Electric vehicle battery charger comprising a pfc circuit

一种功率因数校正、电池充电器的技术,应用在电动汽车充电技术、电动汽车、输出功率的转换装置等方向,能够解决没有解决方案等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

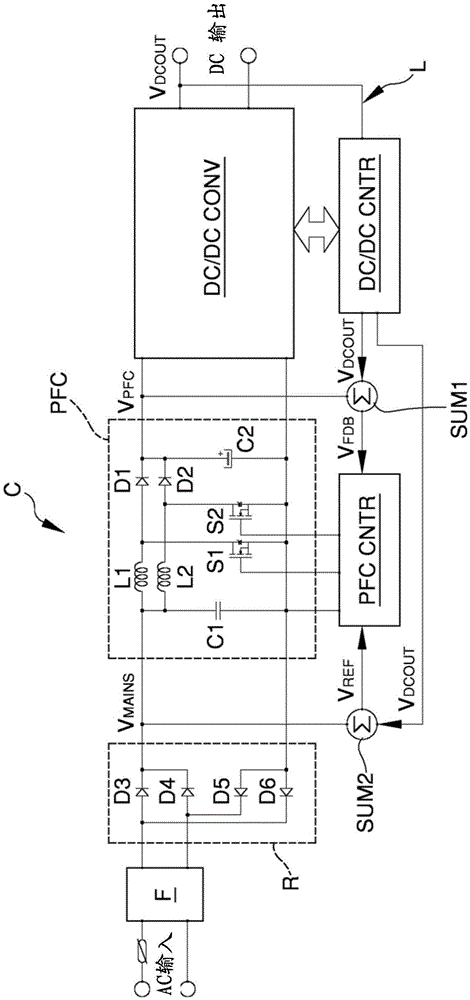

[0019] With particular reference to the drawings, a battery charger can be indicated generally by reference C, which can be used to charge the battery of an electric vehicle.

[0020] Specifically, the electric vehicle battery charger C includes:

[0021] - Resonant DC / DCCONV voltage converter;

[0022] - PFC power factor correction circuit connected upstream of the DC / DCCONV voltage converter;

[0023] - a PFCCNTR controller circuit connected to the PFC correction circuit for directing the correction circuit to correct the power factor and supplying a stable output DC voltage V PFC .

[0024] Specifically, the DC / DCCONV voltage converter includes a DC / DC converter using resonant LLC technology.

[0025] Advantageously, the battery charger C further includes a feedback line L, which is respectively connected to the output terminal of the DC / DCCONV voltage converter and an input terminal of the PFCCNTR controller circuit.

[0026] In particular, the PFCCNTR controller circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com