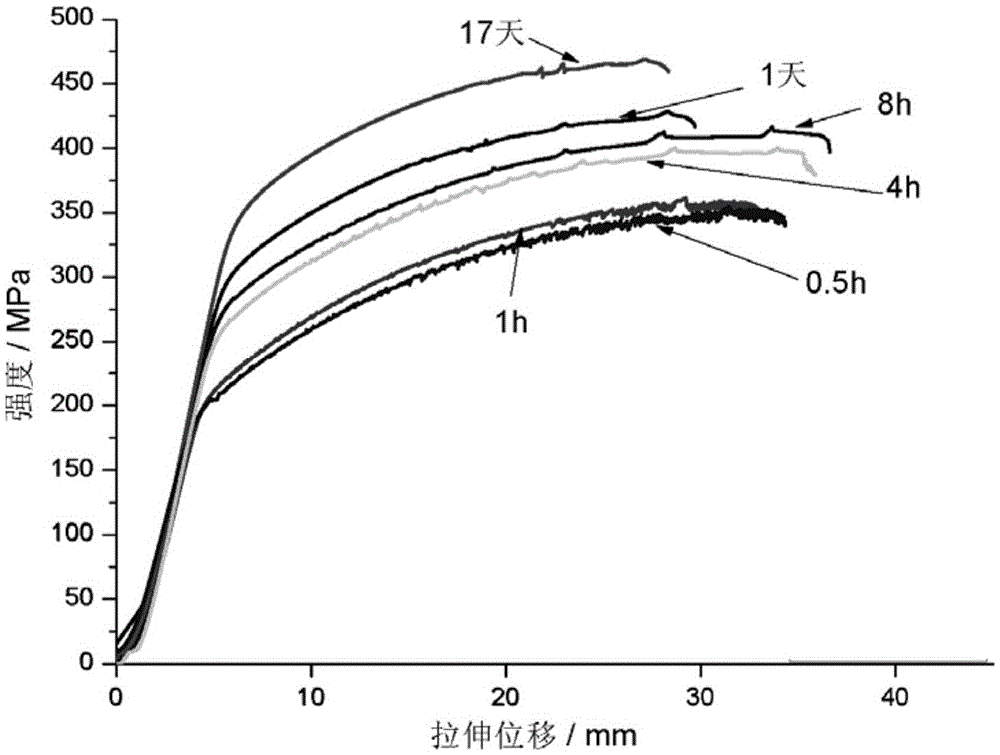

A technology for alloy sheets and aluminum alloy sheets, applied in the field of alloys, can solve the problems of difficulty in maintaining stable strength, and achieve the effects of alleviating the effect of strain aging and eliminating slip lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing an alloy pre-stretched sheet, comprising the following steps:

[0023] a) The raw material of the alloy plate is subjected to quenching treatment and natural aging treatment for more than 8 hours in sequence, and then pre-stretched to obtain the alloy pre-stretched plate.

[0024] In the method provided by the present invention, firstly, quenching treatment is carried out on the raw material of the alloy plate. Wherein, the alloy sheet material is preferably an aluminum alloy sheet material. In an embodiment provided by the present invention, the content of Si in the aluminum alloy plate is 0.1-0.2 wt%. In an embodiment provided by the present invention, the content of Fe in the aluminum alloy plate is 0.15-0.2 wt%. In an embodiment provided by the present invention, the content of Cu in the aluminum alloy plate is 3.6-4.0 wt%. In an embodiment provided by the present invention, the content of Mn in the aluminum alloy pla...

Embodiment 1

[0030] The 2A96 aluminum-lithium alloy plate (size: 10×1200×7200mm) is first quenched, wherein the heating temperature is 520°C, the holding time is 60 minutes, and the cooling medium is water at room temperature; then the quenched aluminum alloy plate is subjected to 8h Natural aging treatment; finally pre-stretching the aluminum alloy plate, wherein the stretching rate is 102 mm / min, the pre-stretching rate is 2.8%, after the pre-stretching is completed, the pre-stretched aluminum alloy plate is obtained.

Embodiment 2

[0032] The 2A96 aluminum-lithium alloy plate (size: 10×1200×7200mm) is first quenched, wherein the heating temperature is 520°C, the holding time is 60 minutes, and the cooling medium is water at room temperature; after that, the quenched aluminum alloy plate is treated for 24 hours Natural aging treatment; finally pre-stretching the aluminum alloy plate, wherein the stretching rate is 120mm / min, the pre-stretching rate is 3.1%, after the pre-stretching is completed, the pre-stretched aluminum alloy plate is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com