A new type of railway wagon for piggyback transportation

A railway freight car and piggyback technology, which is applied in the direction of transporting passenger cars, railway car body parts, freight cars, etc., can solve the problems of complex structure, heavy weight, etc., and achieve the effect of reducing manufacturing costs and reducing power performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

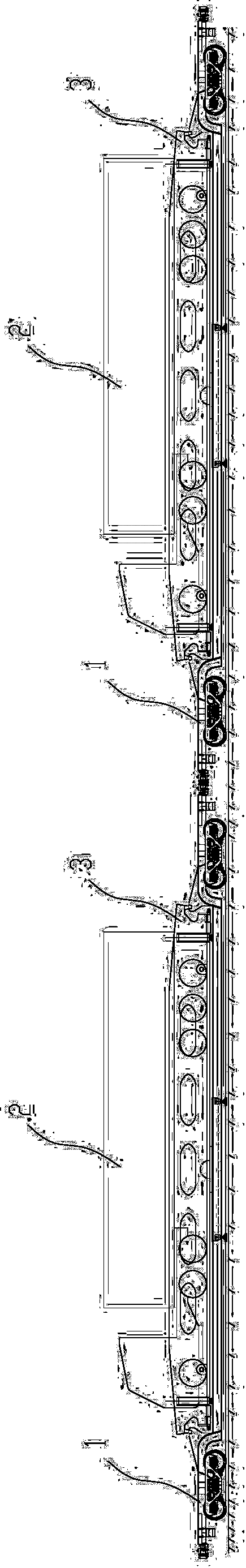

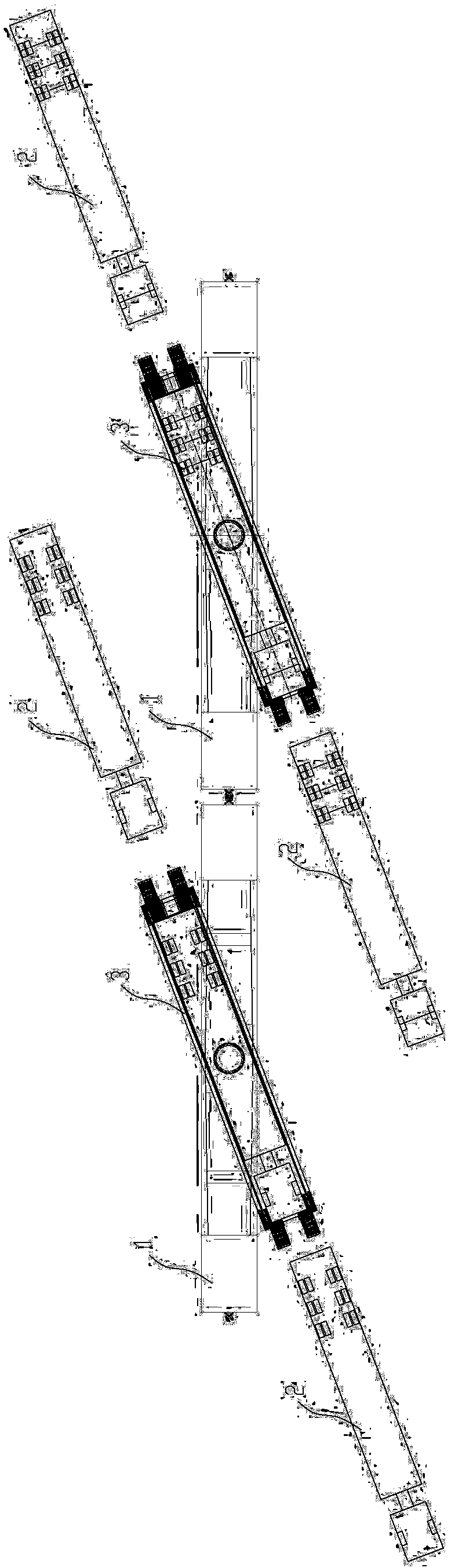

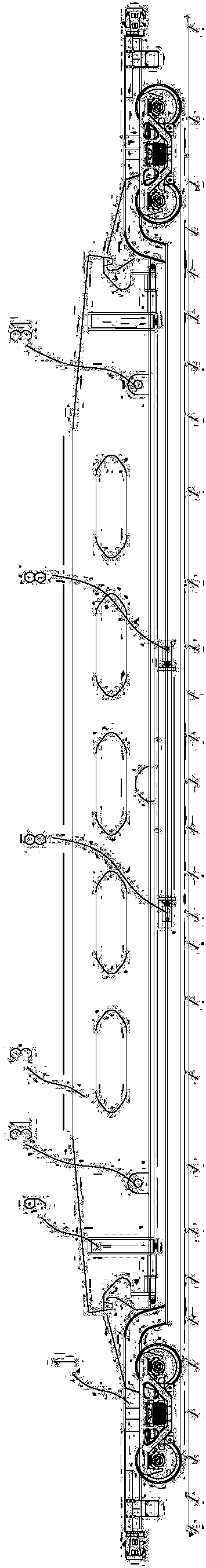

[0046] The core of the present invention is to provide a novel railway wagon for piggyback transportation with simple structure.

[0047] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] It should be noted that the front and rear, up and down, left and right directions mentioned in this article are all referenced to the railway freight car, and the direction parallel to the traveling direction of the railway freight car is the longitudinal direction. In the longitudinal direction, the direction pointed by the traveling direction is the front, and The direction opposite to the direction is the rear; in the plane parallel to the running track surface of the railway freight car, the direction perpendicular to the longitudinal direction is the transverse direction, and in the transvers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com