Sealing tightness testing device for high-performance battery

A sealing detection and detection device technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the rate of increase and deceleration of the fluid, can solve problems such as high price, decreased battery charge performance, and fire, and achieve High degree of automation, stable work and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

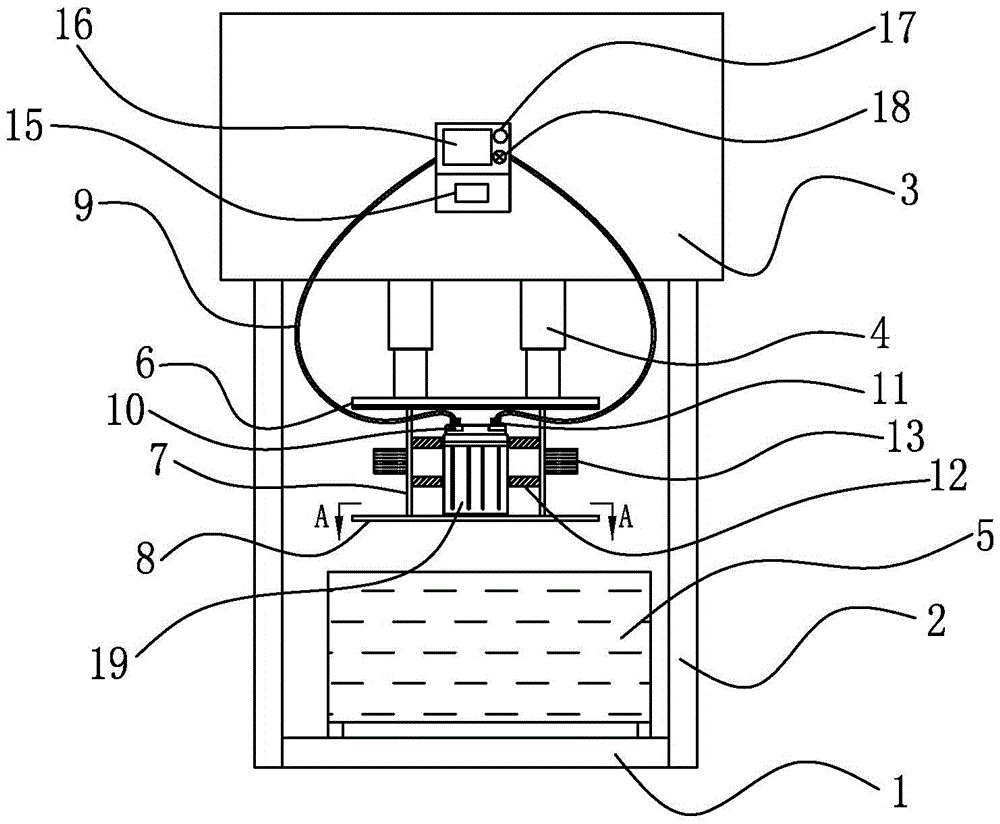

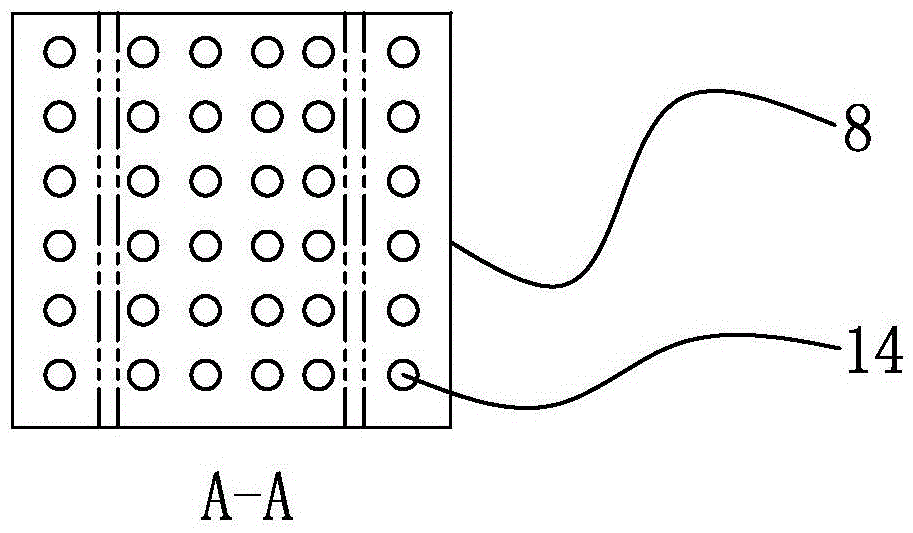

[0019] Example: such as Figure 1-2 As shown, the sealing detection device of the high-performance storage battery includes a support frame device, a support cabinet 3 corresponding to the support frame device, and a detection device; the detection device is located at the lower part of the support cabinet 3; the support cabinet 3 is provided with a test device, This inspection device is connected with the injection port 10 of storage battery 19 by test tube 9, and the end of injection port 10 and test tube 9 is connected with sealing ring 11; Test tube 9 is a retractable sealing tube; like this, in the test process, we It can move up and down through the lifting device 4 without affecting the accuracy of the test.

[0020] The support frame device includes a placement board 1 and support columns 2 located on both sides of the placement board 1, and the detection device includes a test slot 5, a lifting device 4, a placement rack device fixedly connected with the lifting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com