Single-stage centrifugal pump capable of achieving self balance of axial force

A self-balancing, axial force technology, applied to the components, pumps, pump components, etc. of the pumping device for elastic fluid, can solve the problem of large axial force, achieve smooth flow, reduce vibration, and restrain steam. Erosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

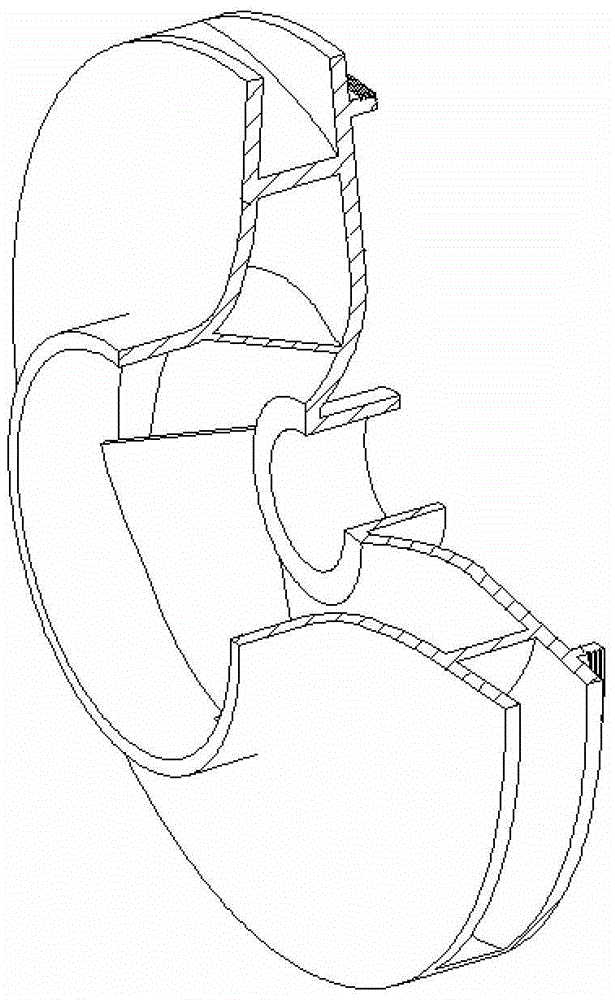

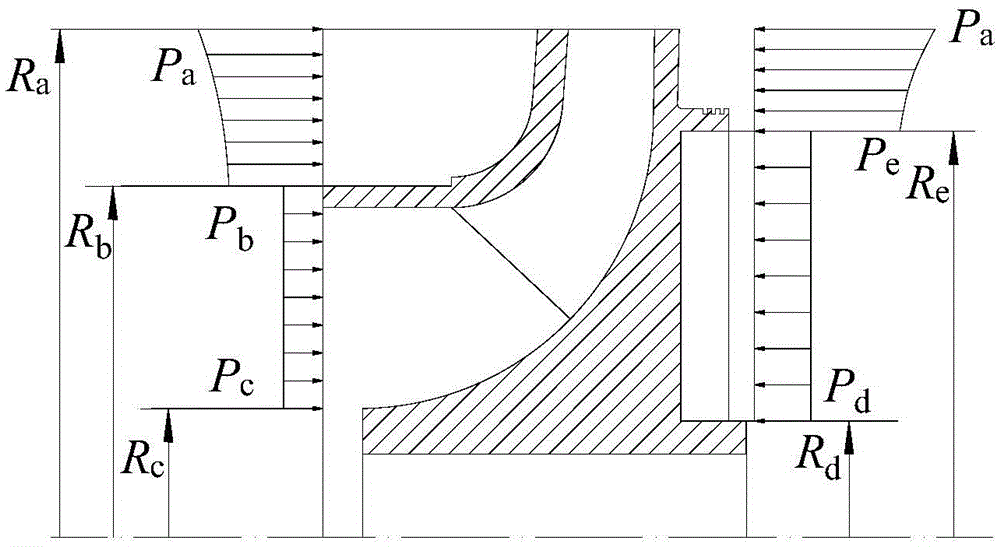

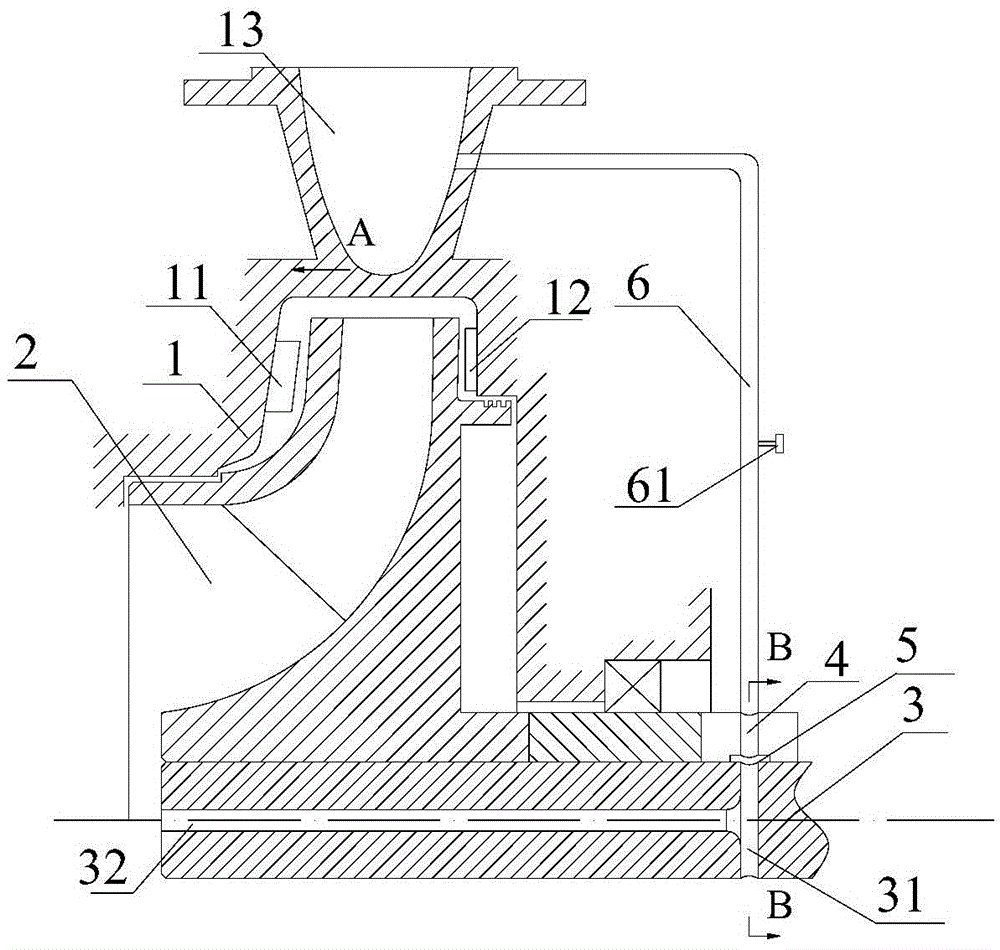

[0041]Embodiment 1 A single-stage centrifugal pump capable of self-balancing axial force described in the present invention includes a pump body 1, an impeller assembly 2, a pump shaft 3 and a shaft sleeve 4, and one end of the pump shaft 3 extends into Inside the pump body 1, the pump shaft 3 is sealingly connected with the pump body 1 through the shaft sleeve 4, and the pump shaft 3 is in clearance fit with the shaft sleeve 4; the impeller assembly 2 Installed on the end of the pump shaft 3 protruding into the pump body 1, the impeller assembly 2 is in clearance fit with the impeller installation cavity inside the pump body 1; the impeller assembly 2 includes an impeller 21, an impeller The front cover 22 and the impeller rear cover 23, the impeller 21 is installed in the cavity surrounded by the impeller front cover 22 and the impeller rear cover 23, and the impeller rear cover 23 The rear part of the impeller constitutes a balance chamber, and the balance chamber of the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com