Specific track rotating arm type hydraulic tensioning device for vehicle body assembly

A tensioning device and a swivel-arm type technology, applied in vehicle parts, transportation and packaging, metal processing, etc., can solve the problems of unstable tensioning force, low work efficiency, and the deflection of the vehicle body cannot meet the requirements, and achieve improved performance. Assembly efficiency and accurate body deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

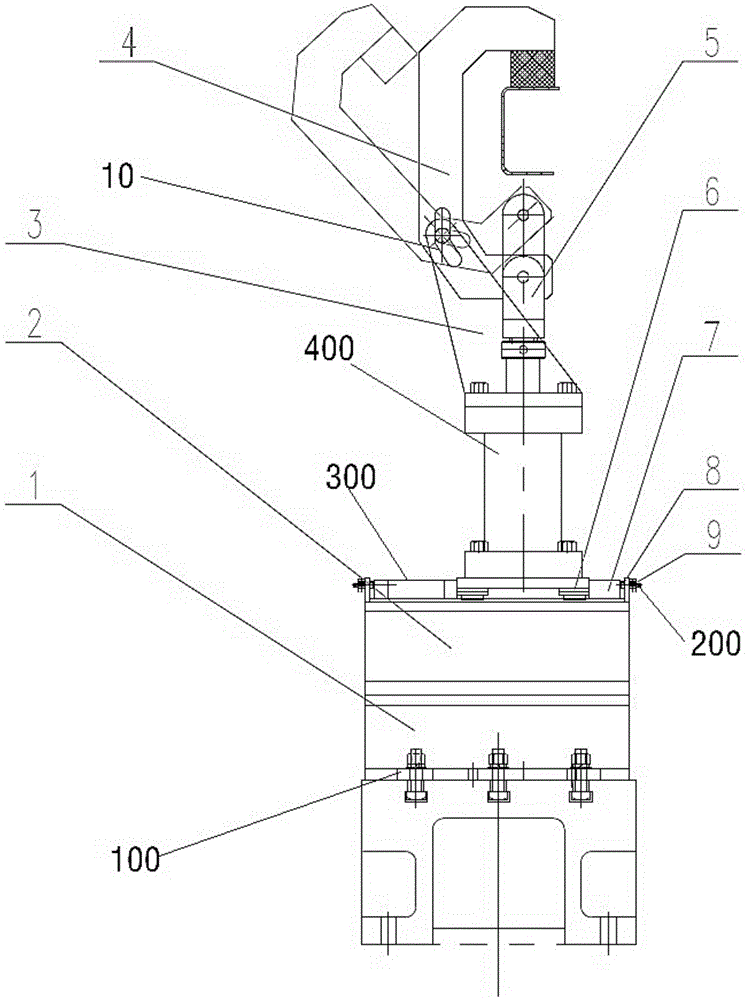

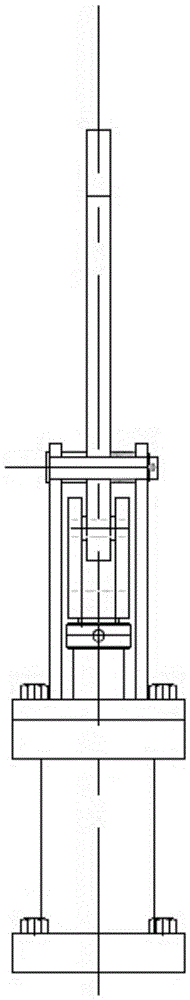

[0020] As shown in the figure: 1—longitudinal base; 2—horizontal base; 3—support plate; 4—press arm; 5—connecting block; 6—linear guide pair; 7—adjusting pad; 8 ——adjusting screw; 9—nut; 10—chute; 100—longitudinal adjustment mechanism; 200—locking mechanism; 300—width adjustment mechanism; 400—hydraulic drive mechanism.

[0021] A specific track rotary arm type hydraulic tensioning device for vehicle body assembly includes a hydraulic drive mechanism and a pressing mechanism;

[0022] The pressing mechanism includes a pressing arm. The pressing arm is a C-shaped structure. One point of the C-shaped pressing arm is rotatably connected with the connecting block, and the other end is an open end and uses the inner side to press the assembled vehicle body. The chute, the axis of the chute is parallel to the vertical side of the C-type, the pin body passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com