A magnetorheological fluid damping platform with quasi-zero stiffness

A magnetorheological fluid, quasi-zero stiffness technology, used in shock absorbers, shock absorbers, machines/supports, etc. problem, to achieve the effect of reducing dynamic stiffness, large vibration isolation frequency range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

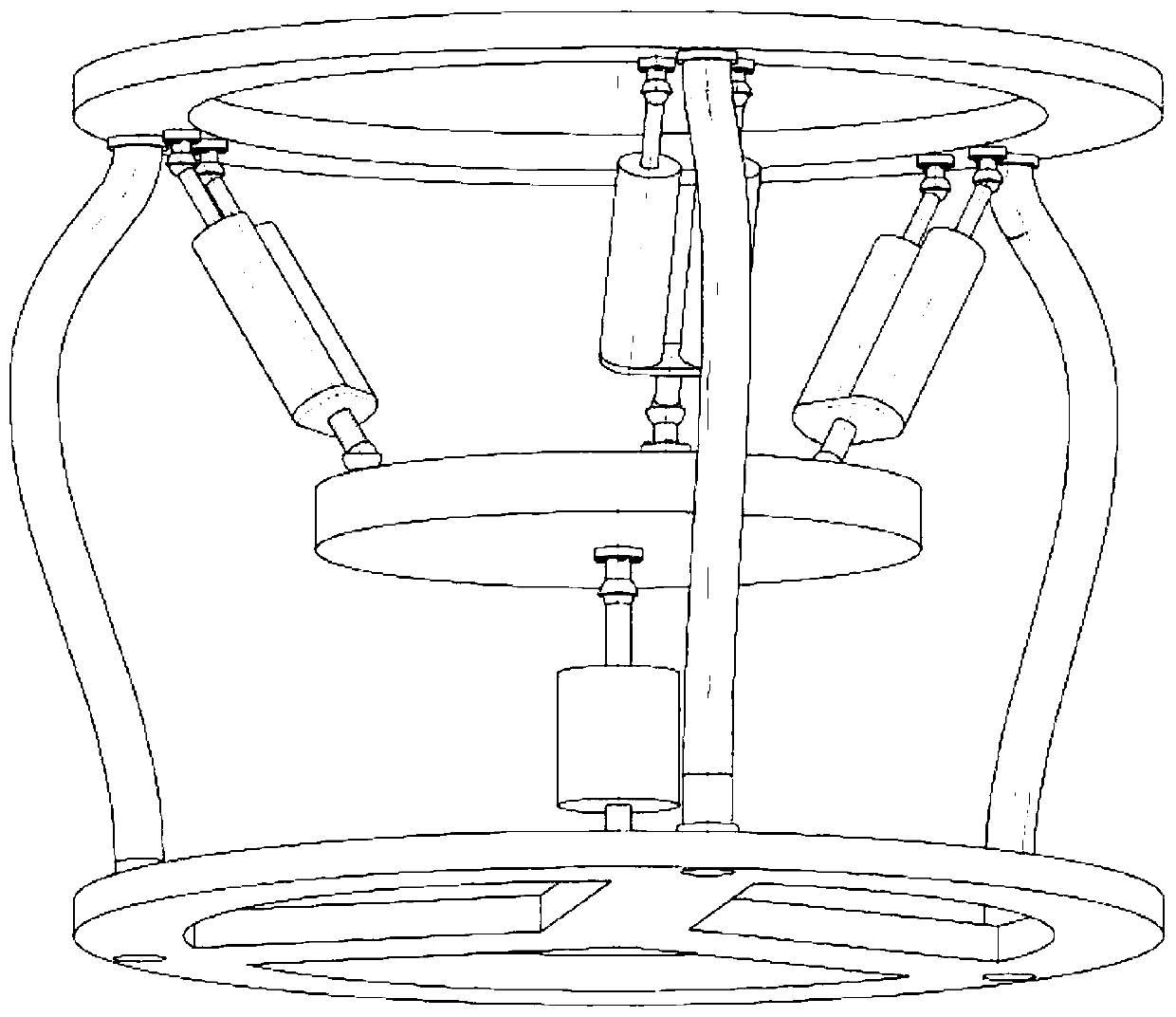

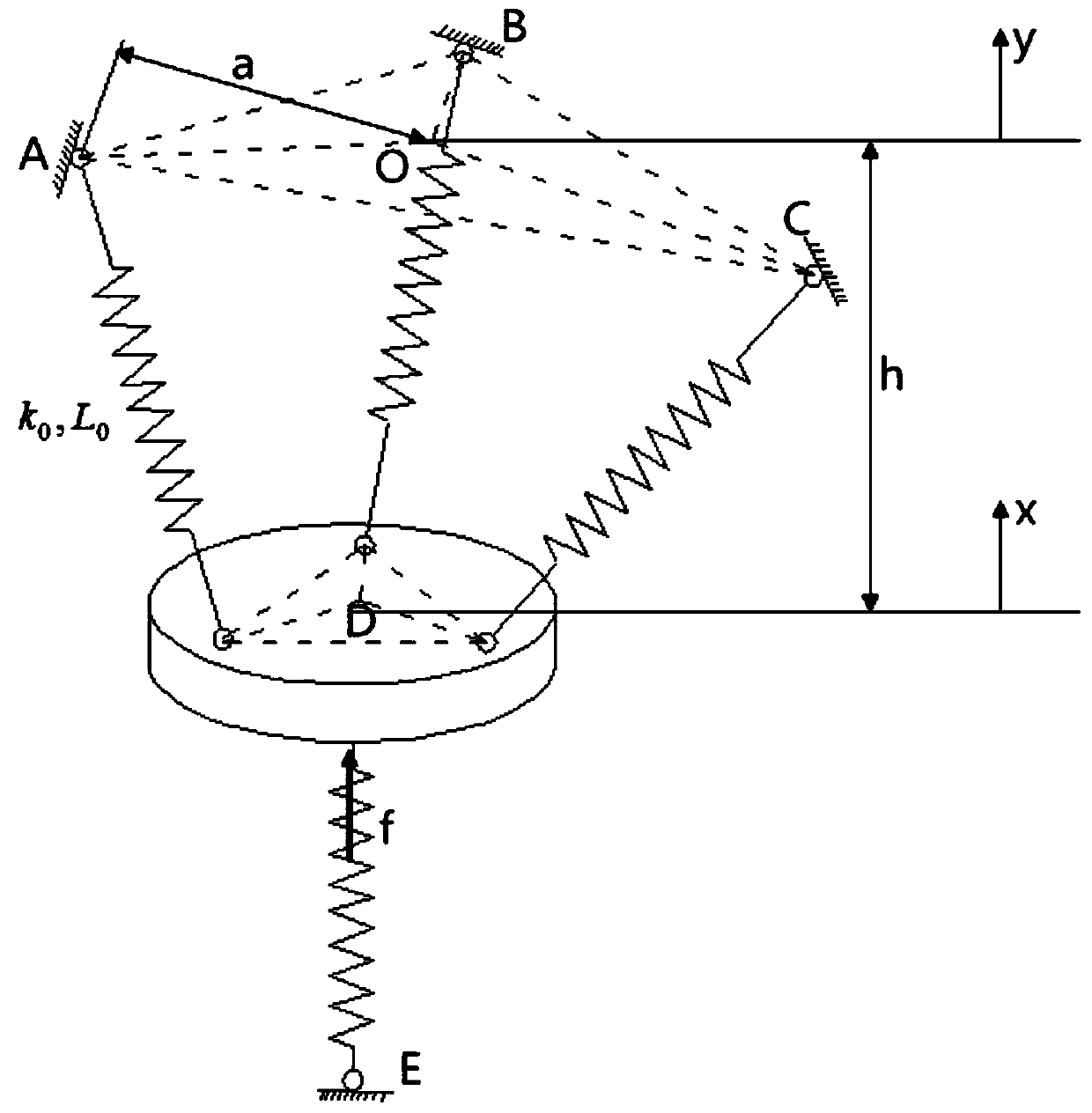

[0063] Such as figure 1 , 2 As shown, this example provides a magneto-rheological fluid damping platform with quasi-zero stiffness, including the upper spherical joint seat 1 of the double-tube shock absorber, the bolts and nuts of the upper fixing platform 2, and the double-tube magnetorheological fluid shock absorber 3 , moving platform 4, bracket 5, single-tube magnetorheological fluid shock absorber lower ball hinge seat 6, lower solid platform 7, single-tube magnetorheological fluid shock absorber 8, double-tube magnetorheological fluid shock absorber lower ball Hinge seat 9, cargo placement place 10, upper solid platform 11, upper spherical hinge seat 12 of single-tube magnetorheological fluid shock absorber, bolt 13 of upper ball hinge seat of single-tube magnetorheological fluid shock absorber. The peripheral fixed platform mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com