Control method for equipment for automatically binding wire harness by using plastic binding tape

A technology of plastic cable ties and control methods, which is applied to automatic control of packaging, binding materials, paper/cardboard containers, etc., can solve the problems of poor production quality, bulky, low production efficiency, etc. Simple control steps and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

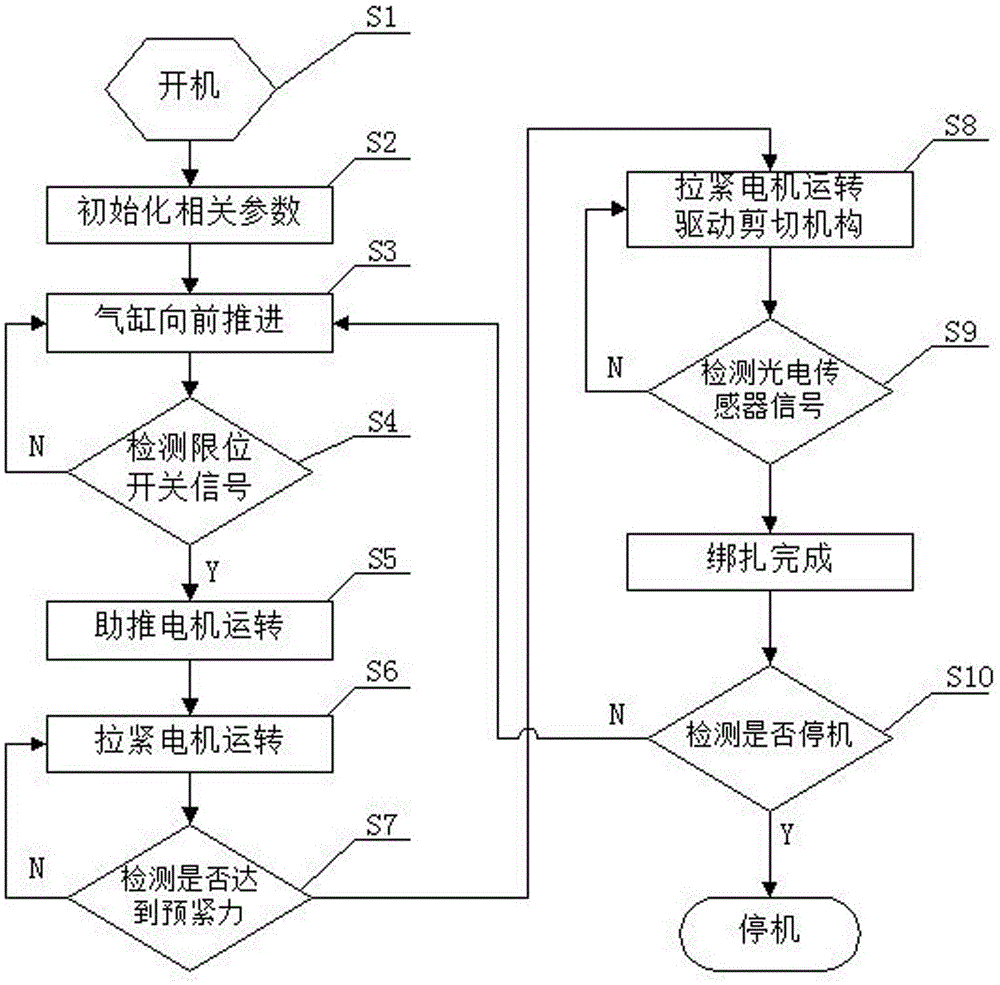

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

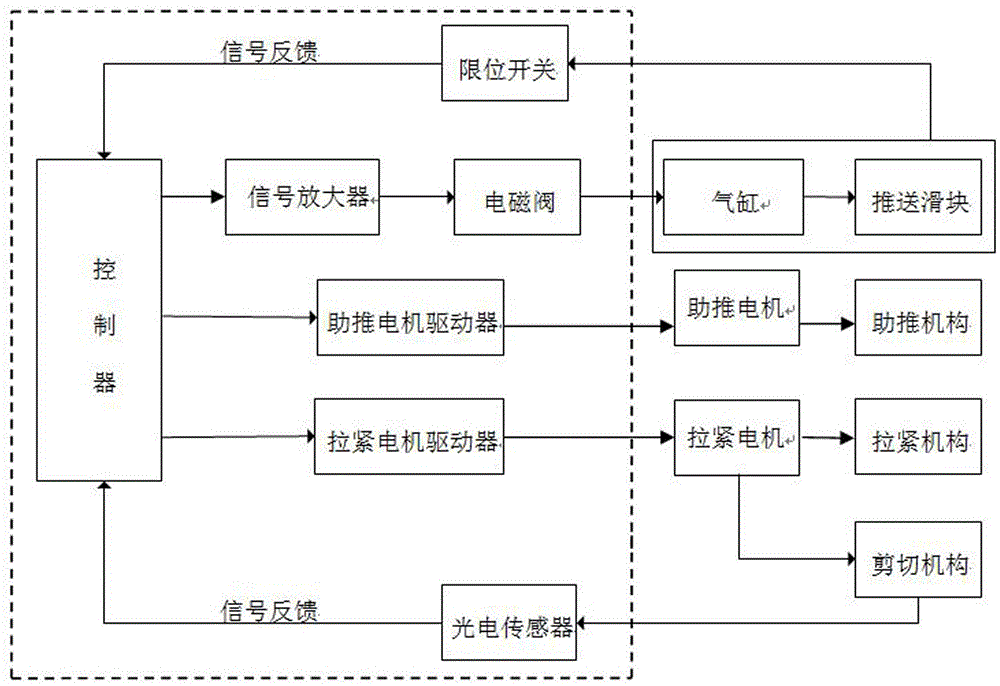

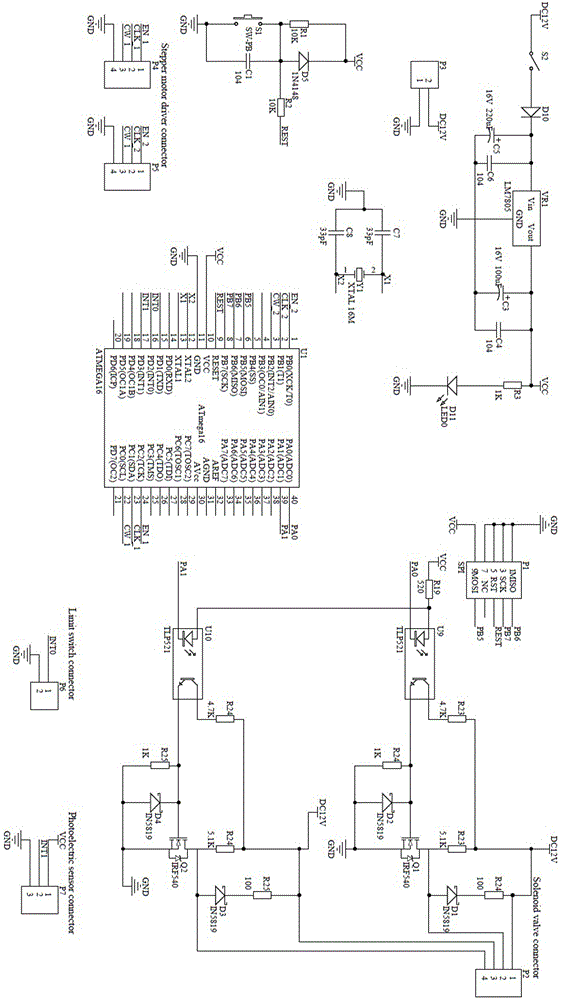

[0033] like figure 1 As shown, the control system includes: a controller, a feeding control unit, a binding control unit, and a cutting control unit.

[0034] The controller is an 8-bit AVR single-chip microcomputer with high performance and low power consumption, and the specific model is an ATmega16 single-chip microcomputer, which is connected to the feeding control unit, the binding control unit, and the cutting control unit respectively through an interface circuit. Specifically which parts are connected are as follows.

[0035] The feeding control unit includes: a signal amplifier, a solenoid valve and a limit switch. The signal amplifier is connected to the controller. The solenoid valve is driven by the signal to control the movement of the cylinder in the push mechanism, and then drives the push slider; the limit switch is installed on the push On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com