High-speed electromagnetic valve drive method with boosting and fault diagnosing functions and circuit

A high-speed solenoid valve, drive circuit technology, applied in electrical control, engine control, machine/engine, etc., can solve the problem of inability to realize solenoid valve circuit breaker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0049] The present invention will be described in detail below with reference to the accompanying drawings and examples.

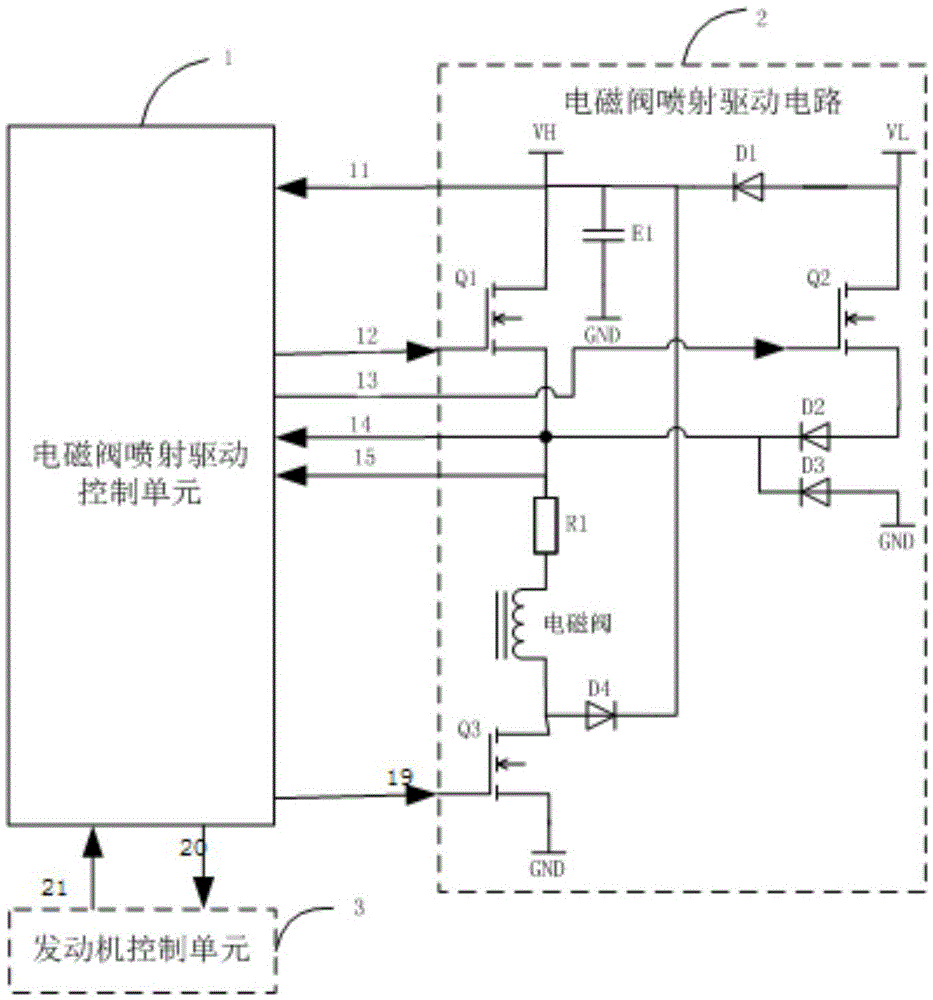

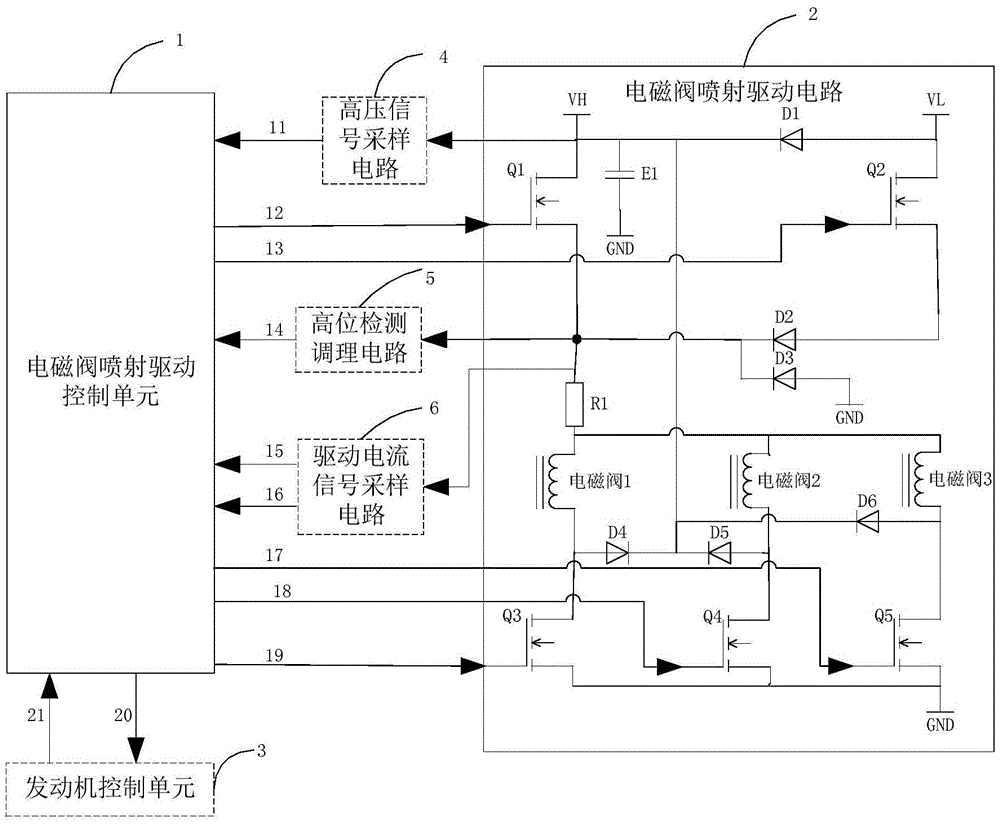

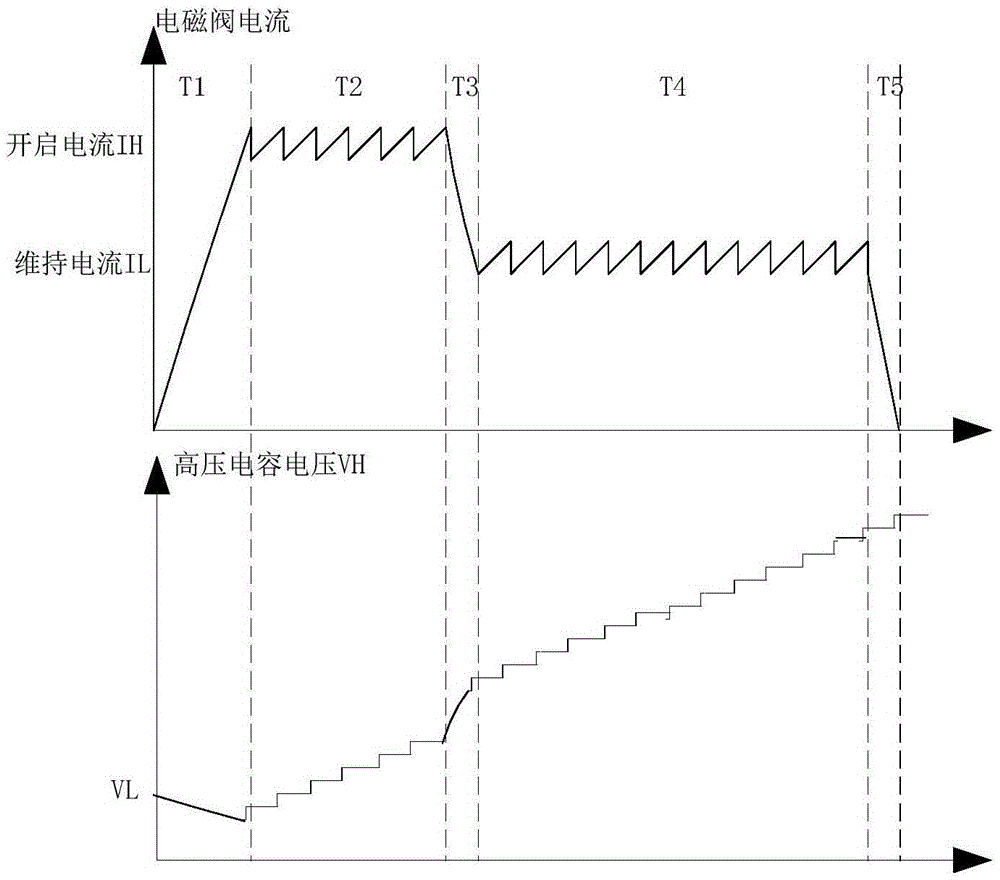

[0050] A high-speed solenoid valve driving method with boosting and fault diagnosis functions, comprising the following contents:

[0051] Utilize the inductance characteristics of the solenoid valve itself, use the solenoid valve as a power inductor to charge the high-voltage capacitor, drive the solenoid valve to work by controlling the on-off of the switch tube, and complete the boost function during this period;

[0052] If the voltage of the high-voltage capacitor does not reach the set value during the injection period, the voltage can continue to increase between two injections until the voltage reaches the set value; the voltage of the high-voltage capacitor is detected, and if t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com