Shore durometer for detecting plastic hardness

A Shore hardness tester and hardness technology, which is applied in the field of auxiliary equipment for the production of plastic granules, can solve the problems of Shore hardness tester use and promotion restrictions, indenter easily subject to wear, single function, etc., to achieve practicality and functional perfection, Promote the use and promotion, reduce the effect of bumps and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

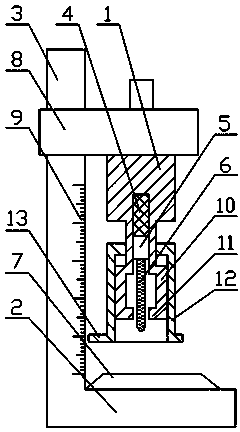

[0012] The invention includes a detection body 1, a base 2, a side arm 3, a pressure needle installation block 4, a sensor 5, a pressure needle 6, a measuring platform 7, a lifting slider 8, a scale 9, an inner cylinder 10, a pressure foot 11, a protection When installing the outer cylinder 12 and the indicator strip 13, the scale 9 is first installed on the side arm 3, the side arm 3 is installed on the upper end of the base 2, the measuring platform 7 is installed on the upper end of the base 2, and then the detection body 1 Install the inner cylinder 10 inside, set the presser foot 11 at the lower end of the installation inner cylinder 10, then install the pressure needle 6 on the lower end of the pressure needle installation block 4 through the sensor 5, and install the pressure needle installation block 4 on the installation inner cylinder 10 Then install the indicator strip 13 on the lower end of the protection outer cylinder 12, install the protection outer cylinder 12 o...

Embodiment 2

[0014] When in use, first put the test sample on the measuring table 7, adjust the lifting slider 8 downwards, so that the lower end of the protection outer cylinder 12 contacts the test sample, at this time the indicator strip 13 and the scale 9 represent the test sample Continue to adjust the lifting slider 8 downwards, so that the protection outer cylinder 12 moves upward relative to the installation inner cylinder 10. At this time, the pressure needle 6 presses into the test sample, and when the press foot 11 is in full contact with the test sample, it passes through the sensor. 5 Detect the Shore hardness of the test sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com