Method for rapidly detecting and evaluating compaction quality of road inorganic stabilized grain base

A technology of inorganic stability and compaction quality, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of many human influence factors, inability to reflect mechanical properties, and small evaluation range, so as to save single-point detection costs and avoid artificial The effect of interfering with data and requiring fewer personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

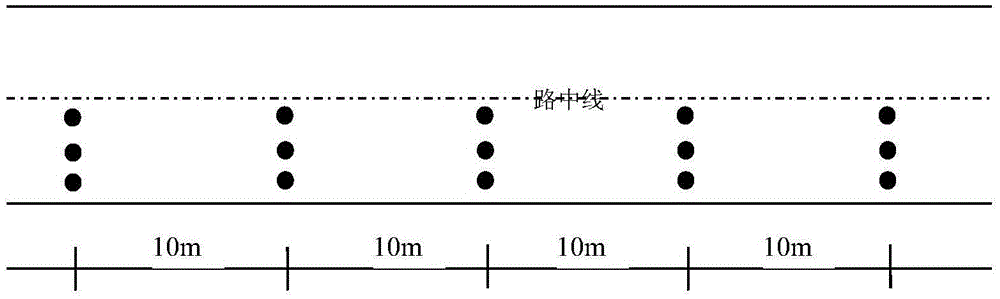

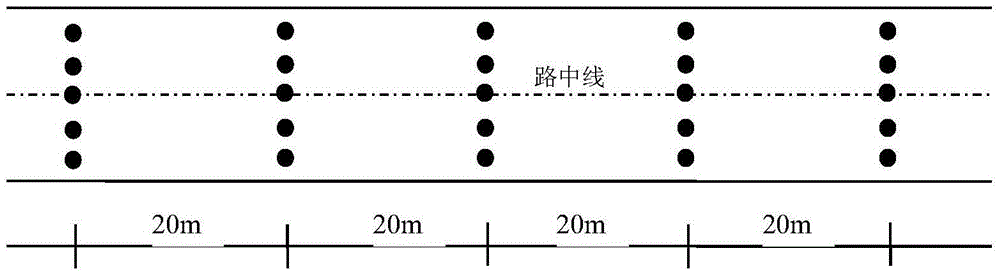

[0031] The invention provides a method for fast and non-destructive detection and evaluation of the compaction quality of road inorganic stable granular materials, by using a portable falling weight deflection instrument (PFWD) to detect the deformation modulus value Evd of the base material under different compaction degrees , to establish the relationship between the degree of compaction and Evd, according to the standard of degree of compaction, put forward the detection standard Evd under different degrees of compaction 0 ; Evd obtained from the det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com